Sagger firing offers precise temperature control and protects ceramics from direct flame and ash, resulting in smoother surfaces and fewer defects. Open firing exposes ceramics directly to fire and smoke, producing unique textures and natural ash glazes but increases the risk of warping and cracks. Choosing between sagger and open firing depends on the desired aesthetic and durability of the final ceramic piece.

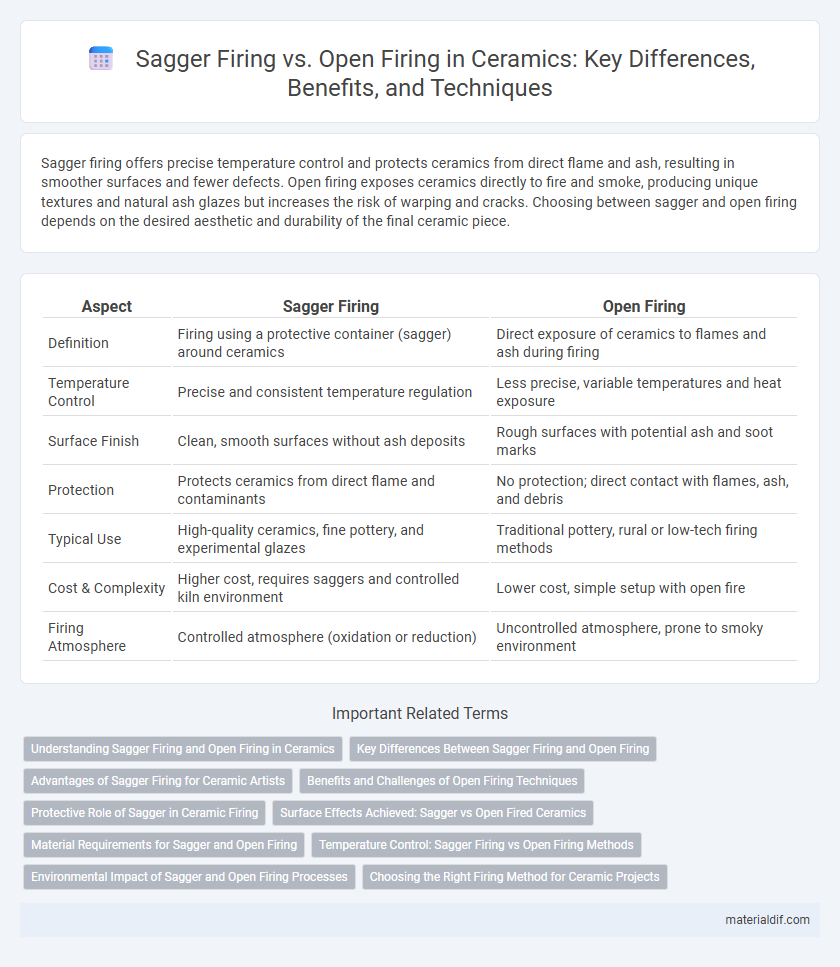

Table of Comparison

| Aspect | Sagger Firing | Open Firing |

|---|---|---|

| Definition | Firing using a protective container (sagger) around ceramics | Direct exposure of ceramics to flames and ash during firing |

| Temperature Control | Precise and consistent temperature regulation | Less precise, variable temperatures and heat exposure |

| Surface Finish | Clean, smooth surfaces without ash deposits | Rough surfaces with potential ash and soot marks |

| Protection | Protects ceramics from direct flame and contaminants | No protection; direct contact with flames, ash, and debris |

| Typical Use | High-quality ceramics, fine pottery, and experimental glazes | Traditional pottery, rural or low-tech firing methods |

| Cost & Complexity | Higher cost, requires saggers and controlled kiln environment | Lower cost, simple setup with open fire |

| Firing Atmosphere | Controlled atmosphere (oxidation or reduction) | Uncontrolled atmosphere, prone to smoky environment |

Understanding Sagger Firing and Open Firing in Ceramics

Sagger firing involves placing ceramics inside a protective container, or sagger, which shields the pieces from direct flame and ash, ensuring controlled atmospheric conditions and reducing surface contamination. Open firing exposes ceramics directly to heat and flames in an open environment, often resulting in unpredictable effects and unique surface textures due to varying temperatures and smoke interaction. Understanding these methods allows ceramic artists to control the final appearance, durability, and glaze effects by choosing between protective containment or natural exposure during firing.

