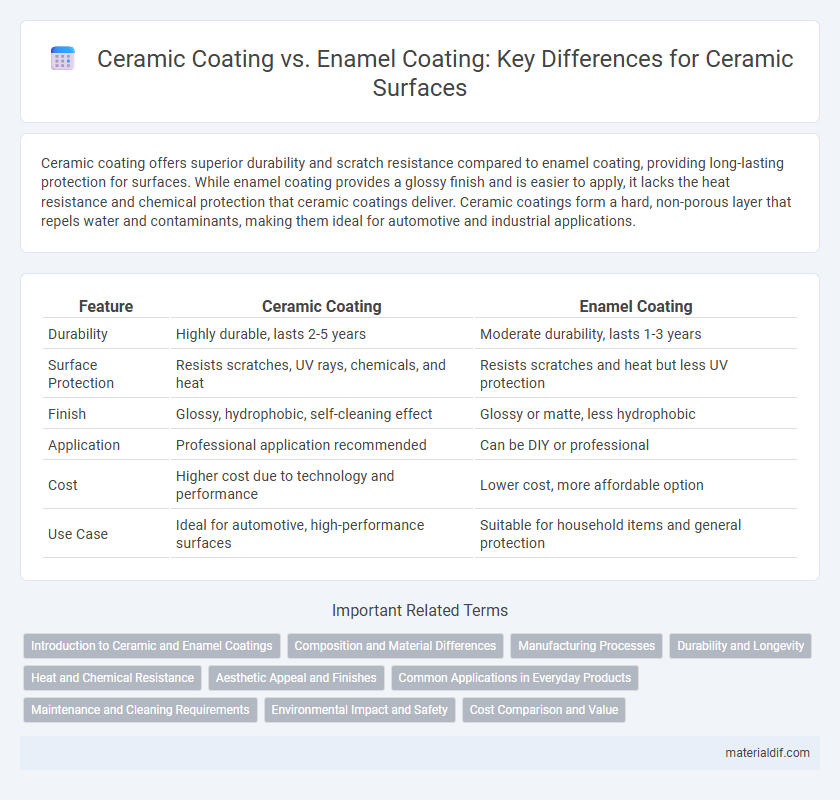

Ceramic coating offers superior durability and scratch resistance compared to enamel coating, providing long-lasting protection for surfaces. While enamel coating provides a glossy finish and is easier to apply, it lacks the heat resistance and chemical protection that ceramic coatings deliver. Ceramic coatings form a hard, non-porous layer that repels water and contaminants, making them ideal for automotive and industrial applications.

Table of Comparison

| Feature | Ceramic Coating | Enamel Coating |

|---|---|---|

| Durability | Highly durable, lasts 2-5 years | Moderate durability, lasts 1-3 years |

| Surface Protection | Resists scratches, UV rays, chemicals, and heat | Resists scratches and heat but less UV protection |

| Finish | Glossy, hydrophobic, self-cleaning effect | Glossy or matte, less hydrophobic |

| Application | Professional application recommended | Can be DIY or professional |

| Cost | Higher cost due to technology and performance | Lower cost, more affordable option |

| Use Case | Ideal for automotive, high-performance surfaces | Suitable for household items and general protection |

Introduction to Ceramic and Enamel Coatings

Ceramic coatings consist of silica-based polymers that form a durable, glass-like layer providing superior scratch resistance, UV protection, and hydrophobic properties. Enamel coatings are traditional paint layers made from synthetic resin and pigments, offering vibrant color with moderate durability and chemical resistance. Both coatings serve distinct functional and aesthetic purposes, with ceramic coatings excelling in long-term protection and enamel coatings favored for decorative finishes.

Composition and Material Differences

Ceramic coatings primarily consist of silicon dioxide (SiO2) or silicon carbide (SiC), forming a strong, glass-like layer that offers superior hardness and thermal resistance. Enamel coatings are composed mainly of powdered glass fused at high temperatures, creating a thick, durable layer often enriched with oxides for enhanced color and corrosion resistance. The fundamental material difference lies in ceramic's molecular structure delivering hardness and chemical stability, while enamel relies on glass fusion for strong adhesion and visual finish.

