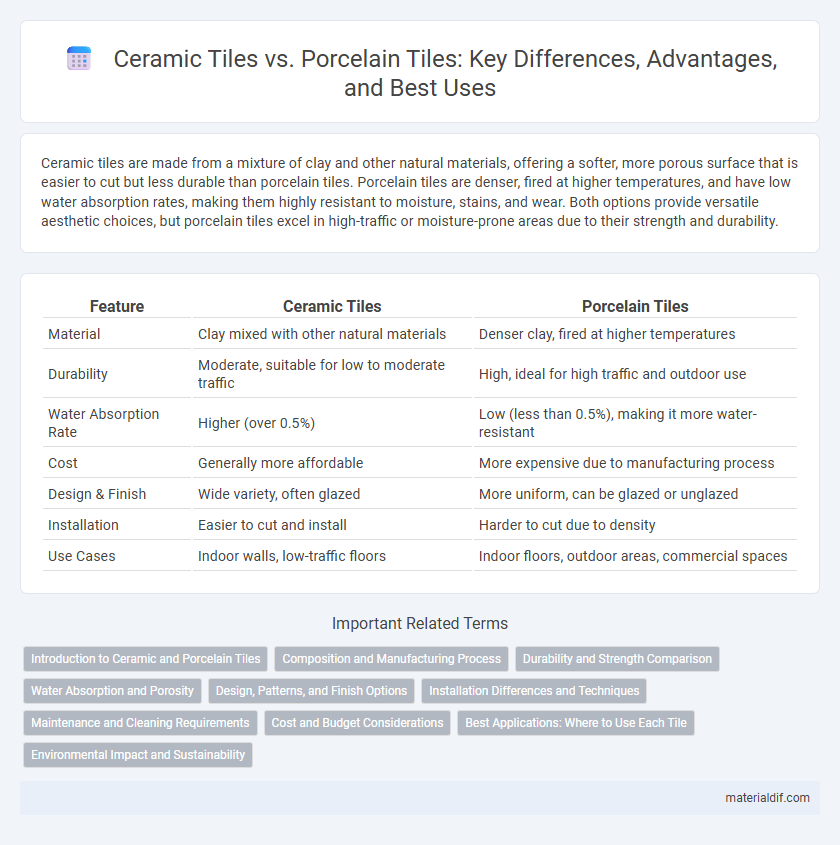

Ceramic tiles are made from a mixture of clay and other natural materials, offering a softer, more porous surface that is easier to cut but less durable than porcelain tiles. Porcelain tiles are denser, fired at higher temperatures, and have low water absorption rates, making them highly resistant to moisture, stains, and wear. Both options provide versatile aesthetic choices, but porcelain tiles excel in high-traffic or moisture-prone areas due to their strength and durability.

Table of Comparison

| Feature | Ceramic Tiles | Porcelain Tiles |

|---|---|---|

| Material | Clay mixed with other natural materials | Denser clay, fired at higher temperatures |

| Durability | Moderate, suitable for low to moderate traffic | High, ideal for high traffic and outdoor use |

| Water Absorption Rate | Higher (over 0.5%) | Low (less than 0.5%), making it more water-resistant |

| Cost | Generally more affordable | More expensive due to manufacturing process |

| Design & Finish | Wide variety, often glazed | More uniform, can be glazed or unglazed |

| Installation | Easier to cut and install | Harder to cut due to density |

| Use Cases | Indoor walls, low-traffic floors | Indoor floors, outdoor areas, commercial spaces |

Introduction to Ceramic and Porcelain Tiles

Ceramic tiles are made from natural clay fired at lower temperatures, resulting in a porous and softer surface ideal for indoor use, while porcelain tiles are crafted from denser clay fired at higher temperatures, offering superior durability and water resistance suitable for both indoor and outdoor applications. Ceramic tiles typically feature a glazed surface that allows for a wide range of colors and patterns, whereas porcelain tiles have a denser composition that enhances strength and reduces moisture absorption. Both tile types provide versatile options for flooring and wall installations, with porcelain tiles often preferred for high-traffic areas due to their enhanced hardness and resilience.

