Bisque refers to pottery that has been fired once without glaze, resulting in a porous and matte surface ideal for decoration or glazing. Glaze is a glassy coating applied to bisque-fired ceramics, which vitrifies during a second firing to create a smooth, non-porous, and often glossy finish. Understanding the difference between bisque and glaze is essential for ceramic artists to achieve desired textures, durability, and aesthetic effects in their creations.

Table of Comparison

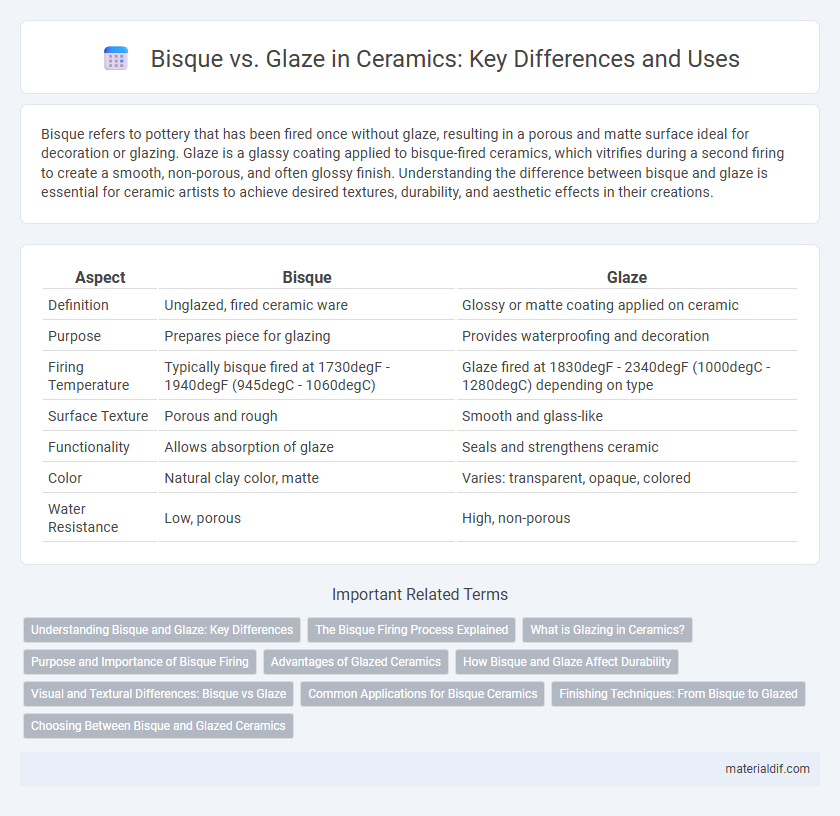

| Aspect | Bisque | Glaze |

|---|---|---|

| Definition | Unglazed, fired ceramic ware | Glossy or matte coating applied on ceramic |

| Purpose | Prepares piece for glazing | Provides waterproofing and decoration |

| Firing Temperature | Typically bisque fired at 1730degF - 1940degF (945degC - 1060degC) | Glaze fired at 1830degF - 2340degF (1000degC - 1280degC) depending on type |

| Surface Texture | Porous and rough | Smooth and glass-like |

| Functionality | Allows absorption of glaze | Seals and strengthens ceramic |

| Color | Natural clay color, matte | Varies: transparent, opaque, colored |

| Water Resistance | Low, porous | High, non-porous |

Understanding Bisque and Glaze: Key Differences

Bisque refers to ceramic ware that has been fired once without glaze, resulting in a porous surface ideal for glazing or painting. Glaze is a glassy coating applied to bisque ware and fired again at high temperatures, creating a non-porous, glossy, or matte finish that enhances durability and aesthetics. Understanding bisque versus glaze is crucial for ceramic artists to control texture, color application, and the final functional properties of pottery.

