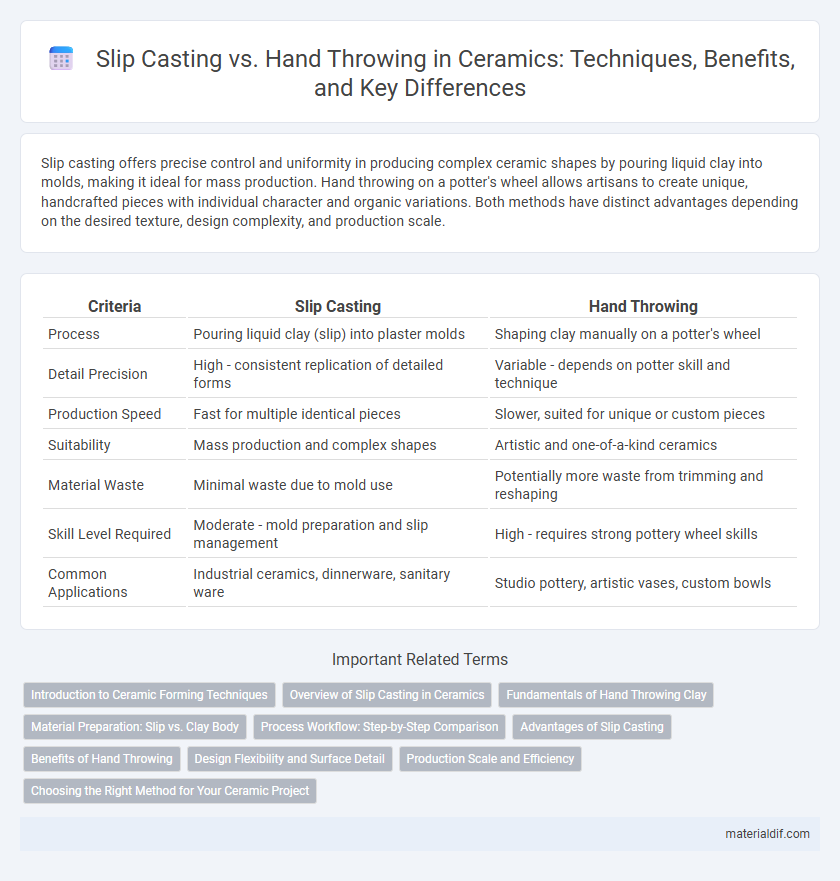

Slip casting offers precise control and uniformity in producing complex ceramic shapes by pouring liquid clay into molds, making it ideal for mass production. Hand throwing on a potter's wheel allows artisans to create unique, handcrafted pieces with individual character and organic variations. Both methods have distinct advantages depending on the desired texture, design complexity, and production scale.

Table of Comparison

| Criteria | Slip Casting | Hand Throwing |

|---|---|---|

| Process | Pouring liquid clay (slip) into plaster molds | Shaping clay manually on a potter's wheel |

| Detail Precision | High - consistent replication of detailed forms | Variable - depends on potter skill and technique |

| Production Speed | Fast for multiple identical pieces | Slower, suited for unique or custom pieces |

| Suitability | Mass production and complex shapes | Artistic and one-of-a-kind ceramics |

| Material Waste | Minimal waste due to mold use | Potentially more waste from trimming and reshaping |

| Skill Level Required | Moderate - mold preparation and slip management | High - requires strong pottery wheel skills |

| Common Applications | Industrial ceramics, dinnerware, sanitary ware | Studio pottery, artistic vases, custom bowls |

Introduction to Ceramic Forming Techniques

Slip casting involves pouring liquid clay (slip) into plaster molds, which absorb moisture and create precise, uniform ceramic shapes, ideal for complex or replicated designs. Hand throwing uses a potter's wheel to shape clay manually, allowing for greater artistic expression and unique, one-of-a-kind forms. Both techniques are fundamental in ceramic forming, with slip casting emphasizing consistency and hand throwing highlighting craftsmanship.

