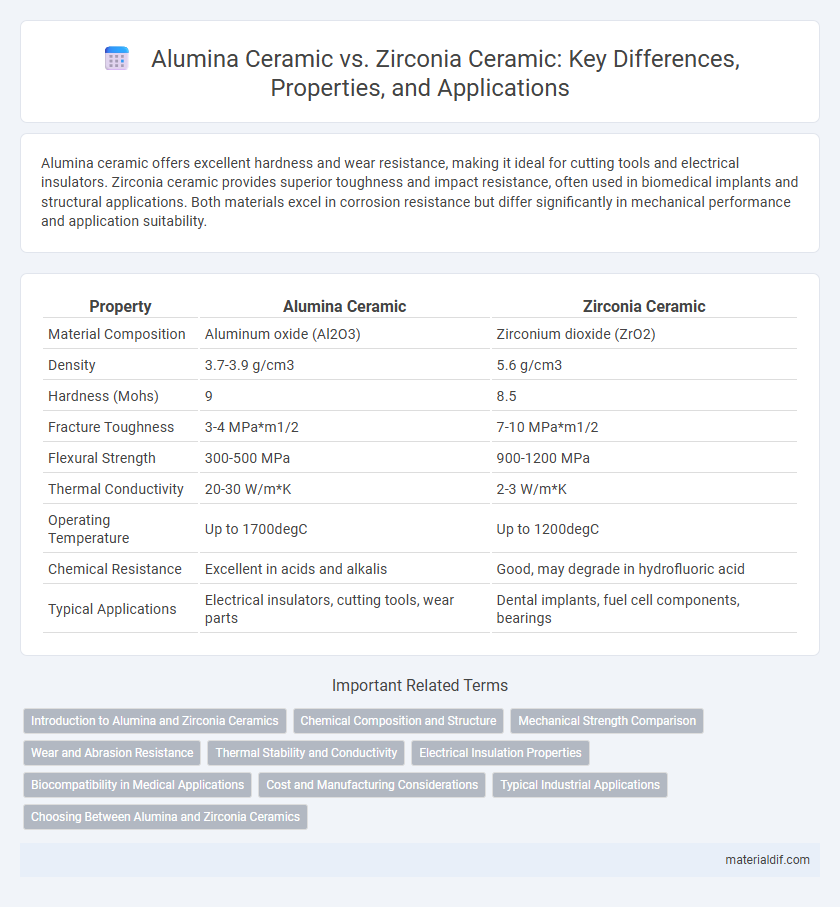

Alumina ceramic offers excellent hardness and wear resistance, making it ideal for cutting tools and electrical insulators. Zirconia ceramic provides superior toughness and impact resistance, often used in biomedical implants and structural applications. Both materials excel in corrosion resistance but differ significantly in mechanical performance and application suitability.

Table of Comparison

| Property | Alumina Ceramic | Zirconia Ceramic |

|---|---|---|

| Material Composition | Aluminum oxide (Al2O3) | Zirconium dioxide (ZrO2) |

| Density | 3.7-3.9 g/cm3 | 5.6 g/cm3 |

| Hardness (Mohs) | 9 | 8.5 |

| Fracture Toughness | 3-4 MPa*m1/2 | 7-10 MPa*m1/2 |

| Flexural Strength | 300-500 MPa | 900-1200 MPa |

| Thermal Conductivity | 20-30 W/m*K | 2-3 W/m*K |

| Operating Temperature | Up to 1700degC | Up to 1200degC |

| Chemical Resistance | Excellent in acids and alkalis | Good, may degrade in hydrofluoric acid |

| Typical Applications | Electrical insulators, cutting tools, wear parts | Dental implants, fuel cell components, bearings |

Introduction to Alumina and Zirconia Ceramics

Alumina ceramic, composed primarily of aluminum oxide (Al2O3), is renowned for its high hardness, excellent wear resistance, and thermal stability, making it ideal for cutting tools, electrical insulators, and biomedical implants. Zirconia ceramic, made from zirconium dioxide (ZrO2), offers superior toughness, fracture resistance, and biocompatibility, often used in dental restorations, fuel cells, and aerospace components. Both ceramics exhibit exceptional mechanical properties, but their distinct microstructures and phase compositions influence their performance in specific industrial and medical applications.

