Dense body ceramics feature a compact microstructure with minimal pores, resulting in higher strength, durability, and resistance to moisture absorption. Porous body ceramics contain interconnected pores, which enhance thermal insulation and reduce weight but may compromise mechanical strength and increase susceptibility to damage. Choosing between dense and porous ceramic bodies depends on the specific requirements for performance, moisture resistance, and weight in pet applications.

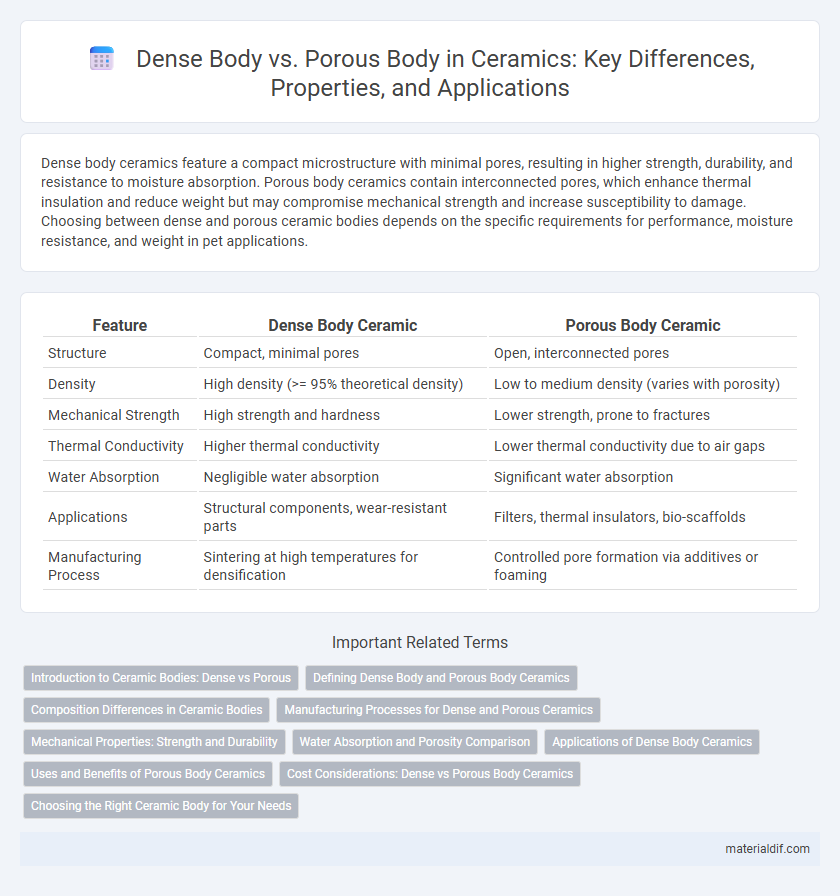

Table of Comparison

| Feature | Dense Body Ceramic | Porous Body Ceramic |

|---|---|---|

| Structure | Compact, minimal pores | Open, interconnected pores |

| Density | High density (>= 95% theoretical density) | Low to medium density (varies with porosity) |

| Mechanical Strength | High strength and hardness | Lower strength, prone to fractures |

| Thermal Conductivity | Higher thermal conductivity | Lower thermal conductivity due to air gaps |

| Water Absorption | Negligible water absorption | Significant water absorption |

| Applications | Structural components, wear-resistant parts | Filters, thermal insulators, bio-scaffolds |

| Manufacturing Process | Sintering at high temperatures for densification | Controlled pore formation via additives or foaming |

Introduction to Ceramic Bodies: Dense vs Porous

Dense ceramic bodies exhibit low porosity, resulting in high strength, durability, and resistance to moisture and chemical infiltration, making them ideal for structural and functional applications. Porous ceramic bodies possess interconnected pores that enhance insulation, filtration, and lightweight properties but reduce mechanical strength. Selecting between dense and porous ceramics depends on balancing factors such as thermal resistance, mechanical performance, and permeability requirements in various industrial and technological uses.

