High-fire ceramics are fired at temperatures above 2300degF (1260degC), resulting in dense, durable, and vitrified pieces that are highly resistant to water and wear. Low-fire ceramics, fired between 1700degF and 2100degF (930degC to 1150degC), allow for brighter and more varied glaze colors but tend to be more porous and less durable. Choosing between high-fire and low-fire depends on the desired aesthetic, functionality, and final use of the ceramic piece.

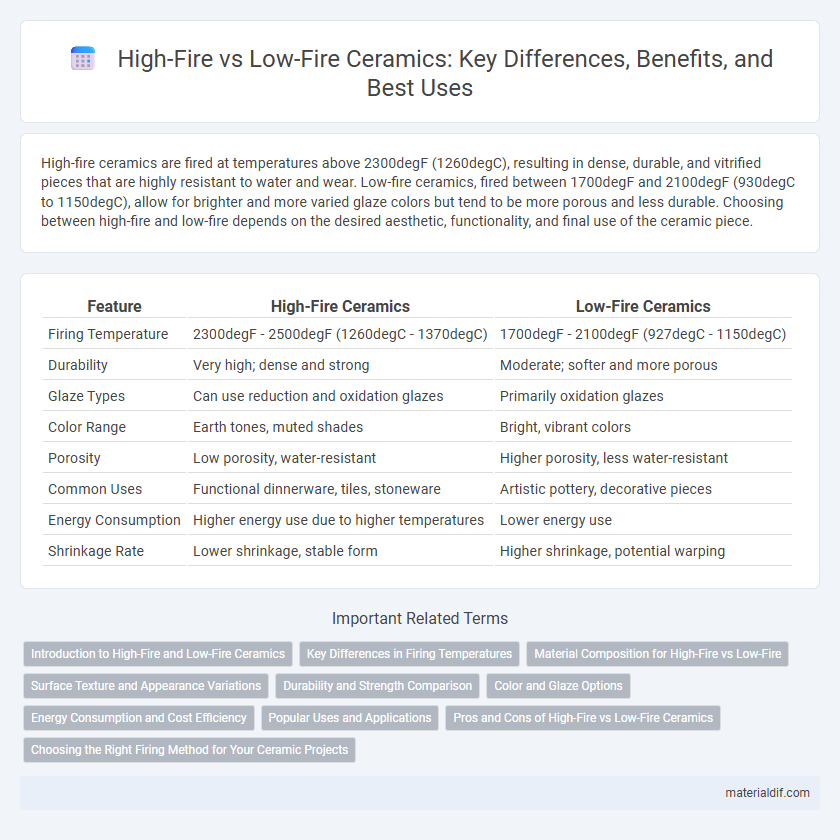

Table of Comparison

| Feature | High-Fire Ceramics | Low-Fire Ceramics |

|---|---|---|

| Firing Temperature | 2300degF - 2500degF (1260degC - 1370degC) | 1700degF - 2100degF (927degC - 1150degC) |

| Durability | Very high; dense and strong | Moderate; softer and more porous |

| Glaze Types | Can use reduction and oxidation glazes | Primarily oxidation glazes |

| Color Range | Earth tones, muted shades | Bright, vibrant colors |

| Porosity | Low porosity, water-resistant | Higher porosity, less water-resistant |

| Common Uses | Functional dinnerware, tiles, stoneware | Artistic pottery, decorative pieces |

| Energy Consumption | Higher energy use due to higher temperatures | Lower energy use |

| Shrinkage Rate | Lower shrinkage, stable form | Higher shrinkage, potential warping |

Introduction to High-Fire and Low-Fire Ceramics

High-fire ceramics are typically fired at temperatures ranging from 1,200degC to 1,400degC, resulting in durable, vitrified pottery with a dense, glass-like surface. Low-fire ceramics, fired between 1,000degC and 1,100degC, offer greater color vibrancy and more surface texture due to their lower melting point glazes. These differing firing ranges influence clay body maturity, glaze chemistry, and overall aesthetic qualities, making each suitable for specific artistic and functional applications.

Key Differences in Firing Temperatures

High-fire ceramics are typically fired at temperatures ranging from 2300degF to 2500degF (1260degC to 1370degC), resulting in denser, more vitrified surfaces with greater durability and reduced porosity. Low-fire ceramics are fired between 1828degF and 2167degF (998degC to 1186degC), producing softer, more porous pieces that allow for brighter glaze colors due to lower temperature constraints. These firing temperature differences significantly impact the material properties, glaze behavior, and final aesthetic qualities of ceramic ware.