Overview of Slip Casting in Ceramics

Slip casting in ceramics involves pouring liquid clay slip into plaster molds, allowing for the production of intricate and uniform shapes that are difficult to achieve with hand throwing. This method excels in mass production, providing consistent wall thickness and detailed surface textures. Unlike hand throwing on a wheel, slip casting offers greater precision and repeatability for complex ceramic forms.

Fundamentals of Hand Throwing Clay

Hand throwing clay relies on mastering fundamental techniques such as centering, opening, and pulling the clay on a potter's wheel, requiring precise control and tactile feedback to shape symmetrical forms. Slip casting involves pouring liquid clay slip into molds, offering consistency and the ability to produce complex shapes but lacking the hands-on manipulation found in hand throwing. Understanding the physical interaction with clay during hand throwing enhances artistic expression and allows for unique surface textures and forms that are difficult to replicate with slip casting methods.

Material Preparation: Slip vs. Clay Body

Slip casting relies on a liquid clay mixture called slip, which is carefully prepared by blending clay particles with water to achieve a smooth, pourable consistency essential for filling molds. Hand throwing uses a more plastic, malleable clay body that must be wedged to remove air bubbles and attain uniform texture for effective shaping on the potter's wheel. Both techniques require precise control of moisture content, but slip casting prioritizes suspension stability while hand throwing emphasizes plasticity and coherence of the clay mass.

Process Workflow: Step-by-Step Comparison

Slip casting involves pouring liquid clay slip into plaster molds, allowing the plaster to absorb water and form a solid layer that is then removed and fired; this process is ideal for producing detailed, uniform shapes with minimal manual shaping. Hand throwing requires centering a clay ball on a spinning wheel and shaping it manually using hands and tools, offering greater artistic control and unique variations in each piece. Slip casting workflow is highly repeatable and efficient for mass production, while hand throwing emphasizes craftsmanship through an iterative, hands-on technique.

Advantages of Slip Casting

Slip casting offers precise replication of complex shapes and fine details, making it highly efficient for mass production of uniform ceramic pieces. It reduces material waste by using slip, a liquid clay mixture, ensuring better control over thickness and consistency. This method also enables faster drying times and easier integration with molds, improving overall manufacturing speed and quality.

Benefits of Hand Throwing

Hand throwing offers greater artistic control and allows for unique, one-of-a-kind ceramic pieces with varied shapes and textures. This method enhances tactile feedback, enabling potters to make real-time adjustments that perfectly match their creative vision. The process fosters a deeper connection between the artist and the clay, resulting in ceramics with distinct character and craftsmanship.

Design Flexibility and Surface Detail

Slip casting offers superior design flexibility, enabling intricate shapes and consistent reproductions that are difficult to achieve with hand throwing. Hand throwing allows for unique surface details and organic textures, reflecting the potter's individual touch and spontaneity in each piece. Surface finishes in slip casting tend to be smoother and more uniform, while hand-thrown ceramics feature more varied and tactile details.

Production Scale and Efficiency

Slip casting enables high-volume production of intricate ceramic shapes with consistent precision, making it ideal for mass manufacturing. Hand throwing offers greater artistic flexibility but is less efficient for large-scale production due to its time-intensive, skill-dependent process. Factories prioritize slip casting for efficiency, while studios and artisans favor hand throwing for unique, custom pieces.

Choosing the Right Method for Your Ceramic Project

Slip casting offers precise replication and uniformity, ideal for intricate designs or mass production in ceramic projects. Hand throwing provides greater artistic freedom and unique variations, perfect for customized, one-of-a-kind pieces. Selecting the right method depends on project goals, desired texture, and production scale, balancing efficiency and creative expression.

Slip Casting vs Hand Throwing Infographic

materialdif.com

materialdif.com