Defining Dense Body and Porous Body Ceramics

Dense body ceramics are characterized by a tightly packed microstructure with minimal porosity, resulting in high mechanical strength, low permeability, and enhanced durability. Porous body ceramics contain interconnected pores that reduce density, improve thermal insulation, and facilitate fluid or gas filtration. Understanding the distinctions between dense and porous ceramics is crucial for selecting appropriate materials in applications such as structural components or filtration systems.

Composition Differences in Ceramic Bodies

Dense ceramic bodies typically consist of finely ground raw materials such as kaolin, feldspar, and quartz, with minimal pore-forming agents, resulting in a compact microstructure and high mechanical strength. Porous ceramic bodies incorporate higher amounts of pore formers like organic materials, sawdust, or hollow spheres combined with coarser particles to create interconnected voids that enhance permeability and reduce density. The fundamental composition differences influence their thermal insulation properties, mechanical durability, and suitability for applications ranging from structural tiles to filtration media.

Manufacturing Processes for Dense and Porous Ceramics

Dense ceramics are manufactured using processes such as hot pressing, sintering, and isostatic pressing, which promote particle bonding and minimize porosity for high strength and durability. Porous ceramics are typically produced through methods like partial sintering, sacrificial templating, and freeze casting, allowing controlled pore formation for applications requiring filtration or insulation. Advanced techniques like additive manufacturing enable precise control over porosity and microstructure, optimizing performance based on specific functional requirements.

Mechanical Properties: Strength and Durability

Dense ceramic bodies exhibit higher mechanical strength and improved durability due to their tightly packed microstructure, which minimizes crack initiation and propagation. Porous ceramic bodies, while lighter and more thermally insulating, typically show reduced strength and are more susceptible to fracture under mechanical stress. The presence of pores acts as stress concentrators, significantly impacting the material's load-bearing capacity and long-term performance in structural applications.

Water Absorption and Porosity Comparison

Dense ceramic bodies exhibit significantly lower water absorption rates, typically below 0.5%, due to their minimal porosity, usually less than 1%. Porous ceramic bodies have higher water absorption, often exceeding 5%, reflecting increased porosity levels that allow more liquid infiltration. This difference directly impacts durability and application, with dense bodies preferred for structural uses and porous bodies favored in filtration or insulation contexts.

Applications of Dense Body Ceramics

Dense body ceramics offer superior mechanical strength, wear resistance, and chemical stability, making them ideal for cutting tools, biomedical implants, and electronic substrates. Their low porosity enhances thermal conductivity and corrosion resistance, crucial for high-performance engine components and industrial machinery. These properties enable dense body ceramics to perform reliably under extreme operational conditions where porous ceramics typically fail.

Uses and Benefits of Porous Body Ceramics

Porous body ceramics are highly valued for their exceptional filtration capabilities and thermal insulation properties, making them ideal for applications in water purification, gas filtration, and catalyst supports. Their interconnected pore structure allows for efficient fluid flow and lightweight performance while maintaining substantial mechanical strength. These ceramics also provide excellent sound absorption and temperature regulation, benefiting industries such as aerospace, automotive, and environmental technology.

Cost Considerations: Dense vs Porous Body Ceramics

Dense body ceramics demand higher production costs due to longer firing times and more refined raw materials, resulting in increased energy consumption and equipment wear. Porous body ceramics benefit from lower material expenses and shorter sintering cycles, reducing overall manufacturing costs. Selecting between dense and porous ceramics hinges on balancing budget constraints with desired mechanical strength and application requirements.

Choosing the Right Ceramic Body for Your Needs

Dense ceramic bodies offer superior strength, durability, and water resistance, making them ideal for functional tableware and industrial applications. Porous ceramic bodies provide better insulation and absorbency, suitable for decorative pieces and specialized uses requiring breathability. Selecting the right ceramic body depends on balancing mechanical properties and aesthetic requirements to fit your specific project needs.

Dense Body vs Porous Body Infographic

materialdif.com

materialdif.com