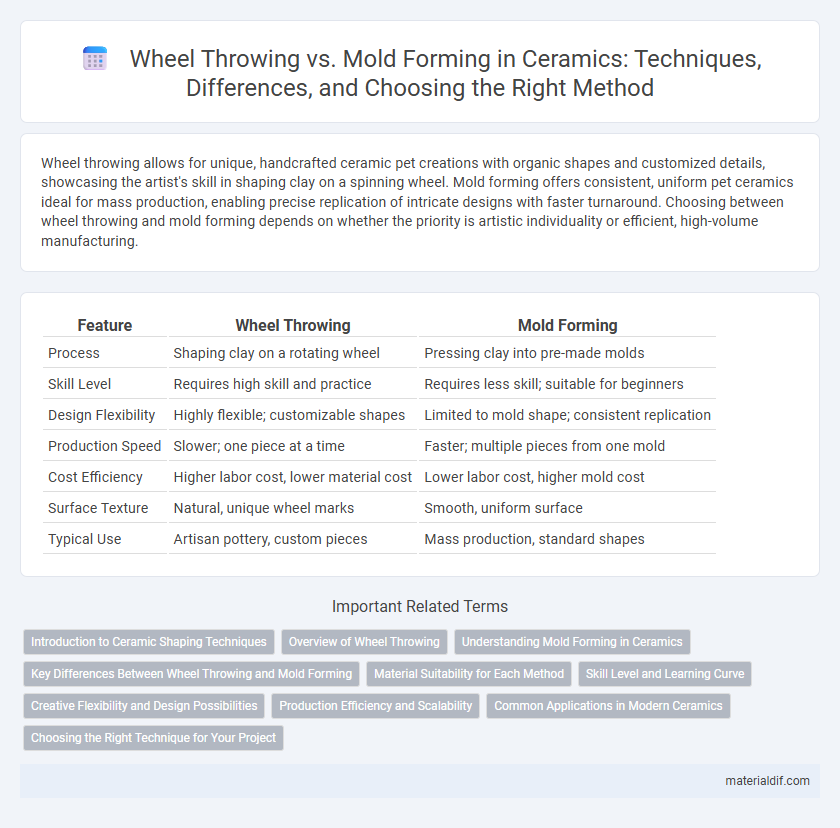

Wheel throwing allows for unique, handcrafted ceramic pet creations with organic shapes and customized details, showcasing the artist's skill in shaping clay on a spinning wheel. Mold forming offers consistent, uniform pet ceramics ideal for mass production, enabling precise replication of intricate designs with faster turnaround. Choosing between wheel throwing and mold forming depends on whether the priority is artistic individuality or efficient, high-volume manufacturing.

Table of Comparison

| Feature | Wheel Throwing | Mold Forming |

|---|---|---|

| Process | Shaping clay on a rotating wheel | Pressing clay into pre-made molds |

| Skill Level | Requires high skill and practice | Requires less skill; suitable for beginners |

| Design Flexibility | Highly flexible; customizable shapes | Limited to mold shape; consistent replication |

| Production Speed | Slower; one piece at a time | Faster; multiple pieces from one mold |

| Cost Efficiency | Higher labor cost, lower material cost | Lower labor cost, higher mold cost |

| Surface Texture | Natural, unique wheel marks | Smooth, uniform surface |

| Typical Use | Artisan pottery, custom pieces | Mass production, standard shapes |

Introduction to Ceramic Shaping Techniques

Wheel throwing involves shaping clay on a rotating potter's wheel, allowing for precise control over form and symmetry, ideal for creating round vessels like bowls and vases. Mold forming uses pre-shaped molds to press or slip-cast clay, enabling consistent replication of complex shapes and detailed patterns with minimal manual skill. Both techniques serve foundational roles in ceramic artistry, offering distinct advantages in design flexibility and production efficiency.

Overview of Wheel Throwing

Wheel throwing is a traditional ceramic technique involving shaping clay on a rapidly spinning potter's wheel, allowing for symmetrical and rounded forms such as bowls, vases, and plates. This method enables precise control over wall thickness and surface texture, making it ideal for both functional and artistic pottery. Skilled artisans use wheel throwing to achieve unique, handcrafted pieces with a tactile quality that differs from uniform mold-formed ceramics.

Understanding Mold Forming in Ceramics

Mold forming in ceramics involves shaping clay by pressing or pouring it into pre-made molds, allowing for precise replication of complex designs and fine details unattainable by wheel throwing. This technique increases production efficiency and consistency, making it ideal for mass manufacturing of intricate ceramic pieces like figurines, tiles, and tableware. Mold forming also reduces the skill barrier compared to wheel throwing, enabling artisans to produce uniform shapes without extensive training in manual throwing techniques.

Key Differences Between Wheel Throwing and Mold Forming

Wheel throwing involves shaping clay on a rotating potter's wheel, allowing for unique, handcrafted forms with fluid symmetry and individualized variations. Mold forming uses pre-made molds to produce uniform ceramic pieces quickly, ensuring consistency in size and shape for mass production. The key differences lie in the level of craftsmanship, production speed, and the degree of variation between each piece.

Material Suitability for Each Method

Wheel throwing is best suited for clay bodies with plasticity and smooth texture, such as stoneware and porcelain, which allow for even shaping and fine detail on the potter's wheel. Mold forming requires more fluid clay slips or less plastic, often using earthenware or terra cotta, enabling the material to flow and fill intricate molds effectively. Material choice impacts drying times and final strength, making selection critical for successful ceramic production with either technique.

Skill Level and Learning Curve

Wheel throwing demands a higher skill level and a steeper learning curve due to the need for precise hand coordination and continual adjustment of pressure to shape symmetrical pottery. Mold forming offers a more accessible technique for beginners, as it requires less manual dexterity and allows consistent replication of shapes using pre-made molds. Mastery of wheel throwing typically takes months of practice, while proficiency in mold forming can be achieved relatively quickly with minimal training.

Creative Flexibility and Design Possibilities

Wheel throwing offers unparalleled creative flexibility by allowing potters to shape symmetrical, intricate forms in real-time, adapting designs with subtle changes in pressure and speed. Mold forming provides consistent replication of complex shapes, ideal for mass production but limits spontaneous artistic variation. Combining both techniques can expand design possibilities, blending unique hand-crafted elements with precision and uniformity.

Production Efficiency and Scalability

Wheel throwing offers artisanal precision but is limited in production efficiency due to its labor-intensive, one-piece-at-a-time process. Mold forming excels in scalability, enabling high-volume output with consistent shapes and sizes while minimizing manual labor. Manufacturers seeking rapid, uniform production typically favor mold forming for streamlined workflow and cost-effectiveness.

Common Applications in Modern Ceramics

Wheel throwing is widely used for creating symmetrical vessels such as bowls, vases, and cups in artisanal pottery and fine ceramics. Mold forming excels in mass production of consistent shapes like plates, tiles, and decorative figurines, often found in commercial ceramic manufacturing. Both techniques complement modern ceramic production by balancing handcrafted uniqueness and efficient replication.

Choosing the Right Technique for Your Project

Wheel throwing offers precision and control ideal for symmetrical pottery, while mold forming excels in producing consistent, complex shapes efficiently. Selecting the right ceramic technique depends on project scale, desired texture, and time constraints. Artists prioritizing unique, handcrafted aesthetics often prefer wheel throwing, whereas manufacturers targeting mass production lean toward mold forming.

Wheel Throwing vs Mold Forming Infographic

materialdif.com

materialdif.com