Redware ceramics are distinguished by their natural reddish clay, offering a rustic and earthy appearance favored for decorative pottery and cookware. Whiteware, made from refined white clay, provides a smooth texture and bright finish ideal for tableware and ornamental pieces. Both types vary in durability and firing temperature, influencing their suitability for different pet accessories and decorative uses.

Table of Comparison

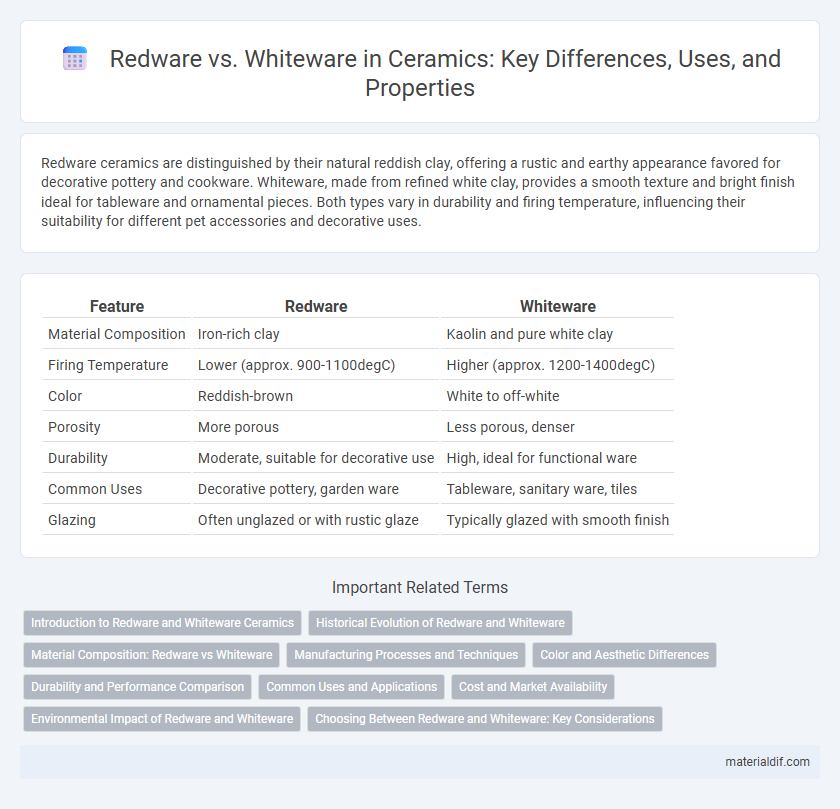

| Feature | Redware | Whiteware |

|---|---|---|

| Material Composition | Iron-rich clay | Kaolin and pure white clay |

| Firing Temperature | Lower (approx. 900-1100degC) | Higher (approx. 1200-1400degC) |

| Color | Reddish-brown | White to off-white |

| Porosity | More porous | Less porous, denser |

| Durability | Moderate, suitable for decorative use | High, ideal for functional ware |

| Common Uses | Decorative pottery, garden ware | Tableware, sanitary ware, tiles |

| Glazing | Often unglazed or with rustic glaze | Typically glazed with smooth finish |

Introduction to Redware and Whiteware Ceramics

Redware ceramics are earthenware products characterized by their reddish clay body, which contains iron oxide, giving them a distinct warm hue and a porous texture ideal for decorative pottery and traditional cookware. Whiteware ceramics, on the other hand, utilize refined clays with low iron content, producing a white or light-colored body that is highly durable and commonly used for functional wares such as dinnerware, sanitary ware, and tiles. The choice between redware and whiteware depends on factors like firing temperature, intended use, and aesthetic preference, with redware typically firing at lower temperatures and whiteware achieving higher vitrification levels.

Historical Evolution of Redware and Whiteware

Redware ceramics, characterized by their iron-rich clay body, originated in ancient civilizations such as Mesopotamia and continued to evolve through the Roman period, valued for its durability and vibrant reddish hue. Whiteware, distinguished by its kaolin-rich, white clay body, emerged prominently in the 18th century with advancements in porcelain manufacturing, emphasizing refined aesthetics and translucency. The historical evolution of both redware and whiteware reflects technological innovations, shifts in cultural preferences, and the expansion of trade networks influencing ceramic production worldwide.

