Isostatic pressing ensures uniform pressure application from all directions, resulting in consistent density and fewer defects in ceramic components. Dry pressing applies uniaxial pressure, which can lead to density gradients and potential weak points within the ceramic structure. For high-performance ceramics requiring structural integrity and precision, isostatic pressing provides superior material properties compared to dry pressing.

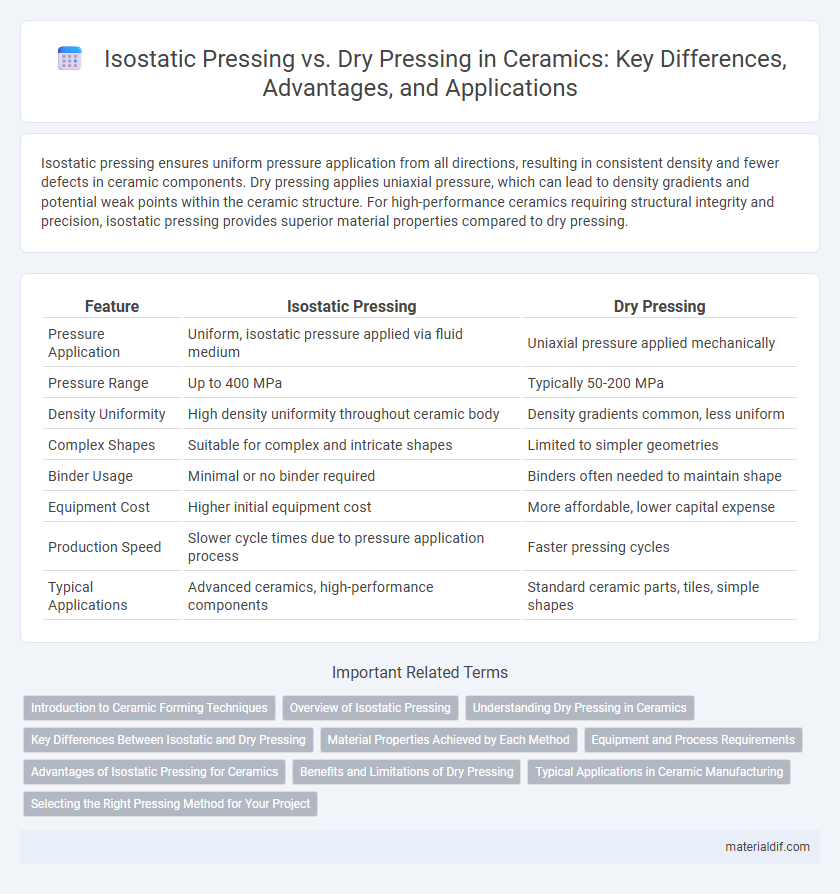

Table of Comparison

| Feature | Isostatic Pressing | Dry Pressing |

|---|---|---|

| Pressure Application | Uniform, isostatic pressure applied via fluid medium | Uniaxial pressure applied mechanically |

| Pressure Range | Up to 400 MPa | Typically 50-200 MPa |

| Density Uniformity | High density uniformity throughout ceramic body | Density gradients common, less uniform |

| Complex Shapes | Suitable for complex and intricate shapes | Limited to simpler geometries |

| Binder Usage | Minimal or no binder required | Binders often needed to maintain shape |

| Equipment Cost | Higher initial equipment cost | More affordable, lower capital expense |

| Production Speed | Slower cycle times due to pressure application process | Faster pressing cycles |

| Typical Applications | Advanced ceramics, high-performance components | Standard ceramic parts, tiles, simple shapes |

Introduction to Ceramic Forming Techniques

Isostatic pressing applies uniform pressure from all directions, resulting in highly dense and uniform ceramic components with superior mechanical properties compared to dry pressing, which uses uniaxial pressure and may cause density gradients. This technique is ideal for complex shapes and materials sensitive to pressure variations, enhancing green body strength and reducing defects. Understanding the differences between isostatic and dry pressing is crucial for selecting the appropriate forming method based on material behavior and final application requirements in ceramic manufacturing.

