Press molding offers precise control over the shape and thickness of ceramic pieces, making it ideal for producing intricate designs and consistent results. Jiggering is a faster, more cost-effective method suited for creating symmetrical, round ceramics, often used in mass production. Both techniques optimize ceramic manufacturing by balancing detail accuracy and production speed.

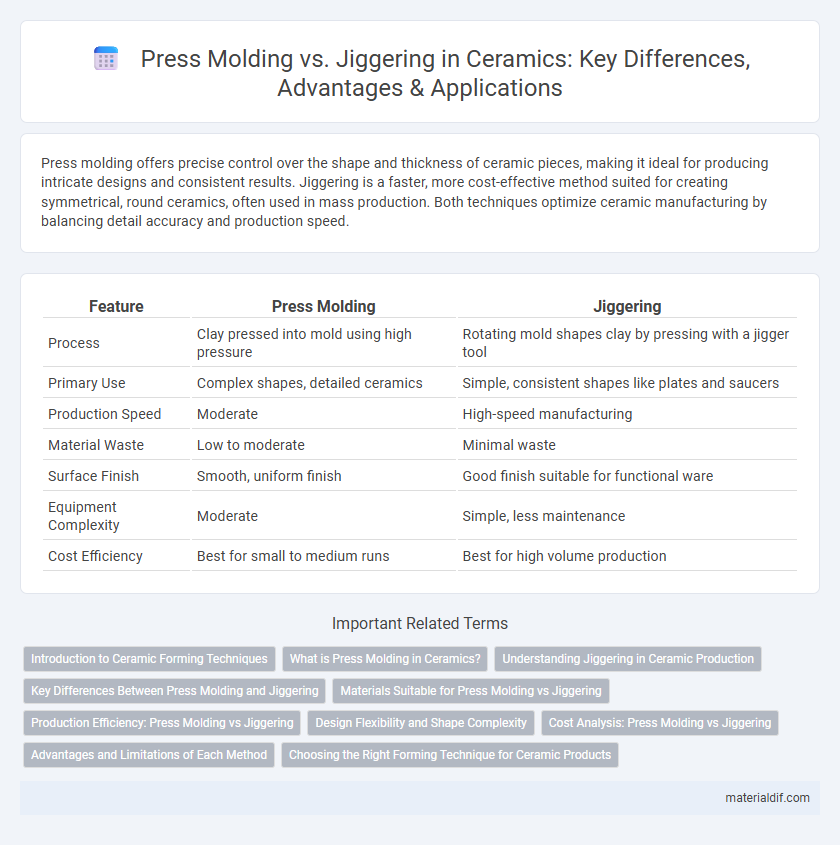

Table of Comparison

| Feature | Press Molding | Jiggering |

|---|---|---|

| Process | Clay pressed into mold using high pressure | Rotating mold shapes clay by pressing with a jigger tool |

| Primary Use | Complex shapes, detailed ceramics | Simple, consistent shapes like plates and saucers |

| Production Speed | Moderate | High-speed manufacturing |

| Material Waste | Low to moderate | Minimal waste |

| Surface Finish | Smooth, uniform finish | Good finish suitable for functional ware |

| Equipment Complexity | Moderate | Simple, less maintenance |

| Cost Efficiency | Best for small to medium runs | Best for high volume production |

Introduction to Ceramic Forming Techniques

Press molding in ceramics involves compressing powdered clay into a rigid mold to achieve precise shapes with high density and minimal porosity. Jiggering utilizes a rotating mold and a shaped tool to form flatware and hollow ware efficiently, offering consistent thickness and smooth surfaces. Both techniques provide essential methods for mass-producing ceramic products, with press molding excelling in detailed shapes and jiggering suited for symmetrical items.

What is Press Molding in Ceramics?

