Ceramic membranes offer superior chemical resistance and thermal stability compared to polymer membranes, making them ideal for harsh industrial filtration applications. While polymer membranes are generally more cost-effective and flexible, ceramic membranes provide longer service life and higher durability under extreme conditions. Their inorganic nature allows for effective filtration of aggressive solvents and high-temperature processes that polymer membranes cannot withstand.

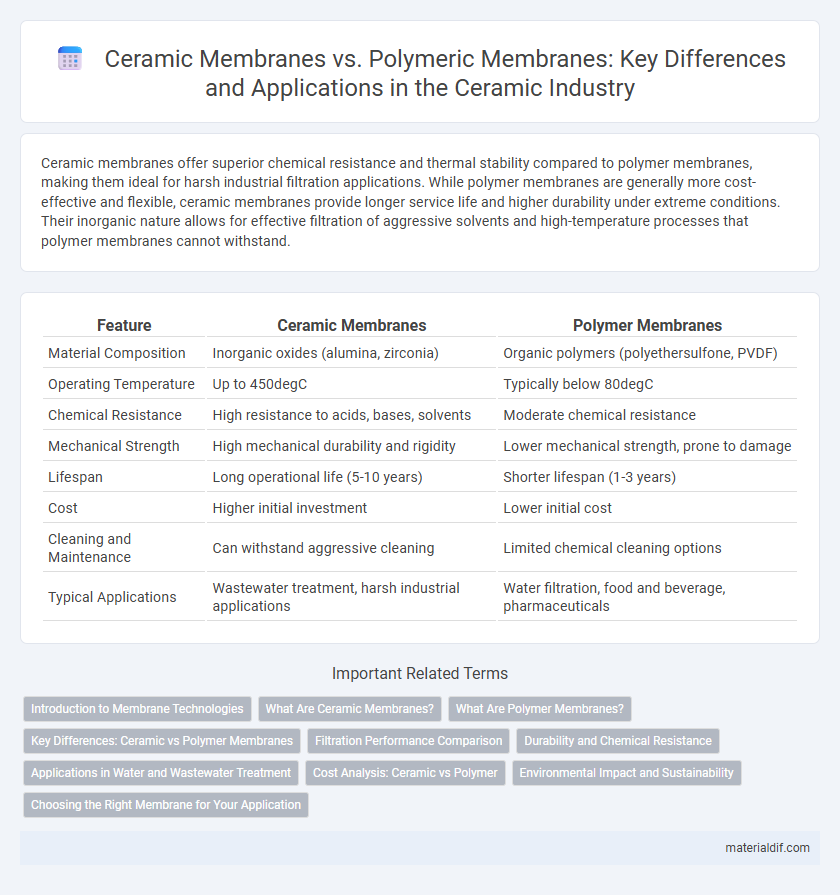

Table of Comparison

| Feature | Ceramic Membranes | Polymer Membranes |

|---|---|---|

| Material Composition | Inorganic oxides (alumina, zirconia) | Organic polymers (polyethersulfone, PVDF) |

| Operating Temperature | Up to 450degC | Typically below 80degC |

| Chemical Resistance | High resistance to acids, bases, solvents | Moderate chemical resistance |

| Mechanical Strength | High mechanical durability and rigidity | Lower mechanical strength, prone to damage |

| Lifespan | Long operational life (5-10 years) | Shorter lifespan (1-3 years) |

| Cost | Higher initial investment | Lower initial cost |

| Cleaning and Maintenance | Can withstand aggressive cleaning | Limited chemical cleaning options |

| Typical Applications | Wastewater treatment, harsh industrial applications | Water filtration, food and beverage, pharmaceuticals |

Introduction to Membrane Technologies

Ceramic membranes offer superior chemical and thermal stability compared to polymer membranes, making them ideal for harsh industrial applications such as wastewater treatment and gas separation. Polymer membranes provide greater flexibility and lower cost, widely used in water purification and gas filtration processes. The choice between ceramic and polymer membranes depends largely on the specific operational requirements including temperature, pH tolerance, and mechanical strength.

What Are Ceramic Membranes?