Material Composition: Redware vs Whiteware

Redware is primarily composed of iron-rich clays that give it its distinctive reddish-brown color, making it porous and suitable for earthenware pottery. Whiteware, on the other hand, is made from kaolin and other light-colored clays combined with fluxes and fillers, resulting in a dense, white, and often vitrified body ideal for fine ceramics and porcelain. The material composition differences influence firing temperatures, porosity, and durability, with redware typically fired at lower temperatures than whiteware.

Manufacturing Processes and Techniques

Redware ceramics are typically crafted from iron-rich clays that are fired at lower temperatures, resulting in their distinctive reddish hue and porous texture. Whiteware, in contrast, utilizes kaolin or other light-colored clays fired at higher temperatures, producing a denser, more vitrified body with a smooth white appearance. Techniques for redware often involve simpler glazing processes due to its absorbent nature, whereas whiteware requires precise glazing methods to achieve its durable, non-porous finish.

Color and Aesthetic Differences

Redware ceramics are characterized by their rich, earthy red to terracotta hues, resulting from iron oxide in the clay, offering a warm and rustic aesthetic ideal for traditional or folk art designs. Whiteware ceramics feature a pale, often brilliant white or off-white finish due to purified white clays like kaolin, providing a clean, crisp appearance suited for modern, minimalist, or fine china applications. The distinct color bases influence glazing choices and decorative techniques, with redware's porous surface often showcasing matte finishes and whiteware enabling glossy, intricate painted details.

Durability and Performance Comparison

Redware ceramics exhibit superior durability due to their iron-rich clay composition, which enhances strength and resistance to chipping compared to whiteware. Whiteware, made from refined kaolin and firing at higher temperatures, offers a smoother, more delicate finish but is generally more prone to cracking under thermal stress. Performance-wise, redware excels in outdoor and utilitarian applications, while whiteware is preferred for fine dining and decorative purposes where aesthetic finesse is prioritized.

Common Uses and Applications

Redware ceramics, made from iron-rich clay, are commonly used for flower pots, cookware, and traditional dinnerware due to their porous nature and rustic appearance. Whiteware, crafted from refined kaolin clay, finds applications in fine china, sanitary ware, and electrical insulators because of its durable, non-porous, and aesthetically smooth surface. Both types serve essential roles in household and industrial contexts, with redware favored for utilitarian and decorative purposes, while whiteware dominates in precision and hygienic applications.

Cost and Market Availability

Redware ceramics, typically made from iron-rich clay, are generally more affordable due to the abundance and lower processing costs of raw materials. Whiteware, crafted from refined kaolin and feldspar, demands higher production expenses which results in increased market prices. Redware's widespread availability in traditional markets contrasts with whiteware's dominance in commercial and fine dining sectors, indicating distinct cost and accessibility dynamics.

Environmental Impact of Redware and Whiteware

Redware ceramics, typically fired at lower temperatures using iron-rich clays, generally have a smaller carbon footprint due to reduced energy consumption during production compared to whiteware, which requires higher firing temperatures and often utilizes kaolin clay. Whiteware's production process often involves more intensive mining and refining of raw materials, leading to greater resource depletion and higher greenhouse gas emissions. However, redware's porous nature may necessitate additional glazing or sealing treatments that can offset some environmental savings.

Choosing Between Redware and Whiteware: Key Considerations

Choosing between redware and whiteware depends primarily on their material properties and intended use; redware, made from iron-rich clay, offers durability and a rustic aesthetic ideal for functional pottery and outdoor pieces, while whiteware, composed of refined clays like kaolin, provides a smooth, bright surface perfect for fine china and decorative ceramics. Consider firing temperature and glaze compatibility, as redware typically matures at lower temperatures compared to whiteware, influencing glaze options and final appearance. Cost and availability also play roles; redware tends to be more affordable and accessible, whereas whiteware requires more precise processing and higher-quality raw materials.

Redware vs Whiteware Infographic

materialdif.com

materialdif.com