Overview of Isostatic Pressing

Isostatic pressing applies uniform pressure from all directions using a fluid medium, resulting in highly dense and isotropic ceramic components. This process eliminates density gradients common in dry pressing, enhancing mechanical properties and minimizing defects. Isostatic pressing is ideal for complex shapes and materials requiring consistent microstructure and superior strength.

Understanding Dry Pressing in Ceramics

Dry pressing in ceramics involves compressing powder materials within a rigid die at high pressure to form uniform, dense green bodies with minimal binder usage. This method offers precise control over shape and density, making it ideal for producing simple geometries in large quantities with consistent mechanical properties. Unlike isostatic pressing, dry pressing applies uniaxial pressure, which can lead to density gradients but is more cost-effective and efficient for standard ceramic components.

Key Differences Between Isostatic and Dry Pressing

Isostatic pressing applies uniform pressure from all directions using a fluid medium, resulting in improved density and reduced porosity in ceramic components compared to dry pressing, which applies uniaxial pressure typically using a mechanical press. Dry pressing is more cost-effective and suitable for simple shapes but often produces less uniform density and mechanical strength. Isostatic pressing enables complex geometries and higher performance ceramics by minimizing defects and achieving isotropic material properties.

Material Properties Achieved by Each Method

Isostatic pressing produces ceramics with superior uniform density and enhanced mechanical strength due to the equal pressure applied from all directions, minimizing internal defects. Dry pressing often results in anisotropic density distribution, which can cause variations in hardness and increased porosity, impacting overall durability. Materials formed through isostatic pressing typically exhibit improved fracture toughness and better sintering behavior compared to those shaped by dry pressing.

Equipment and Process Requirements

Isostatic pressing requires specialized equipment such as flexible molds and high-pressure vessels capable of applying uniform pressure from all directions, enabling the consistent densification of complex-shaped ceramic parts. Dry pressing uses rigid molds and hydraulic or mechanical presses to apply uniaxial pressure, which is simpler and less costly but may cause density gradients in the ceramic compact. The isostatic pressing process demands precise control of pressure and mold flexibility, while dry pressing emphasizes mold design and press force for achieving desired part geometry and density.

Advantages of Isostatic Pressing for Ceramics

Isostatic pressing offers uniform pressure distribution, resulting in ceramics with higher density and improved mechanical properties compared to dry pressing. This method enhances material homogeneity and reduces internal defects, leading to superior structural integrity and performance. The ability to compact complex shapes with consistent quality makes isostatic pressing advantageous for advanced ceramic manufacturing.

Benefits and Limitations of Dry Pressing

Dry pressing offers benefits such as cost-effectiveness, simplicity, and suitability for forming ceramic powders with uniform particle size, enabling high production rates and consistent part density. However, its limitations include restrictions on complex geometries, lower achievable densities compared to isostatic pressing, and potential density gradients within the pressed part leading to mechanical weaknesses. The process is widely used in manufacturing flat, simple-shaped ceramic components where dimensional tolerances and surface finish are less critical.

Typical Applications in Ceramic Manufacturing

Isostatic pressing is commonly used in the production of complex-shaped ceramic components such as advanced aerospace parts, biomedical implants, and high-performance electronic substrates, where uniform pressure application ensures homogeneity and reduces flaws. Dry pressing is typically applied in manufacturing simple shapes like ceramic tiles, insulators, and automotive components, benefiting from its cost-effectiveness and high throughput. Both techniques play crucial roles in ceramic manufacturing by optimizing density and mechanical properties tailored to specific application requirements.

Selecting the Right Pressing Method for Your Project

Isostatic pressing offers uniform pressure application, resulting in higher density and improved mechanical properties for complex ceramic shapes, while dry pressing is cost-effective and suitable for simple, flat components with consistent thickness. Selecting the right pressing method depends on factors such as part geometry, desired material density, production volume, and cost constraints. Engineers evaluating ceramic fabrication should prioritize isostatic pressing for intricate or high-performance applications and dry pressing for straightforward designs and economical manufacturing.

Isostatic Pressing vs Dry Pressing Infographic

materialdif.com

materialdif.com