Vitrification in ceramics involves heating materials until they partially melt, creating a glassy, non-porous structure that enhances durability and water resistance in ceramic pets. Sintering, by contrast, heats powdered materials below their melting point, allowing particles to fuse through diffusion, resulting in a strong but often more porous ceramic body. Choosing between vitrification and sintering affects the pet's finish and strength, with vitrification providing a smoother, denser surface ideal for longevity.

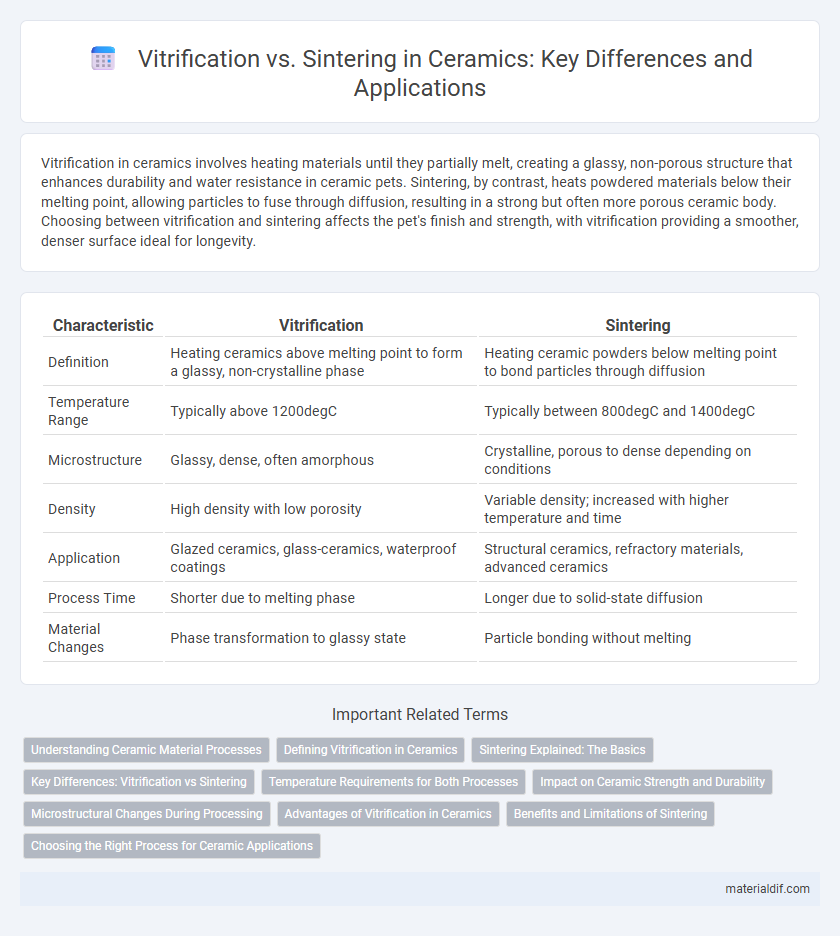

Table of Comparison

| Characteristic | Vitrification | Sintering |

|---|---|---|

| Definition | Heating ceramics above melting point to form a glassy, non-crystalline phase | Heating ceramic powders below melting point to bond particles through diffusion |

| Temperature Range | Typically above 1200degC | Typically between 800degC and 1400degC |

| Microstructure | Glassy, dense, often amorphous | Crystalline, porous to dense depending on conditions |

| Density | High density with low porosity | Variable density; increased with higher temperature and time |

| Application | Glazed ceramics, glass-ceramics, waterproof coatings | Structural ceramics, refractory materials, advanced ceramics |

| Process Time | Shorter due to melting phase | Longer due to solid-state diffusion |

| Material Changes | Phase transformation to glassy state | Particle bonding without melting |

Understanding Ceramic Material Processes

Vitrification in ceramics involves melting the material to form a glassy, non-porous phase that enhances strength and reduces permeability. Sintering, by contrast, compacts powdered ceramics through heat below the melting point, promoting particle bonding and densification without liquefaction. Understanding these processes is crucial for optimizing ceramic properties such as hardness, durability, and thermal resistance in industrial applications.

