High-fire ceramics are fired at temperatures above 2300degF (1260degC), resulting in dense, vitrified pieces that are durable and resistant to water and chemicals. Low-fire ceramics, fired at temperatures between 1700degF and 2100degF (927degC to 1150degC), tend to have brighter, more vibrant glazes but are typically more porous and less durable. The choice between high-fire and low-fire ceramics depends on the desired balance of strength, finish, and color vibrancy.

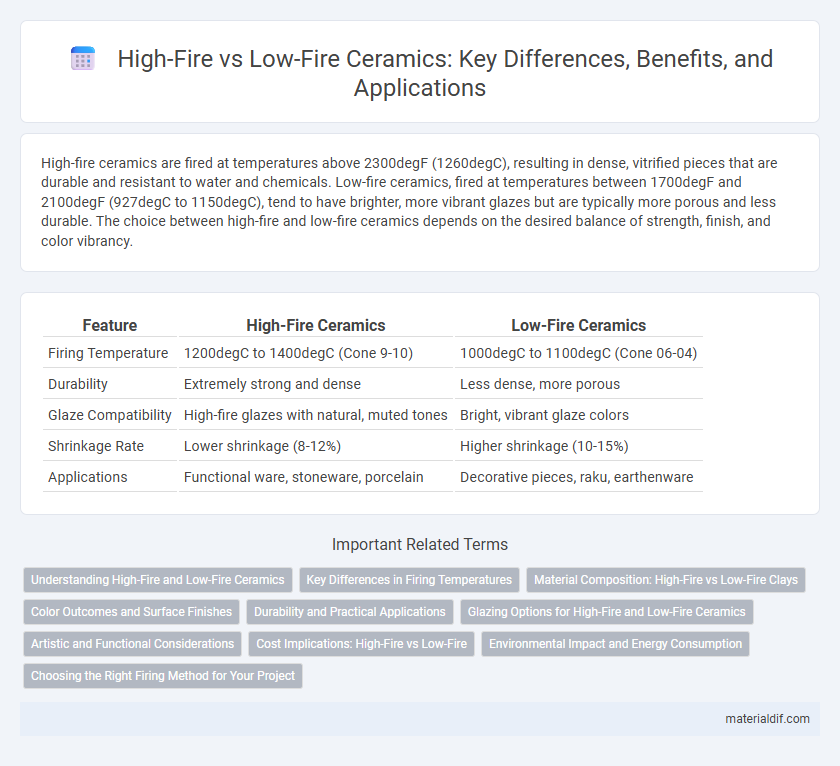

Table of Comparison

| Feature | High-Fire Ceramics | Low-Fire Ceramics |

|---|---|---|

| Firing Temperature | 1200degC to 1400degC (Cone 9-10) | 1000degC to 1100degC (Cone 06-04) |

| Durability | Extremely strong and dense | Less dense, more porous |

| Glaze Compatibility | High-fire glazes with natural, muted tones | Bright, vibrant glaze colors |

| Shrinkage Rate | Lower shrinkage (8-12%) | Higher shrinkage (10-15%) |

| Applications | Functional ware, stoneware, porcelain | Decorative pieces, raku, earthenware |

Understanding High-Fire and Low-Fire Ceramics

High-fire ceramics are fired at temperatures between 2,300degF and 2,500degF (1,260degC to 1,370degC), producing dense, vitrified, and highly durable pottery with reduced porosity. Low-fire ceramics are fired at lower temperatures, typically between 1,830degF and 2,100degF (1,000degC to 1,150degC), resulting in more porous and less durable pieces but allowing for a wider range of vibrant glazes. Understanding the thermal properties and effects on glaze compatibility is crucial when choosing between high-fire and low-fire ceramics for both artistic and functional purposes.

Key Differences in Firing Temperatures

High-fire ceramics are typically fired at temperatures above 2300degF (1260degC), resulting in denser, more durable, and vitrified pieces, while low-fire ceramics are fired at lower temperatures, usually between 1828degF and 2012degF (998degC to 1100degC), producing more porous and less durable goods. High-fire clay bodies often require kiln atmospheres that support reduction or oxidation, influencing glaze effects and surface textures, whereas low-fire bodies allow for a wider range of bright, vibrant glaze colors due to less fluxing of the glaze materials. The choice between high-fire and low-fire ceramics directly impacts the application, appearance, and strength of the final ceramic product.