Material Composition for High-Fire vs Low-Fire

High-fire ceramics utilize clays with high alumina and silica content, which withstand temperatures above 2300degF (1260degC) without melting or deforming. Low-fire ceramics rely on clays with lower alumina and silica content, often incorporating fluxes like feldspar to mature at temperatures between 1828degF and 2167degF (998degC to 1186degC). The differing mineral compositions affect vitrification, porosity, and glaze compatibility, with high-fire materials producing more durable results and low-fire clays allowing brighter glaze colors.

Surface Texture and Appearance Variations

High-fire ceramics, fired at temperatures above 2300degF (1260degC), develop dense, vitrified surfaces with muted, earthy tones and subtle glaze variations, offering a smooth, often matte texture. Low-fire ceramics, typically fired below 2100degF (1150degC), showcase brighter, more vibrant colors and a wider range of glaze effects, resulting in varied textures from glossy to slightly porous surfaces. Surface texture and appearance in high-fire versus low-fire ceramics are distinct due to differing firing temperatures, clay body maturation, and glaze chemistry interactions.

Durability and Strength Comparison

High-fire ceramics, fired at temperatures above 2300degF (1260degC), exhibit superior durability and strength due to vitrification, resulting in a denser, less porous surface resistant to chipping and thermal shock. Low-fire ceramics, fired between 1800degF and 2100degF (982degC to 1149degC), feature brighter glaze colors but tend to be more porous and fragile, making them less suitable for functional ware requiring high strength. The enhanced durability of high-fire ceramics makes them ideal for heavy-use dinnerware and architectural applications where mechanical stress and moisture resistance are critical.

Color and Glaze Options

High-fire ceramics reach temperatures above 2300degF, resulting in durable, vitrified surfaces with rich, earthy glaze colors such as deep blues, browns, and reds, favored for stoneware and porcelain. Low-fire ceramics mature below 2100degF, allowing for a wider palette of vibrant and bright glaze colors, including reds, pinks, and yellows, due to less glaze melting and color burnout. Choosing between high-fire and low-fire techniques depends on the desired durability and specific color and glaze effects required for the ceramic piece.

Energy Consumption and Cost Efficiency

High-fire ceramics require temperatures above 2300degF, leading to significantly higher energy consumption compared to low-fire ceramics, which mature at temperatures between 1828degF and 2100degF. The increased energy demand for high-fire processes results in higher operational costs, making low-fire techniques more cost-efficient for studios and manufacturers. Low-fire ceramics also allow faster firing cycles, reducing fuel usage and overall production expenses without compromising glaze variety and durability.

Popular Uses and Applications

High-fire ceramics, fired at temperatures above 2300degF (1260degC), are favored for their durability and resistance to thermal shock, making them ideal for functional ware like kitchenware, tiles, and architectural ceramics. Low-fire ceramics, fired between 1828degF and 2012degF (998degC to 1100degC), are popular in artistic applications such as decorative pottery, sculpture, and glazed earthenware due to their vibrant glaze colors and faster firing process. The choice between high-fire and low-fire techniques depends on the desired strength, finish, and aesthetic qualities of the ceramic product.

Pros and Cons of High-Fire vs Low-Fire Ceramics

High-fire ceramics, fired at temperatures between 2300degF and 2500degF, offer superior durability, resistance to chipping, and enhanced vitrification, making them ideal for functional pottery and dinnerware. Low-fire ceramics, typically fired between 1828degF and 2100degF, allow for a broader palette of vibrant glazes and faster firing cycles but tend to be more porous and less durable, suitable for decorative pieces. While high-fire ceramics provide long-lasting strength, they require longer firing times and higher energy consumption compared to the more versatile and quicker low-fire options.

Choosing the Right Firing Method for Your Ceramic Projects

High-fire ceramics are fired between 2300degF and 2500degF, resulting in denser, more durable pieces with vitrified surfaces ideal for functional pottery. Low-fire ceramics, typically fired between 1800degF and 2100degF, allow for brighter glazes and intricate surface decorations but produce more porous, less durable results. Selecting the right firing method depends on the desired durability, glaze effects, and the intended use of the ceramic project.

High-Fire vs Low-Fire Infographic

materialdif.com

materialdif.com