Defining Vitrification in Ceramics

Vitrification in ceramics refers to the process where materials are heated until they form a glassy, non-crystalline solid, significantly reducing porosity and increasing strength. This transformation occurs as the molten phase fills the spaces between particles, resulting in a dense, impermeable structure. Unlike sintering, which primarily involves particle bonding without melting, vitrification leads to glass formation that enhances durability and resistance to water absorption.

Sintering Explained: The Basics

Sintering in ceramics involves heating powdered materials below their melting point to facilitate particle bonding through diffusion mechanisms. This process enhances mechanical strength, density, and structural integrity by eliminating porosity without reaching vitrification temperatures. Control over sintering parameters such as temperature, time, and atmosphere directly influences grain growth and microstructure development, critical for optimizing ceramic properties.

Key Differences: Vitrification vs Sintering

Vitrification in ceramics involves the transformation of materials into a glass-like, non-crystalline solid through heating, resulting in increased density and impermeability. Sintering, on the other hand, is a process where powdered ceramic particles are fused together by heat without melting, enhancing mechanical strength and structural integrity. The key difference lies in vitrification producing a glassy phase that reduces porosity, whereas sintering primarily consolidates particles without necessarily creating a vitreous matrix.

Temperature Requirements for Both Processes

Vitrification in ceramics requires higher temperatures, typically above 1200degC, to achieve glassy, non-porous microstructures through melting and cooling. Sintering occurs at lower temperatures, usually between 800degC and 1300degC, where particles bond without complete melting, preserving the ceramic's granular structure. Understanding these temperature requirements is crucial for optimizing mechanical strength and thermal properties in ceramic manufacturing.

Impact on Ceramic Strength and Durability

Vitrification involves melting ceramic particles into a glassy phase, significantly enhancing strength and durability by reducing porosity and increasing density. Sintering, a lower-temperature process, fuses particles through solid-state diffusion, improving mechanical properties while preserving some porosity for toughness. The choice between vitrification and sintering affects the ceramic's microstructure, influencing its resistance to wear, thermal shock, and mechanical stress.

Microstructural Changes During Processing

Vitrification in ceramics involves the formation of a glassy phase that fills pores, resulting in a dense, non-porous microstructure and enhanced mechanical strength. Sintering primarily promotes particle bonding and densification through solid-state diffusion, leading to grain growth and reduced porosity without necessarily forming a glassy phase. Microstructural changes during vitrification include the transformation of crystalline phases into an amorphous matrix, while sintering maintains crystalline integrity with neck formation between particles and grain boundary evolution.

Advantages of Vitrification in Ceramics

Vitrification in ceramics creates a dense, glass-like structure that enhances strength, durability, and water resistance compared to sintering. This process reduces porosity significantly, leading to improved hardness and lower permeability, which is crucial for high-performance applications such as tiles and sanitary ware. The advanced mechanical properties and enhanced chemical stability resulting from vitrification make it superior for producing long-lasting ceramic products.

Benefits and Limitations of Sintering

Sintering enhances ceramic density and mechanical strength by heating powdered materials below their melting points, promoting particle bonding without liquefaction. Benefits include reduced porosity, improved thermal stability, and cost efficiency, making it ideal for complex shapes and high-volume production. Limitations involve potential grain growth affecting toughness, longer processing times, and constraints in achieving full vitrification compared to vitrification methods.

Choosing the Right Process for Ceramic Applications

Vitrification and sintering are critical processes in ceramic manufacturing, each suited to specific applications based on desired material properties. Vitrification produces a glass-like, non-porous structure ideal for waterproof and high-strength ceramics, while sintering enhances density and mechanical strength without melting the material. Selecting the right process depends on factors like thermal stability, porosity requirements, and end-use durability in applications such as tiles, insulators, or cutting tools.

Vitrification vs Sintering Infographic

materialdif.com

materialdif.com