Vitrified ceramic is denser and less porous than non-vitrified ceramic, making it more durable and water-resistant, ideal for pet bowls and habitats that require frequent cleaning. Non-vitrified ceramic tends to absorb moisture and is more prone to chipping, which may pose hygiene challenges and reduce longevity. Choosing vitrified ceramic ensures a safer, long-lasting option for pet accessories with enhanced resistance to wear and bacterial growth.

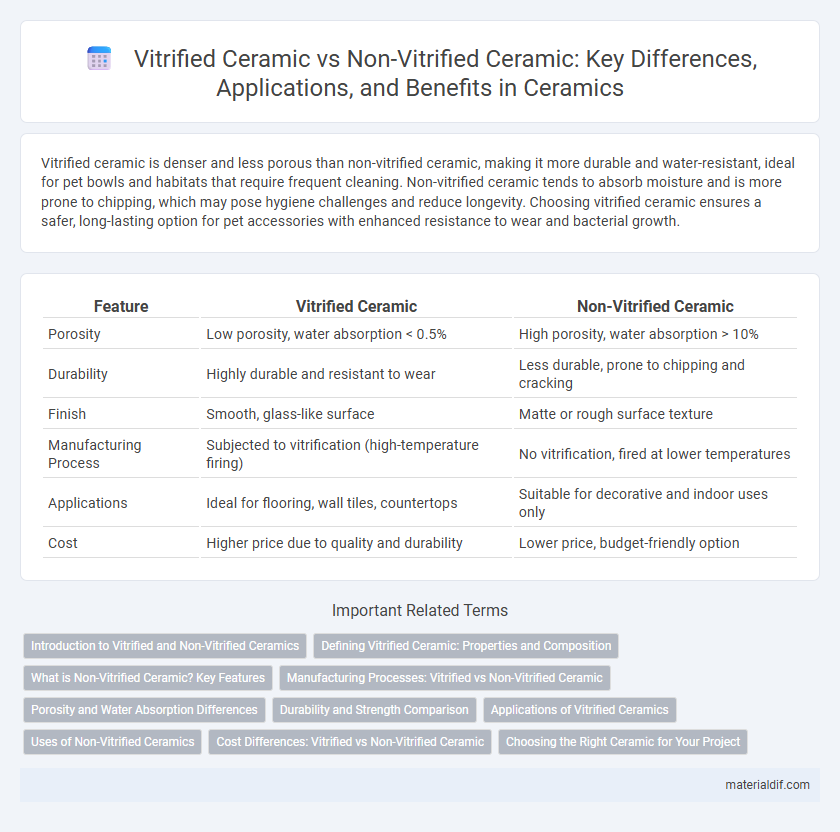

Table of Comparison

| Feature | Vitrified Ceramic | Non-Vitrified Ceramic |

|---|---|---|

| Porosity | Low porosity, water absorption < 0.5% | High porosity, water absorption > 10% |

| Durability | Highly durable and resistant to wear | Less durable, prone to chipping and cracking |

| Finish | Smooth, glass-like surface | Matte or rough surface texture |

| Manufacturing Process | Subjected to vitrification (high-temperature firing) | No vitrification, fired at lower temperatures |

| Applications | Ideal for flooring, wall tiles, countertops | Suitable for decorative and indoor uses only |

| Cost | Higher price due to quality and durability | Lower price, budget-friendly option |

Introduction to Vitrified and Non-Vitrified Ceramics

Vitrified ceramics undergo a high-temperature firing process that fuses particles into a dense, glass-like structure, enhancing durability and water resistance. Non-vitrified ceramics are fired at lower temperatures, resulting in a more porous and less dense material with higher water absorption rates. These fundamental differences affect their applications, with vitrified ceramics commonly used for floor tiles and outdoor installations, while non-vitrified ceramics suit indoor wall tiles and decorative items.

