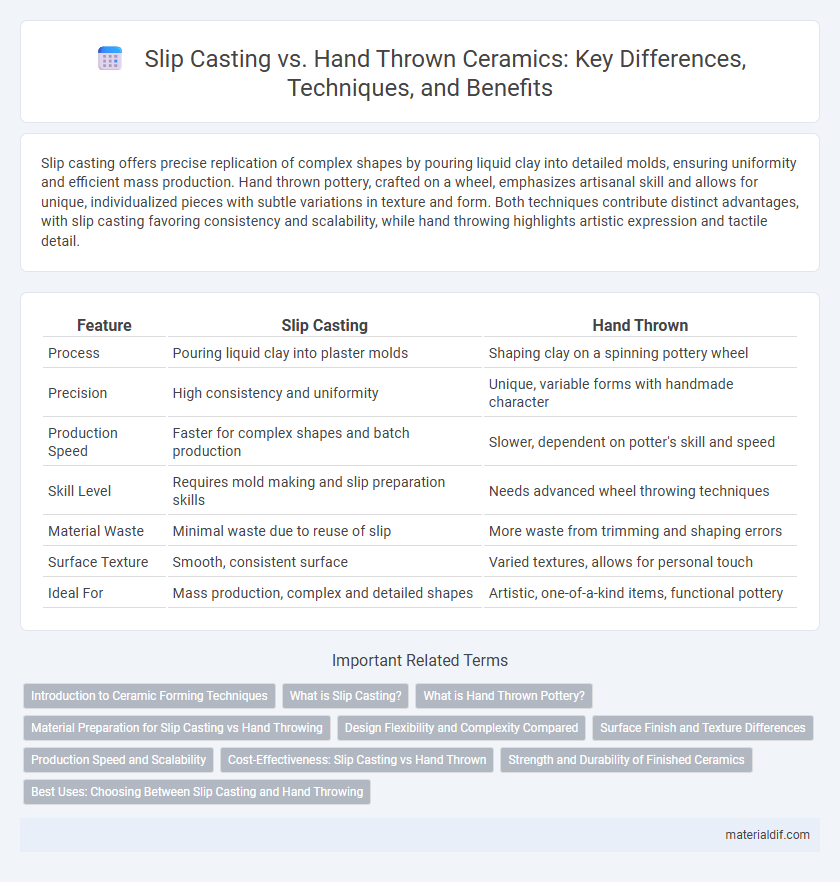

Slip casting offers precise replication of complex shapes by pouring liquid clay into detailed molds, ensuring uniformity and efficient mass production. Hand thrown pottery, crafted on a wheel, emphasizes artisanal skill and allows for unique, individualized pieces with subtle variations in texture and form. Both techniques contribute distinct advantages, with slip casting favoring consistency and scalability, while hand throwing highlights artistic expression and tactile detail.

Table of Comparison

| Feature | Slip Casting | Hand Thrown |

|---|---|---|

| Process | Pouring liquid clay into plaster molds | Shaping clay on a spinning pottery wheel |

| Precision | High consistency and uniformity | Unique, variable forms with handmade character |

| Production Speed | Faster for complex shapes and batch production | Slower, dependent on potter's skill and speed |

| Skill Level | Requires mold making and slip preparation skills | Needs advanced wheel throwing techniques |

| Material Waste | Minimal waste due to reuse of slip | More waste from trimming and shaping errors |

| Surface Texture | Smooth, consistent surface | Varied textures, allows for personal touch |

| Ideal For | Mass production, complex and detailed shapes | Artistic, one-of-a-kind items, functional pottery |

Introduction to Ceramic Forming Techniques

Slip casting utilizes liquid clay poured into plaster molds, enabling precise and uniform ceramic shapes, ideal for replicating complex designs with consistent thickness. Hand thrown ceramics involve shaping clay directly on a potter's wheel, allowing for unique, organic forms influenced by the potter's skill and technique. These forming methods represent foundational approaches in ceramic production, each offering distinct advantages in control, texture, and artistic expression.

