Ceramic slip casting offers precise replication of complex shapes by pouring liquid clay into molds, ensuring uniform thickness and fine surface texture. Hand building allows for more artistic freedom and individuality, using techniques like coiling and pinching to shape clay without molds. Both methods complement different creative goals, with slip casting favoring consistency and hand building embracing tactile craftsmanship.

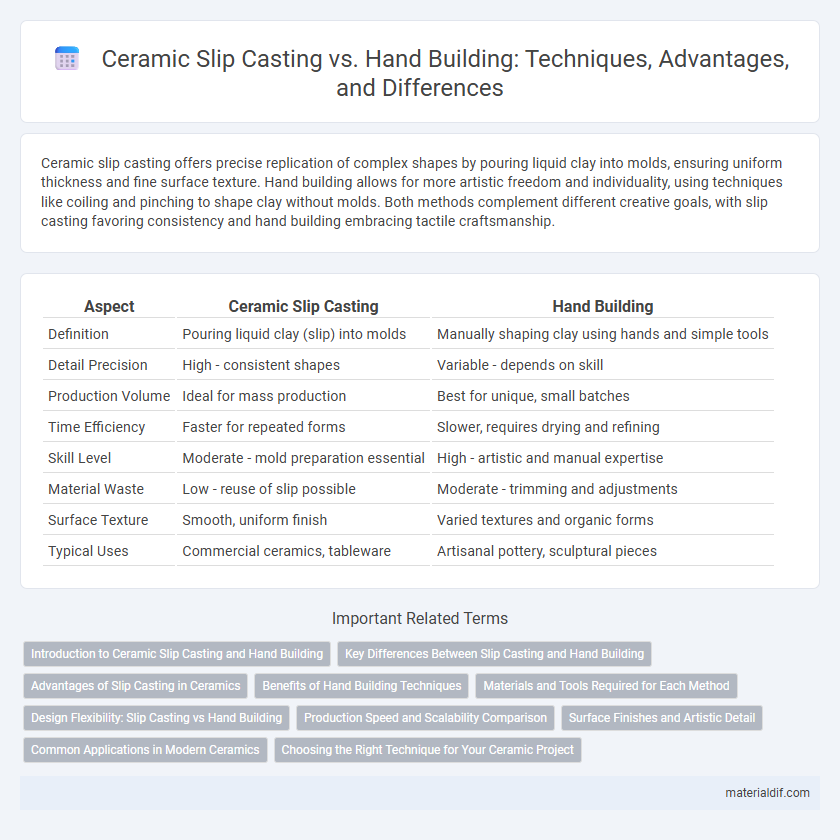

Table of Comparison

| Aspect | Ceramic Slip Casting | Hand Building |

|---|---|---|

| Definition | Pouring liquid clay (slip) into molds | Manually shaping clay using hands and simple tools |

| Detail Precision | High - consistent shapes | Variable - depends on skill |

| Production Volume | Ideal for mass production | Best for unique, small batches |

| Time Efficiency | Faster for repeated forms | Slower, requires drying and refining |

| Skill Level | Moderate - mold preparation essential | High - artistic and manual expertise |

| Material Waste | Low - reuse of slip possible | Moderate - trimming and adjustments |

| Surface Texture | Smooth, uniform finish | Varied textures and organic forms |

| Typical Uses | Commercial ceramics, tableware | Artisanal pottery, sculptural pieces |

Introduction to Ceramic Slip Casting and Hand Building

Ceramic slip casting involves pouring liquid clay slip into plaster molds to create precise, uniform shapes with fine surface details. Hand building uses techniques like pinching, coiling, and slab construction to shape clay manually, allowing for more organic and unique forms. Slip casting excels in producing multiples with consistency, while hand building emphasizes artistic expression and individual craftsmanship.

Key Differences Between Slip Casting and Hand Building

Slip casting involves pouring liquid clay slip into plaster molds to create precise, uniform shapes, making it ideal for mass production of detailed ceramic forms. Hand building utilizes methods like pinching, coiling, and slab construction, allowing for more artistic freedom and unique, one-of-a-kind pieces with varied textures. Slip casting offers consistency and scalability, while hand building emphasizes individual craftsmanship and versatility in design.

Advantages of Slip Casting in Ceramics

Slip casting offers precise replication of intricate ceramic designs through the use of liquid clay poured into molds, enabling high consistency and efficient mass production. This technique reduces material waste and allows for thin, uniform walls that are difficult to achieve with hand building methods. The automation potential in slip casting accelerates the manufacturing process, making it ideal for commercial ceramic production.

Benefits of Hand Building Techniques

Hand building techniques in ceramics offer exceptional flexibility for creating unique, intricate shapes that are difficult to achieve with slip casting. This method allows artists to directly manipulate clay, enhancing texture and personal expression while reducing reliance on molds and equipment. The process supports sustainable practices by minimizing waste and encouraging the use of recycled or locally sourced materials.

Materials and Tools Required for Each Method

Ceramic slip casting requires liquid clay slip, plaster molds, a mixing container, and a casting vessel to shape consistent and detailed forms. Hand building utilizes solid clay blocks or slabs, basic tools such as wire cutters, ribs, and modeling tools to manually shape and assemble pieces. Slip casting demands precision in material preparation and mold handling, while hand building offers flexibility with tactile shaping using simpler, more varied tools.

Design Flexibility: Slip Casting vs Hand Building

Slip casting offers precise replication of complex shapes through molds, enabling consistent production of intricate ceramic forms, while hand building provides greater freedom for unique, organic designs and spontaneous creativity. The mold-dependent nature of slip casting limits customization to the mold's design, whereas hand building allows for continuous modification and adaptation during the creation process. Artists seeking mass production favor slip casting for uniformity, whereas those prioritizing artistic expression often prefer hand building for its design flexibility.

Production Speed and Scalability Comparison

Ceramic slip casting offers faster production speeds by allowing liquid clay to be poured into molds for consistent and rapid replication of complex shapes, making it ideal for large-scale manufacturing. Hand building relies on manual techniques such as pinching, coiling, and slab construction, which are time-consuming and limit scalability due to the artisanal level of craftsmanship required. Therefore, slip casting significantly enhances scalability and efficiency in ceramic production compared to the labor-intensive hand building method.

Surface Finishes and Artistic Detail

Ceramic slip casting produces smooth, uniform surface finishes ideal for detailed and consistent replication, while hand building allows for more textured, organic surfaces that reflect individual artistic expression. Slip casting is preferred for intricate, mass-produced items requiring fine detail retention, whereas hand building excels in unique, sculptural forms with varied textures. Surface quality in slip casting is typically more polished, whereas hand building showcases artistic nuances through visible tool marks and finger impressions.

Common Applications in Modern Ceramics

Ceramic slip casting is widely used in producing detailed and uniform shapes for mass production, such as sanitary ware, decorative figurines, and tile components. Hand building remains popular for bespoke, artisanal creations including sculptural ceramics, pottery, and experimental forms where unique textures and organic shapes are desired. Both techniques are fundamental in modern ceramics, with slip casting favored for efficiency and precision, and hand building for artistic expression and customization.

Choosing the Right Technique for Your Ceramic Project

Ceramic slip casting involves pouring liquid clay slip into molds, allowing for precise replication of complex shapes and consistent production, making it ideal for detailed or mass-produced pieces. Hand building offers greater creative freedom and tactile control, suitable for unique, organic forms or experimental designs where individual expression is paramount. Selecting the right technique depends on your project's complexity, desired finish, and production scale, balancing precision with artistic flexibility.

Ceramic Slip Casting vs Hand Building Infographic

materialdif.com

materialdif.com