Material Composition: High-Fire vs Low-Fire Clays

High-fire ceramics use clays with higher alumina and silica content, such as stoneware and porcelain, allowing them to withstand temperatures above 2300degF (1260degC). Low-fire ceramics typically contain soft clay bodies with higher flux content, like earthenware, which mature at temperatures below 2100degF (1150degC). The material composition directly influences the vitrification, durability, and porosity of the finished ceramic piece.

Color Outcomes and Surface Finishes

High-fire ceramics, fired at temperatures above 2300degF (1260degC), produce rich, deep colors with natural, muted tones and durable, glassy surface finishes that resist scratches and chemical damage. Low-fire ceramics, fired below 2100degF (1150degC), allow for brighter, more vibrant glazes with a wider color palette but tend to have softer, more porous surfaces that are less durable. The choice between high-fire and low-fire ceramics significantly impacts the aesthetic outcome and functional durability of the final piece.

Durability and Practical Applications

High-fire ceramics, fired at temperatures above 2,300degF (1,260degC), are renowned for their superior durability, density, and resistance to chipping and thermal shock, making them ideal for functional wares like cookware and industrial components. Low-fire ceramics, typically fired between 1,830degF to 2,100degF (1,000degC to 1,150degC), offer vibrant glaze possibilities but are more porous and less durable, suiting decorative pieces and items with less frequent use. Understanding the firing temperature's impact on porosity and strength helps artisans and manufacturers choose the right ceramic type for specific practical applications.

Glazing Options for High-Fire and Low-Fire Ceramics

High-fire ceramics, fired at temperatures above 2300degF (1260degC), typically feature glazes that are more durable, glossy, and fused into the body, resulting in enhanced resistance to scratches and chemicals. Low-fire ceramics, fired below 2100degF (1150degC), allow for a wider variety of vibrant, bright glaze colors due to lower firing temperatures but can be more porous and less durable without additional sealing. Both firing methods offer distinct glazing styles, with high-fire glazes excelling in strength and low-fire glazes providing greater creative flexibility in surface finishes.

Artistic and Functional Considerations

High-fire ceramics, fired at temperatures above 2300degF (1260degC), offer superior durability and a vitrified, glass-like surface that enhances both artistic detail and functional strength, making them ideal for utilitarian ware and outdoor sculptures. Low-fire ceramics, fired between 1830degF and 2100degF (999degC to 1150degC), allow for a broader color palette and finer surface textures, catering to intricate artistic expressions and decorative pieces but with reduced resistance to thermal shock and wear. Artists often select high-fire ceramics for functional items requiring resilience, while low-fire ceramics suit vibrant, delicate artworks where color complexity and surface finish are prioritized.

Cost Implications: High-Fire vs Low-Fire

High-fire ceramics require higher kiln temperatures, resulting in increased energy consumption and higher operational costs compared to low-fire ceramics, which mature at lower temperatures and reduce fuel expenses. The cost of raw materials also varies, with high-fire clays often being more durable but pricier, while low-fire clays are generally less expensive and more abundant. Maintenance costs for high-fire kilns tend to be greater due to the extreme heat and wear on kiln elements, whereas low-fire kilns experience less thermal stress, contributing to lower long-term expenses.

Environmental Impact and Energy Consumption

High-fire ceramics, fired at temperatures above 1200degC, require significantly more energy, leading to a larger carbon footprint compared to low-fire ceramics, which mature between 900degC and 1100degC. The increased kiln energy consumption for high-fire ceramics contributes to higher greenhouse gas emissions, impacting environmental sustainability. Low-fire ceramics, though less durable, offer a more eco-friendly option with reduced energy demands and lower environmental impact during production.

Choosing the Right Firing Method for Your Project

High-fire ceramics are fired between 2300degF and 2500degF, resulting in durable, vitrified pieces with a glass-like surface ideal for functional items like dinnerware and tiles. Low-fire ceramics, fired between 1800degF and 2100degF, offer vibrant glazes and faster firing times, making them suitable for decorative art and intricate designs. Selecting the right firing method depends on the desired durability, glaze finish, and project purpose, ensuring optimal results for both functional and aesthetic ceramic works.

High-Fire Ceramics vs Low-Fire Ceramics Infographic

materialdif.com

materialdif.com