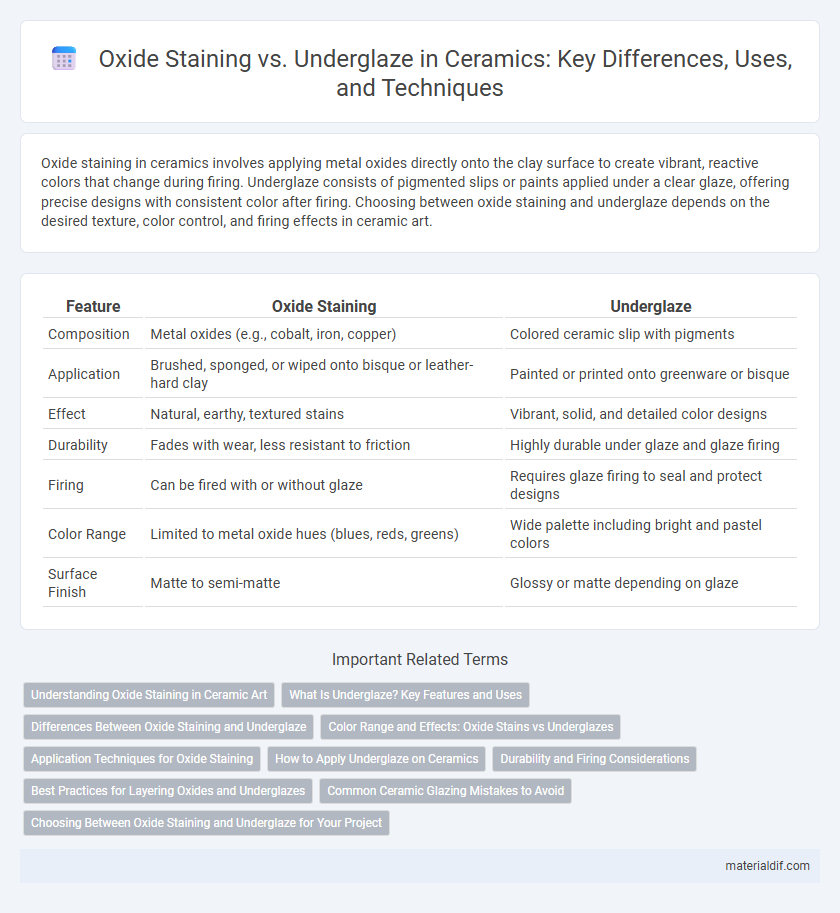

Oxide staining in ceramics involves applying metal oxides directly onto the clay surface to create vibrant, reactive colors that change during firing. Underglaze consists of pigmented slips or paints applied under a clear glaze, offering precise designs with consistent color after firing. Choosing between oxide staining and underglaze depends on the desired texture, color control, and firing effects in ceramic art.

Table of Comparison

| Feature | Oxide Staining | Underglaze |

|---|---|---|

| Composition | Metal oxides (e.g., cobalt, iron, copper) | Colored ceramic slip with pigments |

| Application | Brushed, sponged, or wiped onto bisque or leather-hard clay | Painted or printed onto greenware or bisque |

| Effect | Natural, earthy, textured stains | Vibrant, solid, and detailed color designs |

| Durability | Fades with wear, less resistant to friction | Highly durable under glaze and glaze firing |

| Firing | Can be fired with or without glaze | Requires glaze firing to seal and protect designs |

| Color Range | Limited to metal oxide hues (blues, reds, greens) | Wide palette including bright and pastel colors |

| Surface Finish | Matte to semi-matte | Glossy or matte depending on glaze |

Understanding Oxide Staining in Ceramic Art

Oxide staining in ceramic art involves applying metal oxides, such as iron, cobalt, or copper, to clay surfaces, resulting in rich, varied colors after firing. Unlike underglaze, which is a pigmented slip applied under a transparent glaze, oxide stains chemically interact with the clay body, creating unique textures and color effects that are less uniform but highly expressive. Mastering oxide staining requires understanding the firing temperature and clay composition, as these factors significantly influence the final appearance and permanence of the stain.