Defining Vitrified Ceramic: Properties and Composition

Vitrified ceramic is characterized by its dense, glass-like surface achieved through high-temperature firing, resulting in low porosity and enhanced durability. The composition typically includes a blend of clay, feldspar, and silica, which fuse to form a non-porous, rigid structure resistant to moisture and stains. This makes vitrified ceramics ideal for applications requiring strength and water resistance, contrasting with non-vitrified ceramics that remain porous and less durable.

What is Non-Vitrified Ceramic? Key Features

Non-vitrified ceramic is a type of ceramic material characterized by its porous and absorbent nature due to incomplete vitrification during firing. Key features include higher water absorption rates, lower density, and a rougher texture compared to vitrified ceramics, making it less suitable for applications requiring high durability and moisture resistance. It is commonly used in decorative tiles and indoor flooring where moisture exposure is minimal.

Manufacturing Processes: Vitrified vs Non-Vitrified Ceramic

Vitrified ceramics undergo a high-temperature firing process that causes the clay and other materials to fuse, resulting in a dense, glass-like surface with minimal porosity. Non-vitrified ceramics are fired at lower temperatures, leaving a more porous structure that absorbs water and is less durable. The manufacturing distinction directly impacts the final product's resistance to moisture, strength, and suitability for different applications such as flooring and wall tiles.

Porosity and Water Absorption Differences

Vitrified ceramic exhibits significantly lower porosity and water absorption rates compared to non-vitrified ceramic due to its dense, glass-like surface formed during high-temperature firing. Non-vitrified ceramic remains more porous and absorbs higher amounts of water, making it less suitable for high-moisture environments. The reduced porosity in vitrified ceramic enhances durability, stain resistance, and frost resistance, making it ideal for flooring and sanitary applications.

Durability and Strength Comparison

Vitrified ceramic exhibits superior durability and strength due to its low porosity and dense composition achieved through high-temperature firing, making it highly resistant to wear, water absorption, and staining. Non-vitrified ceramic, by contrast, has a more porous structure, leading to lower mechanical strength and increased susceptibility to moisture damage and surface degradation over time. This inherent difference makes vitrified ceramic the preferred choice for high-traffic areas and demanding applications requiring long-lasting performance.

Applications of Vitrified Ceramics

Vitrified ceramics are widely used in applications requiring high durability and low water absorption, such as floor tiles in commercial and industrial settings. Their dense, non-porous surface makes them ideal for heavy-traffic areas, bathrooms, kitchens, and outdoor spaces where resistance to stains, moisture, and wear is essential. Unlike non-vitrified ceramics, vitrified types offer superior strength, making them suitable for both residential and large-scale infrastructure projects.

Uses of Non-Vitrified Ceramics

Non-vitrified ceramics are highly porous and exhibit excellent water absorption, making them ideal for indoor flooring in low-moisture environments like residential areas and commercial spaces. Their rough texture provides good slip resistance, which is beneficial for areas requiring nonslip surfaces such as patios and walkways. These ceramics are also commonly used in decorative wall cladding and artistic applications where durability is important but water resistance is less critical.

Cost Differences: Vitrified vs Non-Vitrified Ceramic

Vitrified ceramic tiles typically cost more than non-vitrified ceramic due to their denser composition and advanced manufacturing process that enhances durability and resistance to water absorption. Non-vitrified ceramic tiles are more budget-friendly but are less durable and more porous, requiring additional sealing and maintenance over time. The higher upfront cost of vitrified ceramics is often offset by their long-term performance and reduced maintenance expenses.

Choosing the Right Ceramic for Your Project

Vitrified ceramic offers enhanced durability, low porosity, and superior resistance to moisture and stains, making it ideal for high-traffic areas and outdoor projects. Non-vitrified ceramic, being more porous and cost-effective, suits decorative applications and indoor spaces with lower wear and tear. Selecting the right ceramic depends on the project's functional requirements, environmental exposure, and budget considerations.

Vitrified Ceramic vs Non-Vitrified Ceramic Infographic

materialdif.com

materialdif.com