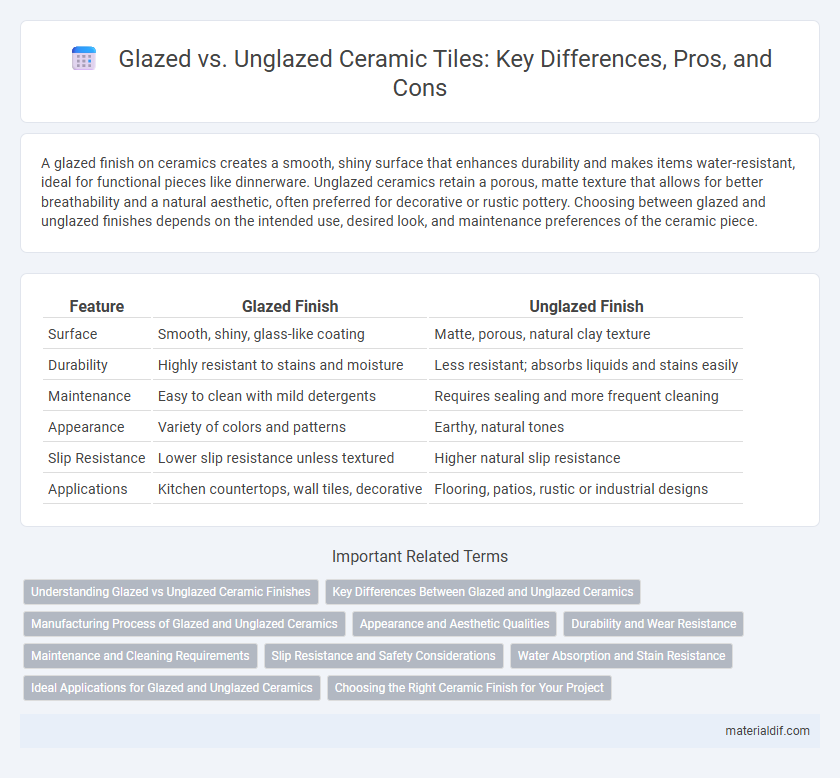

A glazed finish on ceramics creates a smooth, shiny surface that enhances durability and makes items water-resistant, ideal for functional pieces like dinnerware. Unglazed ceramics retain a porous, matte texture that allows for better breathability and a natural aesthetic, often preferred for decorative or rustic pottery. Choosing between glazed and unglazed finishes depends on the intended use, desired look, and maintenance preferences of the ceramic piece.

Table of Comparison

| Feature | Glazed Finish | Unglazed Finish |

|---|---|---|

| Surface | Smooth, shiny, glass-like coating | Matte, porous, natural clay texture |

| Durability | Highly resistant to stains and moisture | Less resistant; absorbs liquids and stains easily |

| Maintenance | Easy to clean with mild detergents | Requires sealing and more frequent cleaning |

| Appearance | Variety of colors and patterns | Earthy, natural tones |

| Slip Resistance | Lower slip resistance unless textured | Higher natural slip resistance |

| Applications | Kitchen countertops, wall tiles, decorative | Flooring, patios, rustic or industrial designs |

Understanding Glazed vs Unglazed Ceramic Finishes

Glazed ceramic finishes offer a smooth, shiny surface that enhances durability, resists stains, and provides water resistance, making them ideal for kitchens and bathrooms. Unglazed ceramics feature a matte, porous texture that offers natural slip resistance and a more rustic aesthetic, often preferred for outdoor or high-traffic flooring. Choosing between glazed and unglazed finishes depends on the intended use, maintenance requirements, and desired appearance of the ceramic product.

Key Differences Between Glazed and Unglazed Ceramics

Glazed ceramics feature a glass-like coating that enhances durability, water resistance, and provides a glossy or matte aesthetic, while unglazed ceramics have a porous surface that absorbs moisture and offers a natural, textured feel. The glazing process seals the ceramic body, preventing stains and increasing hardness, making glazed ceramics ideal for kitchenware and decorative tiles. Unglazed ceramics, often preferred for their rustic appearance and breathability, are commonly used in flower pots and cookware like terracotta.