What is Slip Casting?

Slip casting is a ceramic forming technique where liquid clay, known as slip, is poured into a plaster mold to create uniform and intricate shapes. This method allows for high precision and replication of detailed designs, unlike hand thrown pottery which relies on manual shaping on a wheel. Slip casting is ideal for producing complex forms and consistent batches in industrial and artistic ceramics.

What is Hand Thrown Pottery?

Hand thrown pottery refers to the traditional technique of shaping clay on a potter's wheel, allowing artisans to craft unique, symmetrical vessels through manual manipulation. This method emphasizes tactile control and artistic expression, resulting in diverse textures and forms that showcase the potter's skill and creativity. Unlike slip casting, hand thrown pottery involves direct interaction with the clay, producing one-of-a-kind pieces with subtle variations that highlight the handmade quality.

Material Preparation for Slip Casting vs Hand Throwing

Slip casting requires a finely processed, fluid clay slip prepared by mixing clay particles with water and deflocculants to achieve the ideal viscosity for mold pouring. Hand throwing involves using firm, plastic clay that is kneaded and wedged to remove air bubbles and ensure consistent texture for shaping on the wheel. Proper material preparation directly influences the structural integrity and surface finish in both ceramic techniques.

Design Flexibility and Complexity Compared

Slip casting allows for intricate, highly detailed ceramic forms to be produced consistently, making it ideal for complex designs and mass production. Hand thrown pottery offers greater spontaneity and organic variation, enabling artists to create unique, fluid shapes that are difficult to replicate by molds. Design flexibility in slip casting is limited by mold constraints, whereas hand throwing supports infinite shape variations driven by the potter's skill and creativity.

Surface Finish and Texture Differences

Slip casting produces smooth, uniform surfaces due to the liquid clay slip forming a consistent layer in the mold, making it ideal for detailed, delicate textures. Hand thrown ceramics exhibit more variability with tactile textures and slight imperfections from the potter's hands and wheel speed, offering a unique, organic finish. Surface finish in slip casting tends to be more polished and consistent, while hand thrown pieces reveal dynamic, natural grooves and textures.

Production Speed and Scalability

Slip casting offers significantly faster production speeds compared to hand thrown ceramics, enabling the creation of multiple uniform pieces simultaneously through molds. Scalability is more efficient with slip casting since it allows for consistent replication and high-volume output, ideal for commercial manufacturing. Hand thrown ceramics, while versatile and customizable, are limited by the slower, individual crafting process, making large-scale production less practical.

Cost-Effectiveness: Slip Casting vs Hand Thrown

Slip casting offers higher cost-effectiveness for mass production due to automated mold usage and reduced labor time, significantly lowering per-unit costs compared to hand throwing. Hand thrown ceramics require skilled artisans and longer production times, increasing labor costs but allowing for unique, bespoke designs. Choosing between these methods depends on balancing the need for scalable production versus artisanal quality and customization.

Strength and Durability of Finished Ceramics

Slip casting produces ceramics with uniform density and fewer air bubbles, resulting in enhanced strength and durability compared to hand-thrown pieces. Hand-thrown ceramics often have variable thicknesses and potential weaknesses due to uneven pressure application, which can reduce their structural integrity over time. The controlled molding process of slip casting ensures consistently stronger finished ceramics ideal for functional and decorative uses.

Best Uses: Choosing Between Slip Casting and Hand Throwing

Slip casting is ideal for producing detailed, uniform ceramic pieces in large quantities, making it perfect for mass production of intricate shapes and fine details. Hand throwing excels in creating unique, artisanal pottery with organic forms and subtle variations, suitable for custom and artistic works. Selecting between slip casting and hand throwing depends on the desired scale, consistency, and artistic expression of the ceramic project.

Slip Casting vs Hand Thrown Infographic

materialdif.com

materialdif.com