Ceramic membranes are filtration devices made from inorganic materials such as alumina, zirconia, or titania, known for their high thermal stability and chemical resistance. They offer superior durability and longevity compared to polymer membranes, withstanding extreme pH levels and elevated temperatures without degradation. These properties make ceramic membranes ideal for applications in harsh environments like wastewater treatment, food processing, and chemical separations.

What Are Polymer Membranes?

Polymer membranes are synthetic barriers primarily composed of organic polymers such as polysulfone, polyamide, or polyethylene, widely used in filtration and separation processes. These membranes offer flexibility, cost-effectiveness, and ease of fabrication, making them suitable for applications in water treatment, gas separation, and biomedical fields. Compared to ceramic membranes, polymer membranes generally exhibit lower chemical and thermal resistance but provide a broader range of pore sizes and higher permeability.

Key Differences: Ceramic vs Polymer Membranes

Ceramic membranes exhibit superior chemical and thermal stability compared to polymer membranes, making them ideal for harsh industrial applications. They offer higher mechanical strength and longer service life, while polymer membranes are typically more flexible and cost-effective. Ceramic membranes resist fouling and withstand aggressive cleaning processes, whereas polymer membranes are prone to degradation under extreme pH and temperature conditions.

Filtration Performance Comparison

Ceramic membranes offer superior filtration performance compared to polymer membranes due to their higher chemical and thermal stability, enabling operation under extreme pH and temperature conditions. Their smaller and more uniform pore size distribution results in enhanced contaminant removal efficiency and longer service life. Polymer membranes typically exhibit lower mechanical strength and are prone to fouling, which reduces filtration efficiency and increases maintenance costs.

Durability and Chemical Resistance

Ceramic membranes exhibit superior durability and chemical resistance compared to polymer membranes, making them ideal for harsh industrial applications involving extreme pH levels and high temperatures. Their inorganic composition allows ceramic membranes to withstand aggressive solvents and prolonged mechanical stress without degradation. Polymer membranes tend to suffer from swelling, fouling, and chemical attack, limiting their lifespan and performance in corrosive environments.

Applications in Water and Wastewater Treatment

Ceramic membranes offer superior chemical resistance and thermal stability compared to polymer membranes, making them ideal for harsh water and wastewater treatment environments. Their robust structure enables effective filtration of suspended solids, pathogens, and heavy metals, particularly in industrial effluents and high-temperature processes. Polymer membranes, while more cost-effective and flexible, are typically better suited for low-pressure applications with less aggressive contaminants.

Cost Analysis: Ceramic vs Polymer

Ceramic membranes typically incur higher initial costs due to raw material expenses and complex manufacturing processes, but their longer lifespan and superior chemical resistance reduce overall lifecycle expenses compared to polymer membranes. Polymer membranes offer lower upfront investments and greater flexibility, yet they often require more frequent replacement and maintenance, increasing cumulative operational costs. Cost analysis favors ceramic membranes in applications involving harsh environments and long-term use, while polymer membranes remain cost-effective for less demanding, short-term filtration needs.

Environmental Impact and Sustainability

Ceramic membranes exhibit superior environmental sustainability due to their longer lifespan, chemical resistance, and ability to be cleaned and reused multiple times, significantly reducing waste compared to polymer membranes. Polymer membranes often rely on non-biodegradable materials and require more frequent replacement, resulting in increased landfill contributions and higher environmental burdens. The energy consumption for producing ceramic membranes is higher initially, but their durability and lower operational waste promote a more sustainable lifecycle in water treatment and filtration applications.

Choosing the Right Membrane for Your Application

Ceramic membranes offer superior chemical resistance, thermal stability, and durability compared to polymer membranes, making them ideal for harsh industrial applications such as wastewater treatment and chemical processing. Polymer membranes provide greater flexibility, cost-effectiveness, and ease of installation, suitable for applications requiring lower temperature and mild chemical environments like food processing and pharmaceuticals. Selecting the right membrane depends on factors such as operational temperature, pH tolerance, chemical exposure, and budget constraints to optimize performance and longevity.

Ceramic Membranes vs Polymer Membranes Infographic

materialdif.com

materialdif.com