Manufacturing Process of Glazed and Unglazed Ceramics

The manufacturing process of glazed ceramics involves applying a glassy coating to the surface, which is then fired at high temperatures to create a smooth, glossy finish that enhances durability and water resistance. Unglazed ceramics undergo firing without this coating, preserving the natural porous texture of the clay body and often requiring precise temperature control to avoid cracking or warping. Differences in firing temperatures and surface treatments directly impact the strength, aesthetic, and functional properties of glazed versus unglazed ceramic products.

Appearance and Aesthetic Qualities

Glazed ceramic finishes offer a smooth, glossy surface that enhances color vibrancy and provides a reflective sheen, elevating the visual appeal in interior and architectural applications. Unglazed ceramic maintains a matte, natural texture that emphasizes raw, earthy tones and subtle variations, ideal for achieving rustic or minimalist aesthetics. Both finishes impact slip resistance and light interaction, with glazed surfaces appearing more polished while unglazed options present a muted, understated elegance.

Durability and Wear Resistance

Glazed ceramic finishes offer superior durability and enhanced wear resistance due to their glass-like coating that protects against scratches, stains, and moisture penetration. Unglazed ceramics, while more porous, provide better slip resistance and maintain their appearance over time with moderate wear resistance. Choosing between glazed and unglazed finishes depends on the specific application requirements for durability and surface texture in ceramic products.

Maintenance and Cleaning Requirements

Glazed ceramic surfaces feature a smooth, non-porous coating that resists stains and simplifies cleaning, requiring only regular wiping with mild detergents to maintain their shine and hygiene. Unglazed ceramic, being porous, tends to absorb dirt and moisture, necessitating frequent sealing and deeper cleaning with specialized products to prevent staining and mold growth. Maintenance of glazed ceramics is generally less demanding and more cost-effective compared to the ongoing care and protection needed for unglazed finishes.

Slip Resistance and Safety Considerations

Glazed finish ceramics provide a smooth, shiny surface that can become slippery when wet, posing safety concerns in high-traffic or wet areas. Unglazed ceramics offer better slip resistance due to their textured, matte surface, making them ideal for locations requiring enhanced grip. Selecting between glazed and unglazed finishes depends on balancing aesthetic preferences with safety requirements, particularly in environments prone to moisture.

Water Absorption and Stain Resistance

Glazed ceramic finishes significantly reduce water absorption by creating a non-porous surface, enhancing stain resistance and durability. Unglazed ceramics tend to absorb more water due to their porous nature, making them more susceptible to staining and requiring regular sealing. Optimal glaze application improves both moisture resistance and the longevity of ceramic tiles in high-traffic or wet environments.

Ideal Applications for Glazed and Unglazed Ceramics

Glazed ceramics are ideal for applications requiring water resistance and easy cleaning, such as kitchenware, bathroom tiles, and decorative items, due to their non-porous, shiny surface. Unglazed ceramics are preferred for outdoor paving, terracotta pots, and artistic sculptures, offering better slip resistance, natural texture, and breathability. The choice between glazed and unglazed finishes depends on durability needs, aesthetic preferences, and environmental exposure.

Choosing the Right Ceramic Finish for Your Project

Glazed ceramic finishes offer a smooth, non-porous surface that resists stains, water, and scratches, making them ideal for kitchens, bathrooms, and high-traffic areas. Unglazed ceramic provides a natural, textured appearance with superior slip resistance, suitable for outdoor spaces or rustic designs where durability and traction are priorities. Selecting the right finish depends on the specific application requirements, balancing aesthetics with practical factors like maintenance, durability, and environmental conditions.

Glazed Finish vs Unglazed Finish Infographic

materialdif.com

materialdif.com