Key Differences Between Sagger Firing and Open Firing

Sagger firing involves placing ceramics inside a protective container, or sagger, to shield them from direct flame and ash, resulting in controlled atmospheres and reduced surface damage. Open firing exposes ceramics directly to flames and smoke, often producing unpredictable effects and surface markings due to direct contact with combustion elements. Key differences include temperature control, atmosphere influence, and the level of ceramic surface protection during the firing process.

Advantages of Sagger Firing for Ceramic Artists

Sagger firing offers ceramic artists superior protection from direct flame and ash, resulting in cleaner, more controlled surface finishes and intricate glaze effects. This method enhances the preservation of delicate details and minimizes defects such as warping or scorching, which are common in open firing. The controlled atmosphere within the sagger allows for experimentation with unique textures and color variations, elevating the artistic quality of ceramic pieces.

Benefits and Challenges of Open Firing Techniques

Open firing in ceramics offers benefits such as enhanced surface textures and unique glazing effects that are difficult to replicate in controlled environments, making each piece truly distinctive. Challenges include uneven heat distribution and a higher risk of warping or cracking due to exposure to fluctuating temperatures and direct flames. Despite these issues, open firing remains valued for its cost-effectiveness and traditional aesthetic appeal.

Protective Role of Sagger in Ceramic Firing

Sagger firing uses a protective container, or sagger, made from refractory materials to shield ceramics from direct flame, ash, and kiln debris, ensuring a cleaner and more controlled firing environment. This protective barrier prevents contamination and uneven heat exposure, resulting in higher-quality, more uniform ceramic pieces with fewer defects. Open firing exposes ceramics directly to fire and elements, increasing the risk of surface damage, discoloration, and structural weaknesses compared to the sagger firing method.

Surface Effects Achieved: Sagger vs Open Fired Ceramics

Sagger firing produces ceramics with smoother, more uniform surface textures and rich, controlled coloration due to the protective atmosphere within the sagger, preventing ash and flame contact. Open firing exposes ceramics directly to flames and ash, resulting in unpredictable surface effects such as smoky patterns, rough textures, and natural ash glazes. The controlled environment of sagger firing offers refined surface finishes, while open firing embraces organic, rustic aesthetics with unique variations.

Material Requirements for Sagger and Open Firing

Sagger firing requires high-quality, refractory materials like fireclay, alumina, or silicon carbide to create protective containers that shield ceramics from direct flame and ash contamination, ensuring controlled atmosphere and cleanliness. Open firing relies on combustible fuels such as wood, charcoal, or organic matter, with no protective enclosure, exposing ceramics directly to flames and ash, which often demand the ceramics be made from more durable, heat-resistant clay bodies. The material demands in sagger firing emphasize heat retention and chemical stability, while open firing prioritizes the availability of fuel and the robustness of the ceramic material itself.

Temperature Control: Sagger Firing vs Open Firing Methods

Sagger firing offers precise temperature control by enclosing ceramics within protective containers that regulate heat exposure, ensuring consistent firing results and reducing the risk of oxidation or contamination. Open firing exposes wares directly to flames and atmospheric elements, resulting in fluctuating temperatures that can cause uneven firing and surface variations. The ability to maintain stable temperatures in sagger firing enhances glaze development and structural integrity compared to the unpredictable conditions of open firing methods.

Environmental Impact of Sagger and Open Firing Processes

Sagger firing significantly reduces environmental pollution by containing emissions within the sagger, minimizing the release of harmful gases and particulate matter. Open firing releases more pollutants directly into the atmosphere due to the uncontained burning process, contributing to air quality degradation and increased carbon emissions. The controlled environment of sagger firing enhances fuel efficiency, lowering overall energy consumption compared to the open firing method.

Choosing the Right Firing Method for Ceramic Projects

Sagger firing offers superior protection from direct flame and ash, resulting in enhanced surface quality and controlled atmospheres ideal for delicate ceramics. Open firing exposes pieces to unpredictable elements, often creating unique textures but increasing the risk of warping or damage. Assess project goals, desired finish, and kiln availability to select the firing method that best aligns with the ceramic work's structural and aesthetic requirements.

Sagger Firing vs Open Firing Infographic

materialdif.com

materialdif.com