The Bisque Firing Process Explained

Bisque firing is the initial kiln firing in ceramics that transforms raw clay into a porous, durable state known as bisqueware, enabling it to absorb glaze effectively. This process typically occurs at temperatures between 1,800degF and 1,940degF (980degC to 1,060degC), removing physical and chemical water from the clay while strengthening the piece. Bisque firing is essential for preparing ceramics for glaze application, ensuring the glaze adheres properly during the subsequent glaze firing.

What is Glazing in Ceramics?

Glazing in ceramics refers to applying a glass-like coating to bisque-fired pottery, creating a smooth, often glossy surface that enhances durability and aesthetic appeal. This layer seals the porous bisque clay, making vessels waterproof and resistant to stains and scratches. Various glaze recipes and firing temperatures affect the final color, texture, and finish of ceramic pieces.

Purpose and Importance of Bisque Firing

Bisque firing transforms fragile clay into a porous, durable state ideal for glaze application, ensuring proper adhesion and preventing defects during the final glaze firing. This essential first firing removes moisture and organic materials, stabilizing the ceramic piece's structure and enhancing its strength. Without bisque firing, glaze may pool unevenly or cause cracking, compromising both the aesthetics and durability of ceramic artworks.

Advantages of Glazed Ceramics

Glazed ceramics offer enhanced durability and water resistance, protecting the bisque ware from moisture and stains. The glossy or matte finish provided by glazing improves aesthetic appeal while sealing surface porosity to prevent dirt and bacteria accumulation. This protective layer also facilitates easier cleaning and extends the lifespan of ceramic items in everyday use.

How Bisque and Glaze Affect Durability

Bisque firing transforms clay into a porous, sturdy state that provides a durable foundation for glaze application, enhancing the overall strength and longevity of ceramic pieces. The glaze, when properly applied and vitrified during the glaze firing, creates a glassy, impermeable surface that protects bisque ware from moisture, stains, and mechanical wear. Together, bisque and glaze optimize the durability of ceramics by combining structural integrity with a resilient, protective coating.

Visual and Textural Differences: Bisque vs Glaze

Bisque ceramics exhibit a matte, porous surface with a rough texture that highlights the piece's raw, unglazed qualities, allowing for greater paint absorption and a natural, earthy appearance. Glazed ceramics, in contrast, feature a smooth, glossy finish that enhances color vibrancy and provides a waterproof, reflective surface, creating a polished and durable final product. The tactile contrast between bisque's gritty feel and glaze's slick, glass-like coating defines their distinct visual and textural identities in ceramic artistry.

Common Applications for Bisque Ceramics

Bisque ceramics are primarily used as the foundational stage in pottery and sculpture-making, allowing artists to apply glazes or paint without the risk of damage during firing. Common applications include creating durable, porous surfaces for functional ware like dinnerware, flower pots, and tiles that require glazing for waterproofing. Bisque-fired pieces serve as ideal canvases for decorative finishes, enhancing both aesthetic appeal and durability in ceramic art and commercial products.

Finishing Techniques: From Bisque to Glazed

Bisque firing transforms raw clay into a porous, hardened state ideal for absorbing glaze, enhancing surface durability and aesthetic appeal. Glazing involves applying a glassy coating that melts during a second firing, creating a smooth, waterproof, and often colorful finish essential for both functional and decorative ceramics. This two-step finishing technique optimizes strength and visual texture while preventing water penetration and surface damage.

Choosing Between Bisque and Glazed Ceramics

Choosing between bisque and glazed ceramics depends on the intended use and aesthetic preference; bisque ceramics offer a porous, matte surface ideal for painting and decoration, while glazed ceramics provide a waterproof, glossy finish that enhances durability and color vibrancy. Bisque firing typically occurs at lower temperatures, leaving a porous texture suited for further artistic customization, whereas glazing involves a higher temperature process that melts a glassy coating onto the ceramic body for protection and visual appeal. Understanding the functional demands and desired surface treatment helps determine whether bisque or glazed ceramics are the best choice for pottery, tableware, or decorative objects.

Bisque vs Glaze Infographic

materialdif.com

materialdif.com