Chemical Composition and Structure

Alumina ceramic consists primarily of aluminum oxide (Al2O3) with a corundum crystal structure, providing high hardness and excellent chemical stability. Zirconia ceramic is made from zirconium dioxide (ZrO2), often stabilized with yttria, featuring a tetragonal crystal structure that offers superior toughness and fracture resistance. The distinct chemical compositions and crystalline arrangements directly influence their mechanical properties and corrosion resistance in various industrial applications.

Mechanical Strength Comparison

Alumina ceramic exhibits high hardness and excellent wear resistance, making it a preferred choice for applications requiring rigidity and durability under compressive loads. Zirconia ceramic surpasses alumina in mechanical strength due to its superior fracture toughness and higher flexural strength, which allows it to absorb impact and resist crack propagation more effectively. The transformation toughening mechanism in zirconia enhances its reliability in dynamic and high-stress environments compared to alumina's more brittle nature.

Wear and Abrasion Resistance

Alumina ceramic exhibits superior wear and abrasion resistance due to its high hardness and chemical stability, making it ideal for applications involving heavy mechanical stress. Zirconia ceramic, while slightly less hard, offers enhanced toughness and impact resistance, which contributes to prolonged durability under fluctuating loads and thermal cycling. Selecting between alumina and zirconia ceramics depends on the specific wear conditions and mechanical demands of the application.

Thermal Stability and Conductivity

Alumina ceramic exhibits superior thermal stability with a melting point around 2072degC and maintains structural integrity under high-temperature conditions, making it highly resistant to thermal shock. Zirconia ceramic offers lower thermal conductivity, approximately 2 W/m*K compared to alumina's 30 W/m*K, which provides better insulation properties but reduced heat dissipation. The choice between alumina and zirconia ceramics depends on application-specific thermal management requirements, balancing stability and conductivity.

Electrical Insulation Properties

Alumina ceramic exhibits superior electrical insulation properties with a high dielectric strength of approximately 10-15 kV/mm, making it ideal for electrical and electronic applications. Zirconia ceramic, while possessing moderate electrical insulation, offers enhanced toughness but typically lower dielectric strength, around 2-8 kV/mm. The choice between alumina and zirconia ceramics depends on balancing electrical insulation requirements with mechanical durability in specific industrial applications.

Biocompatibility in Medical Applications

Alumina ceramic exhibits excellent biocompatibility with low cytotoxicity and high wear resistance, making it suitable for orthopedic implants such as hip replacements. Zirconia ceramic offers superior mechanical strength and fracture toughness, combined with excellent biocompatibility, which enhances osseointegration in dental and bone implants. Both materials resist corrosion and reduce inflammation risks, but zirconia's higher bio-inertness often favors long-term implant success in medical applications.

Cost and Manufacturing Considerations

Alumina ceramic offers a lower cost advantage compared to zirconia ceramic due to its abundant raw materials and simpler manufacturing processes, making it suitable for high-volume productions. Zirconia ceramic involves more complex processing techniques and higher material costs driven by its superior toughness and fracture resistance. Manufacturing considerations also highlight that alumina's higher sintering temperatures and longer cycles can impact production efficiency, while zirconia's processing requires precise control of phase stabilization to maintain its mechanical properties.

Typical Industrial Applications

Alumina ceramic is widely used in electrical insulation, cutting tools, and wear-resistant components due to its excellent hardness and thermal conductivity. Zirconia ceramic is preferred in dental implants, fuel cell membranes, and high-performance bearings because of its superior fracture toughness and chemical stability. Both materials are critical in manufacturing industries where durability and precision are essential for industrial applications.

Choosing Between Alumina and Zirconia Ceramics

Alumina ceramic offers superior hardness and excellent wear resistance, making it ideal for cutting tools and electrical insulators, while zirconia ceramic excels in toughness and fracture resistance, often used in medical implants and dental restorations. Selecting between alumina and zirconia ceramics depends on the specific application requirements such as mechanical strength, thermal stability, and biocompatibility. Zirconia's higher fracture toughness is favored for impact-prone environments, whereas alumina's stability at high temperatures suits harsh industrial conditions.

Alumina Ceramic vs Zirconia Ceramic Infographic

materialdif.com

materialdif.com