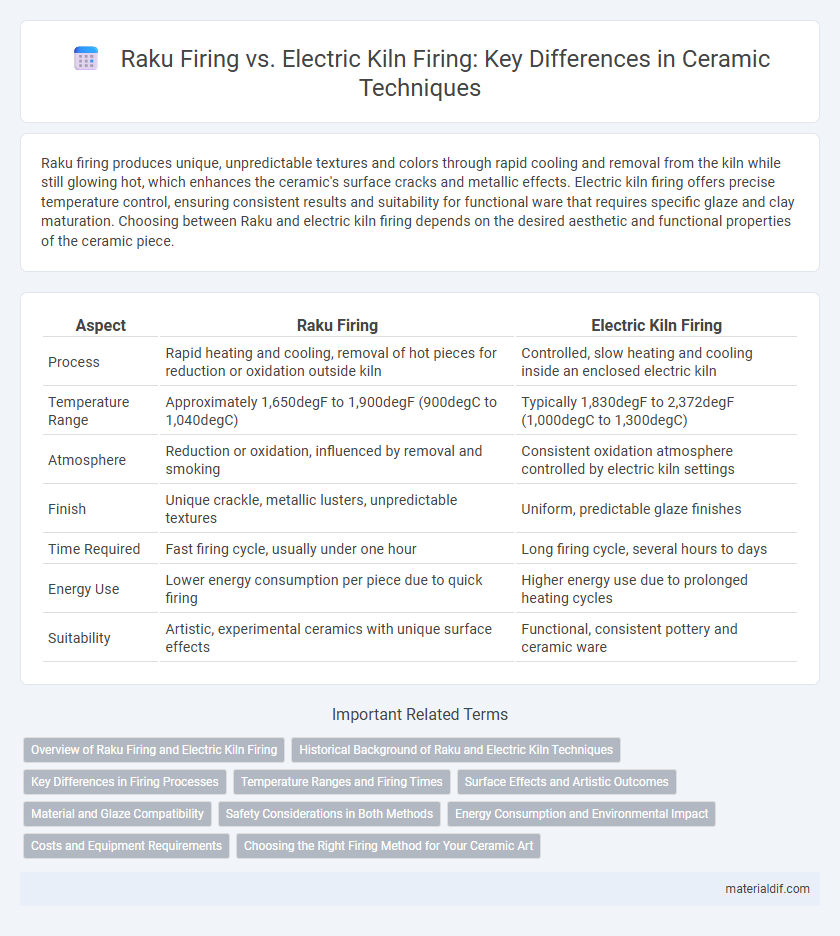

Raku firing produces unique, unpredictable textures and colors through rapid cooling and removal from the kiln while still glowing hot, which enhances the ceramic's surface cracks and metallic effects. Electric kiln firing offers precise temperature control, ensuring consistent results and suitability for functional ware that requires specific glaze and clay maturation. Choosing between Raku and electric kiln firing depends on the desired aesthetic and functional properties of the ceramic piece.

Table of Comparison

| Aspect | Raku Firing | Electric Kiln Firing |

|---|---|---|

| Process | Rapid heating and cooling, removal of hot pieces for reduction or oxidation outside kiln | Controlled, slow heating and cooling inside an enclosed electric kiln |

| Temperature Range | Approximately 1,650degF to 1,900degF (900degC to 1,040degC) | Typically 1,830degF to 2,372degF (1,000degC to 1,300degC) |

| Atmosphere | Reduction or oxidation, influenced by removal and smoking | Consistent oxidation atmosphere controlled by electric kiln settings |

| Finish | Unique crackle, metallic lusters, unpredictable textures | Uniform, predictable glaze finishes |

| Time Required | Fast firing cycle, usually under one hour | Long firing cycle, several hours to days |

| Energy Use | Lower energy consumption per piece due to quick firing | Higher energy use due to prolonged heating cycles |

| Suitability | Artistic, experimental ceramics with unique surface effects | Functional, consistent pottery and ceramic ware |

Overview of Raku Firing and Electric Kiln Firing

Raku firing is a rapid, low-temperature ceramic firing technique that produces unique surface textures and unpredictable glaze effects through immediate cooling and reduction processes. Electric kiln firing offers precise temperature control and consistent firing conditions, enabling higher temperatures suited for durable stoneware and porcelain creations. The distinct cooling methods and firing atmospheres fundamentally differentiate Raku from electric kiln processes, impacting the final ceramic aesthetics and structural properties.