Press molding in ceramics is a manufacturing process where clay is shaped by applying pressure within a rigid mold, allowing for precise and consistent replication of complex forms. This technique is ideal for producing high volumes of uniform ceramic pieces with detailed surface textures and sharp edges. Press molding offers faster production cycles and reduces material waste compared to traditional hand-building methods.

Understanding Jiggering in Ceramic Production

Jiggering in ceramic production involves shaping clay on a rotating mold using a profile tool to form consistent and precise cylindrical wares like plates and bowls, optimizing uniformity and surface finish. This method contrasts with press molding, which uses pressure to shape clay in molds and is better suited for complex or textured designs. Understanding jiggering enhances production efficiency by enabling rapid, repeatable shapes ideal for high-volume manufacturing of functional ceramic tableware.

Key Differences Between Press Molding and Jiggering

Press molding involves shaping ceramic clay by applying pressure within a mold, producing precise and consistent forms, especially for complex geometries. Jiggering uses a rotating mold and a shaped profile tool to form flat or slightly curved ceramic wares, typically for plates and shallow bowls. The key differences lie in press molding's ability to achieve intricate designs with higher pressure versus jiggering's efficiency in mass-producing uniform flatware through rotational forming.

Materials Suitable for Press Molding vs Jiggering

Press molding is ideal for materials with high plasticity such as kaolin, ball clay, and porcelain, enabling precise shaping under pressure, while jiggering suits more robust and less plastic clays like stoneware and earthenware. The fine particle size and plastic properties of materials used in press molding allow for intricate details and smooth finishes, whereas jiggering accommodates thicker, more durable ceramic bodies designed for mass production. Selecting the appropriate technique depends on the clay's plasticity, particle size, and intended product strength.

Production Efficiency: Press Molding vs Jiggering

Press molding offers higher production efficiency for complex ceramic shapes by enabling precise, rapid forming with minimal material waste, especially suited for high-volume runs. Jiggering excels in producing consistent, rotationally symmetrical pieces such as tableware, providing faster cycle times and reduced labor costs due to its automated shaping process. Selection between the two depends on product design complexity and desired production scale, with press molding favoring intricate forms and jiggering optimizing throughput for simpler profiles.

Design Flexibility and Shape Complexity

Press molding offers superior design flexibility and can efficiently produce complex ceramic shapes with high precision, making it ideal for intricate patterns and detailed contours. Jiggering, while cost-effective for symmetrical and simpler forms like plates and bowls, is limited in accommodating highly complex shapes or asymmetrical designs. Selecting press molding enhances the ability to create customized ceramic products with varied geometries that jiggering methods cannot easily replicate.

Cost Analysis: Press Molding vs Jiggering

Press molding typically incurs higher initial equipment costs due to the precision hydraulic systems required, but offers lower labor expenses through automation, enhancing cost efficiency in large production runs. Jiggering involves lower startup costs with simpler machinery, making it more suitable for small-scale or artisanal ceramic production despite higher labor intensity. Cost analysis reveals press molding's scalability advantages offset significant capital investment, whereas jiggering remains economically viable for limited quantities and customized designs.

Advantages and Limitations of Each Method

Press molding offers precise control over complex shapes and consistent surface finishes, making it ideal for intricate ceramic parts and mass production with minimal material waste. Jiggering excels in forming symmetrical, round ceramic items such as plates and bowls rapidly, benefiting from high production speed and cost efficiency but limited to rotationally symmetric designs. While press molding accommodates diverse geometries, it requires higher tooling costs and longer setup times compared to the simpler, faster jiggering process that restricts design versatility.

Choosing the Right Forming Technique for Ceramic Products

Press molding offers precise control and high repeatability, making it ideal for intricate ceramic shapes and mass production with consistent quality. Jiggering excels in forming symmetrical, curved ceramic items such as plates and bowls, providing efficient shaping with less material waste. Selecting the right technique depends on product complexity, volume, and surface finish requirements to optimize manufacturing efficiency and final product performance.

Press Molding vs Jiggering Infographic

materialdif.com

materialdif.com