Ceramic coatings offer superior durability and heat resistance compared to Teflon coatings, making them ideal for high-temperature cooking and industrial applications. Unlike Teflon, ceramic coatings are typically free of harmful chemicals like PTFE and PFOA, providing a safer, non-toxic surface. The enhanced hardness and scratch resistance of ceramic coatings also ensure longer-lasting performance and easier maintenance.

Table of Comparison

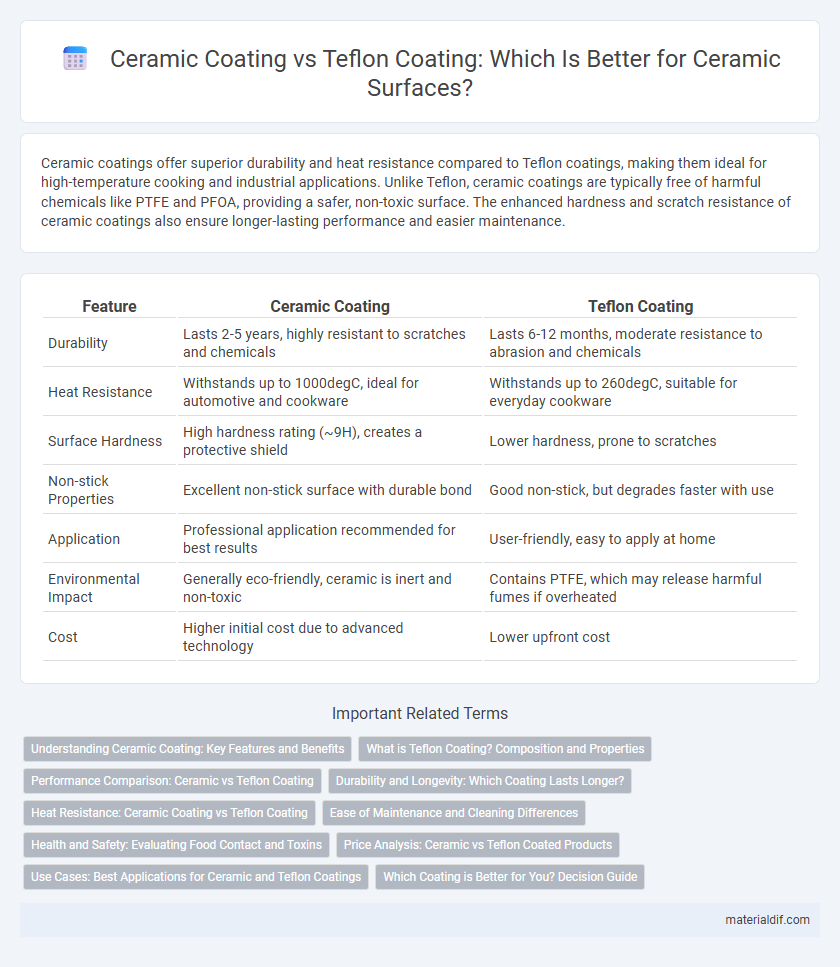

| Feature | Ceramic Coating | Teflon Coating |

|---|---|---|

| Durability | Lasts 2-5 years, highly resistant to scratches and chemicals | Lasts 6-12 months, moderate resistance to abrasion and chemicals |

| Heat Resistance | Withstands up to 1000degC, ideal for automotive and cookware | Withstands up to 260degC, suitable for everyday cookware |

| Surface Hardness | High hardness rating (~9H), creates a protective shield | Lower hardness, prone to scratches |

| Non-stick Properties | Excellent non-stick surface with durable bond | Good non-stick, but degrades faster with use |

| Application | Professional application recommended for best results | User-friendly, easy to apply at home |

| Environmental Impact | Generally eco-friendly, ceramic is inert and non-toxic | Contains PTFE, which may release harmful fumes if overheated |

| Cost | Higher initial cost due to advanced technology | Lower upfront cost |

Understanding Ceramic Coating: Key Features and Benefits

Ceramic coating offers superior durability and heat resistance compared to Teflon coating, with a hard, glass-like layer that protects surfaces from scratches, stains, and corrosion. Its non-porous nature enhances resistance to chemicals and high temperatures, extending the lifespan of cookware and automotive parts. Unlike Teflon, ceramic coatings are typically free from harmful chemicals like PTFE and PFOA, making them a safer and more environmentally friendly option.