Manufacturing Processes

Ceramic coating manufacturing involves applying silicon dioxide (SiO2) or titanium dioxide (TiO2) nanoparticles through advanced chemical vapor deposition (CVD) or sol-gel techniques, producing a durable, heat-resistant surface. Enamel coating is created by fusing powdered glass or metal oxides onto a substrate at temperatures between 750degC and 850degC, resulting in a glossy, corrosion-resistant layer. The precision of ceramic nanocoating enhances surface hardness and chemical resistance, whereas enamel's vitrification process ensures strong adhesion and aesthetic appeal.

Durability and Longevity

Ceramic coatings offer superior durability compared to enamel coatings due to their advanced molecular structure, providing long-lasting protection against scratches, UV rays, and chemical damage. Enamel coatings, while effective for aesthetic finishes, tend to chip and degrade faster under harsh environmental conditions. The longevity of ceramic coatings typically exceeds five years with proper maintenance, significantly outperforming the average lifespan of enamel finishes.

Heat and Chemical Resistance

Ceramic coatings offer superior heat resistance, typically withstanding temperatures up to 1000degF (537degC), making them ideal for high-temperature applications like automotive exhausts and engine parts. Enamel coatings provide good chemical resistance against acids and alkalis but generally tolerate lower heat levels, usually up to 500degF (260degC). The enhanced thermal durability and strong chemical inertness of ceramic coatings make them preferable for environments involving extreme heat and aggressive chemicals.

Aesthetic Appeal and Finishes

Ceramic coating offers a high-gloss, mirror-like finish that enhances the depth and clarity of automotive paint, providing superior scratch resistance and long-lasting protection against environmental contaminants. Enamel coating typically delivers a thicker, more opaque finish with a smooth, durable surface that resists chipping and fading but lacks the reflective quality of ceramic. The choice between ceramic and enamel coatings depends on the desired aesthetic appeal, with ceramic favored for its sleek, glossy shine and enamel for its classic, robust finish.

Common Applications in Everyday Products

Ceramic coatings are commonly used in automotive paint protection, cookware, and electronic device screens due to their high durability, heat resistance, and scratch protection. Enamel coatings are frequently applied on household appliances, bathtubs, and outdoor furniture for their glossy finish, corrosion resistance, and easy maintenance. Both coatings enhance longevity and aesthetic appeal but cater to different functional requirements in everyday products.

Maintenance and Cleaning Requirements

Ceramic coatings provide a durable, hydrophobic layer that significantly reduces dirt adhesion and simplifies cleaning compared to traditional enamel coatings. Enamel coatings often require more frequent maintenance due to their lower resistance to scratches and staining. The self-cleaning properties of ceramic coatings result in less time and effort needed for upkeep, making them ideal for long-term protection.

Environmental Impact and Safety

Ceramic coatings are made from silica-based compounds that create a non-toxic, chemically stable layer, reducing the release of volatile organic compounds (VOCs) compared to traditional enamel coatings, which often contain heavy metals and solvents harmful to both the environment and human health. The durability and chemical resistance of ceramic coatings minimize the need for frequent reapplication, thereby lowering waste and environmental pollution. Enamel coatings, while effective in corrosion resistance, pose greater environmental hazards during production and disposal due to their toxic chemical constituents and the risk of bioaccumulation.

Cost Comparison and Value

Ceramic coating typically costs between $500 to $1,500 depending on vehicle size and quality, offering long-lasting protection with durability up to five years. Enamel coating is more affordable, averaging $100 to $300, but requires frequent reapplication every few months, impacting long-term value. Investing in ceramic coating provides higher upfront cost but greater cost-effectiveness over time due to superior resistance to scratches, chemicals, and environmental damage.

Ceramic Coating vs Enamel Coating Infographic

materialdif.com

materialdif.com