What Is Underglaze? Key Features and Uses

Underglaze is a ceramic decoration technique involving colored pigments applied to pottery before glazing, creating detailed, durable designs beneath a transparent glaze layer. Key features include high color stability during firing, versatility in design complexity, and compatibility with various clay bodies. It is commonly used for intricate patterns, fine lines, and multicolor effects on functional and decorative ceramics.

Differences Between Oxide Staining and Underglaze

Oxide staining uses metal oxides like iron or cobalt applied directly to ceramic surfaces to create translucent, varied color effects that develop during firing, emphasizing texture and natural variations. Underglaze consists of colored pigments mixed with a medium, providing consistent, opaque designs that remain stable under a clear glaze and are less affected by firing conditions. The key difference lies in oxide staining's reactive, organic finish versus underglaze's precise, uniform color application.

Color Range and Effects: Oxide Stains vs Underglazes

Oxide stains offer a limited yet earthy color range, producing subtle and natural effects on ceramic surfaces, often emphasizing texture and tonal variations. Underglazes provide a broader spectrum of vibrant and consistent colors, allowing for detailed patterns and smoother finishes beneath clear glazes. The choice between oxide staining and underglaze depends on the desired visual outcome, with oxides enhancing raw, organic aesthetics and underglazes offering precise, colorful expressions.

Application Techniques for Oxide Staining

Oxide staining in ceramics involves applying metal oxides, such as cobalt, iron, or copper oxides, directly onto the clay surface or bisque-fired ware to create vibrant, textured effects. The staining technique requires careful manipulation with brushes, sponges, or dipping methods to achieve desired patterns and depth, often followed by a transparent glaze to seal the color and enhance durability. Unlike underglaze, oxide stains interact uniquely with the clay body and firing atmosphere, producing richer, more variable outcomes ideal for surface decoration and highlighting textures.

How to Apply Underglaze on Ceramics

Apply underglaze on ceramics by first cleaning the bisque-fired surface to ensure it is free of dust and oils, allowing the pigment to adhere properly. Use brushes, sponges, or stamping tools to apply the underglaze evenly, building up layers for depth and detail before firing. Underglaze offers vibrant, durable color that withstands high temperatures, unlike oxide stains that penetrate and create subtle, variegated effects.

Durability and Firing Considerations

Oxide staining offers strong durability due to its chemical stability during high-temperature firing, typically ranging from cone 06 to cone 10, making it resistant to fading and wear. Underglaze, applied beneath a transparent glaze, provides vibrant color options but may require precise firing schedules to prevent color shifts or glaze defects, especially in oxidation or reduction atmospheres. Both techniques demand careful temperature control, but oxide stains generally ensure longer-lasting color retention and surface resilience after multiple firings.

Best Practices for Layering Oxides and Underglazes

Layering oxides and underglazes requires careful control of application thickness and drying time to prevent unwanted blending or bleeding of colors on ceramic surfaces. Applying thin oxide washes before underglaze layers allows for subtle color interactions and enhances depth without compromising surface texture. It is essential to test firing temperatures and compatibility to maintain vibrancy and prevent chemical reactions that cause discoloration or surface defects.

Common Ceramic Glazing Mistakes to Avoid

Oxide staining often causes uneven color and blotchy surfaces due to improper application or firing temperature inconsistencies, leading to unpredictable results in ceramic glazing. Underglaze requires precise layering and drying times, as applying too thick or too thin a coat can result in cracking or dull finishes. Avoid these common mistakes by testing oxide stains on test tiles and controlling underglaze thickness to ensure vibrant, stable ceramic surfaces.

Choosing Between Oxide Staining and Underglaze for Your Project

Choosing between oxide staining and underglaze for your ceramic project depends on desired texture, color intensity, and firing temperature compatibility. Oxide staining offers organic, earthy tones that highlight surface texture, ideal for matte or rustic finishes, while underglazes provide vibrant, precise color and detailed designs suitable for glossy or smooth surfaces. Evaluate your kiln firing schedule and final aesthetic goals to determine the best option for durability and visual impact.

Oxide Staining vs Underglaze Infographic

materialdif.com

materialdif.com