Composition and Manufacturing Process

Ceramic tiles are primarily composed of natural clay and other minerals fired at lower temperatures, resulting in a more porous, softer material. Porcelain tiles use a finer, denser clay mixture fired at higher temperatures, creating a harder, less porous surface with enhanced durability. The manufacturing process of porcelain involves a vitrification stage that increases the tile's resistance to moisture and wear compared to ceramic tiles.

Durability and Strength Comparison

Porcelain tiles exhibit higher durability and strength compared to ceramic tiles due to their dense composition and lower water absorption rate, making them ideal for high-traffic areas. Ceramic tiles, while suitable for moderate use, are more prone to chipping and wear over time. Porcelain's superior hardness, measured by a higher PEI rating, ensures longer-lasting performance in both residential and commercial applications.

Water Absorption and Porosity

Ceramic tiles typically have higher water absorption rates, ranging from 3% to 7%, making them more porous compared to porcelain tiles, whose water absorption is less than 0.5%. This low porosity of porcelain tiles results from their denser composition and higher firing temperature, providing superior moisture resistance. Consequently, porcelain tiles are more suitable for areas with high humidity and moisture exposure, such as bathrooms and outdoor spaces.

Design, Patterns, and Finish Options

Ceramic tiles offer a wide variety of designs, patterns, and finishes, including matte, glossy, and textured options that enhance aesthetic appeal for residential spaces. Porcelain tiles are denser and provide more intricate patterns and high-definition prints, suitable for high-traffic areas requiring both beauty and durability. Both tile types support customizable finishes, but porcelain's fine-grain composition allows for sharper, more detailed designs with superior stain and moisture resistance.

Installation Differences and Techniques

Ceramic tiles are generally easier to cut and shape during installation due to their softer composition, allowing for quicker adjustments on-site compared to denser porcelain tiles. Porcelain tiles require specialized tools such as diamond-tipped blades and wet saws to achieve precise cuts and prevent cracking, reflecting their higher durability and hardness. Both types typically utilize thin-set mortar, but porcelain installation demands a more meticulous substrate preparation to ensure proper adhesion and long-term stability.

Maintenance and Cleaning Requirements

Ceramic tiles require regular maintenance with gentle cleaning agents to prevent surface wear, as their porous nature makes them more susceptible to staining. Porcelain tiles are denser and less porous, offering superior resistance to moisture and stains, which translates to lower maintenance and easier cleaning with mild detergents. Both types benefit from routine sweeping and mopping, but porcelain tiles typically maintain their appearance longer with less frequent deep cleaning.

Cost and Budget Considerations

Ceramic tiles generally cost less than porcelain tiles, making them a more budget-friendly option for large-scale projects or home renovations. Porcelain tiles, although pricier, offer greater durability and lower water absorption, which can reduce long-term maintenance expenses. Homeowners should balance upfront costs with longevity and performance requirements when choosing between ceramic and porcelain tiles.

Best Applications: Where to Use Each Tile

Ceramic tiles are best suited for low-traffic areas such as bathrooms and kitchens due to their porous nature and softer composition, providing easy installation and cost efficiency. Porcelain tiles, being denser and more water-resistant, excel in high-traffic zones like commercial spaces, entryways, and outdoor patios where durability and moisture resistance are critical. Choosing based on environment-specific needs ensures optimal performance and longevity for either ceramic or porcelain options.

Environmental Impact and Sustainability

Porcelain tiles have a lower water absorption rate compared to ceramic tiles, making them more durable and less prone to damage, which extends their lifespan and reduces waste. The manufacturing process of porcelain tiles requires higher firing temperatures, resulting in greater energy consumption but produces a denser and less porous material, contributing to long-term sustainability. Ceramic tiles often contain natural clay and minerals sourced locally, potentially lowering transportation emissions, while porcelain's durability supports sustainable building practices through reduced replacement frequency.

Ceramic tiles vs Porcelain tiles Infographic

materialdif.com

materialdif.com