What is Teflon Coating? Composition and Properties

Teflon coating is a non-stick surface layer made from polytetrafluoroethylene (PTFE), a synthetic fluoropolymer known for its low friction and chemical resistance. Its composition consists primarily of carbon and fluorine atoms arranged to form a slippery, non-reactive barrier that repels water, oils, and various chemicals. Teflon coatings offer excellent heat resistance up to 260degC, outstanding release properties, and durability, making them ideal for cookware and industrial applications.

Performance Comparison: Ceramic vs Teflon Coating

Ceramic coatings offer superior heat resistance and durability compared to Teflon coatings, making them ideal for high-temperature applications and extended wear. Teflon coatings provide excellent non-stick properties but tend to degrade faster under abrasive conditions and elevated heat. Performance-wise, ceramic coatings maintain their integrity and protective qualities longer, especially in environments requiring high scratch and thermal resistance.

Durability and Longevity: Which Coating Lasts Longer?

Ceramic coatings offer superior durability and longevity compared to Teflon coatings due to their ability to withstand higher temperatures and resist abrasion, chemicals, and UV damage. While Teflon coatings provide effective non-stick properties, they typically degrade faster under harsh conditions, wearing off within months to a year depending on usage. Ceramic coatings can last several years, maintaining their protective qualities and preserving surfaces with minimal maintenance.

Heat Resistance: Ceramic Coating vs Teflon Coating

Ceramic coating offers superior heat resistance compared to Teflon coating, withstanding temperatures up to 1,200degF (650degC) without breaking down. Teflon coating typically degrades at temperatures above 500degF (260degC), limiting its use in high-heat applications. This makes ceramic coatings ideal for cookware, automotive parts, and industrial machinery exposed to extreme heat.

Ease of Maintenance and Cleaning Differences

Ceramic coatings offer superior ease of maintenance due to their hydrophobic properties, causing liquids and stains to bead off surfaces effortlessly, reducing the need for frequent cleaning. Teflon coatings, while providing a slick surface, tend to degrade faster with repeated use and can retain oils and grime, making cleaning more labor-intensive over time. Ceramic coatings also resist heat and chemical damage better, ensuring long-lasting protection and simpler upkeep compared to Teflon.

Health and Safety: Evaluating Food Contact and Toxins

Ceramic coatings are generally non-toxic and free from harmful chemicals, making them safer for direct food contact compared to some Teflon coatings that may release toxic fumes if overheated. Ceramic's inorganic composition provides a stable, inert surface less likely to leach hazardous substances during cooking, enhancing health safety. Teflon coatings, made from polytetrafluoroethylene (PTFE), can degrade under extreme temperatures, potentially emitting perfluorooctanoic acid (PFOA) and other toxic compounds linked to health risks.

Price Analysis: Ceramic vs Teflon Coated Products

Ceramic coatings often command higher prices due to their superior durability, heat resistance, and scratch protection in comparison to Teflon coatings. Teflon coated products are generally more affordable but may require more frequent replacement or recoating, impacting long-term cost efficiency. Evaluating the price per usage period reveals that ceramic coatings can be more cost-effective despite their upfront expense.

Use Cases: Best Applications for Ceramic and Teflon Coatings

Ceramic coatings excel in automotive and industrial applications due to their superior heat resistance, hardness, and long-lasting protection against corrosion and abrasion. Teflon coatings are ideal for cookware and non-stick surfaces where low friction and chemical resistance are critical, offering ease of cleaning and food release. Choosing between ceramic and Teflon coatings depends on the need for durability and heat tolerance versus non-stick properties and low friction performance.

Which Coating is Better for You? Decision Guide

Ceramic coating offers superior durability and heat resistance compared to Teflon coating, making it ideal for high-temperature cooking and long-lasting performance. Teflon coating provides excellent non-stick properties and is usually more affordable, but it tends to wear out faster and may release harmful fumes if overheated. Choosing between ceramic and Teflon coatings depends on your cooking habits, budget, and health considerations, with ceramic favored for longevity and non-toxicity, while Teflon suits low-to-medium heat cooking.

Ceramic coating vs Teflon coating Infographic

materialdif.com

materialdif.com