Historical Background of Raku and Electric Kiln Techniques

Raku firing originated in 16th-century Japan as a hands-on, rapid cooling pottery technique linked to the tea ceremony, emphasizing spontaneity and unique glaze effects. In contrast, electric kiln firing developed with advancements in industrial technology during the 20th century, offering precise temperature control and consistent results for mass ceramic production. The historical roots of raku emphasize artisanal craftsmanship, while electric kilns represent modern efficiency and repeatability in ceramic firing.

Key Differences in Firing Processes

Raku firing involves rapidly heating ceramics in a gas-powered kiln followed by quick removal and cooling in open air or combustible materials, creating unique crackle patterns and unpredictable surface effects. Electric kiln firing uses controlled, gradual heating and cooling cycles within an enclosed environment, ensuring consistent temperature and less thermal shock, resulting in more uniform glaze finishes. The key differences lie in the temperature ramp rate, cooling method, and the level of control over oxygen exposure, which significantly impact the texture, color, and overall aesthetic of the ceramic pieces.

Temperature Ranges and Firing Times

Raku firing typically occurs at lower temperatures ranging from 1,650degF to 1,830degF (900degC to 1,000degC) and involves rapid firing cycles lasting 30 to 60 minutes, which allows for unique surface effects due to thermal shock and reduction. Electric kiln firing operates at higher, more controlled temperatures generally between 1,830degF and 2,300degF (1,000degC to 1,260degC) with firing times extending from several hours up to 24 hours to achieve consistent glaze maturation and ceramic strength. The distinct temperature ranges and firing durations between Raku and electric kiln firing influence the physical properties and aesthetic outcomes of ceramic pieces.

Surface Effects and Artistic Outcomes

Raku firing produces unique surface effects characterized by crackled glazes, metallic lusters, and unpredictable patterns due to rapid cooling and smoke exposure, enhancing the artistic spontaneity of ceramic pieces. Electric kiln firing offers more controlled, consistent results with smooth, evenly melted glazes and vibrant colors ideal for precision and repeatability in ceramic art. Artists choose Raku for its organic, textured finishes and electric kilns for refined, polished surface effects, tailoring outcomes to their creative vision.

Material and Glaze Compatibility

Raku firing involves rapid heating and cooling, which is suitable for porous clay bodies like stoneware and porous glazes that can withstand thermal shock, while electric kiln firing accommodates a wider range of materials including porcelain and high-fire stoneware. Glazes used in Raku must be formulated to tolerate explosive expansion and contraction, often resulting in crackled or metallic effects, whereas electric kiln glazes offer more durability and uniform finishes due to gradual temperature changes. Material compatibility with each firing method directly influences glaze outcome, texture, and structural integrity in ceramic pieces.

Safety Considerations in Both Methods

Raku firing involves rapid heating and cooling cycles, which can produce toxic fumes and requires proper ventilation and protective gear to ensure safety. Electric kiln firing offers a more controlled environment with minimal exposure to hazardous gases, but high temperatures demand careful handling and heat-resistant equipment to prevent burns. Both methods necessitate strict adherence to safety protocols to avoid accidents and health risks during the firing process.

Energy Consumption and Environmental Impact

Raku firing consumes significantly less energy than electric kiln firing due to its rapid heating and cooling cycles, which typically last only minutes compared to hours in electric kilns. The open-air combustion in raku sends volatile organic compounds and particulate matter into the atmosphere, increasing its environmental impact despite lower energy use. Conversely, electric kilns offer controlled emissions and the potential for cleaner energy sources but require higher electricity consumption, contributing to a larger carbon footprint depending on the energy mix.

Costs and Equipment Requirements

Raku firing requires specialized equipment like a raku kiln, fuel sources such as propane, and protective gear, often leading to higher initial setup costs compared to electric kiln firing. Electric kilns involve lower upfront investment and operating costs due to their efficiency and ease of use, making them more accessible for beginners and small studios. Maintenance expenses for raku equipment can be higher because of the intense thermal shock involved, whereas electric kilns typically have longer lifespans and lower repair needs.

Choosing the Right Firing Method for Your Ceramic Art

Raku firing offers unique, unpredictable surface textures and rapid cooling effects that enhance the artistic expression of ceramic pieces, making it ideal for artists seeking spontaneity and organic finishes. Electric kiln firing provides precise temperature control and consistent results, supporting the creation of durable, functional ceramics with fine glazes. Selecting the right firing method depends on the desired aesthetic, the type of clay body used, and the functional requirements of the ceramic artwork.

Raku Firing vs Electric Kiln Firing Infographic

materialdif.com

materialdif.com