Ceramic materials exhibit exceptional thermal shock resistance, allowing them to withstand rapid temperature changes without cracking or deforming. This property is often balanced against mechanical strength, which varies depending on composition and microstructure, influencing durability under stress. Selecting ceramics with an optimal combination of thermal shock resistance and mechanical strength is crucial for high-performance applications in aerospace, engineering, and electronics.

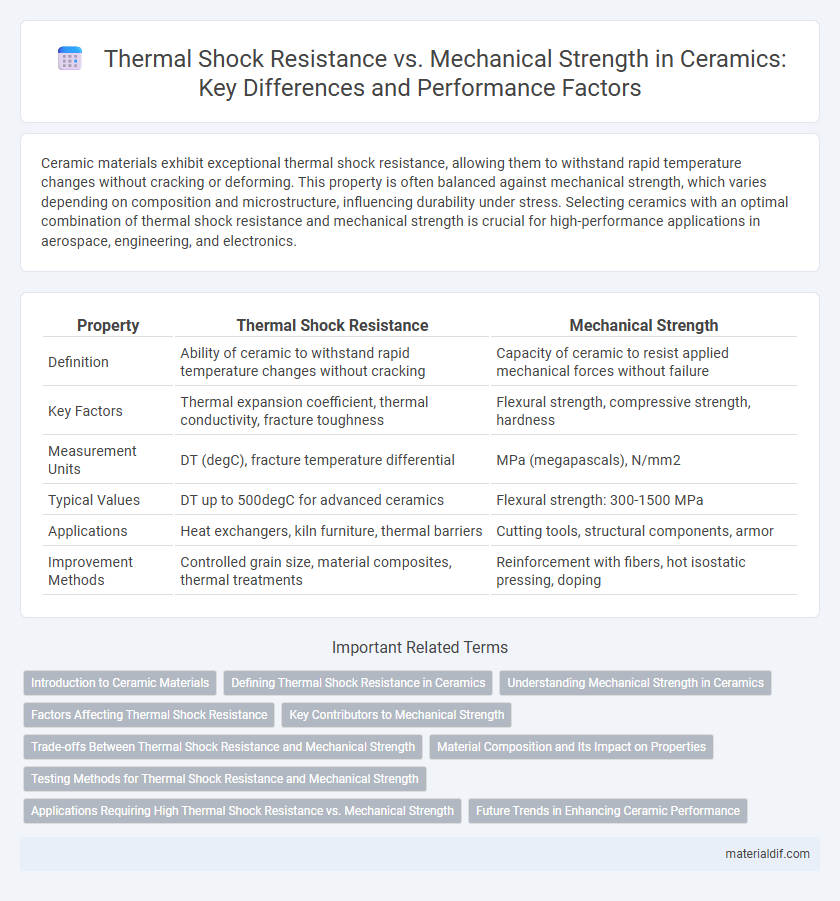

Table of Comparison

| Property | Thermal Shock Resistance | Mechanical Strength |

|---|---|---|

| Definition | Ability of ceramic to withstand rapid temperature changes without cracking | Capacity of ceramic to resist applied mechanical forces without failure |

| Key Factors | Thermal expansion coefficient, thermal conductivity, fracture toughness | Flexural strength, compressive strength, hardness |

| Measurement Units | DT (degC), fracture temperature differential | MPa (megapascals), N/mm2 |

| Typical Values | DT up to 500degC for advanced ceramics | Flexural strength: 300-1500 MPa |

| Applications | Heat exchangers, kiln furniture, thermal barriers | Cutting tools, structural components, armor |

| Improvement Methods | Controlled grain size, material composites, thermal treatments | Reinforcement with fibers, hot isostatic pressing, doping |

Introduction to Ceramic Materials

Ceramic materials exhibit exceptional thermal shock resistance due to their ability to withstand rapid temperature changes without cracking, making them ideal for high-temperature applications. Their mechanical strength, influenced by factors such as grain size and porosity, determines their ability to resist fracture under stress. Understanding the balance between thermal shock resistance and mechanical strength is crucial for optimizing ceramic performance in industrial and engineering contexts.

Defining Thermal Shock Resistance in Ceramics

Thermal shock resistance in ceramics refers to the material's ability to withstand rapid temperature changes without cracking or failing. It depends on factors such as thermal conductivity, coefficient of thermal expansion, and mechanical strength, which collectively influence how the ceramic dissipates stress caused by sudden heating or cooling. High thermal shock resistance is critical for applications involving extreme temperature fluctuations, ensuring durability and structural integrity under thermal stress.

Understanding Mechanical Strength in Ceramics

Mechanical strength in ceramics is determined by the material's microstructure, including grain size, porosity, and the presence of flaws or cracks. High mechanical strength enables ceramics to withstand significant compressive and tensile forces, essential for applications requiring durability and resistance to fracture. Understanding the balance between thermal shock resistance and mechanical strength is critical, as enhancing one property can often impact the other, influencing the overall performance of ceramic components.

Factors Affecting Thermal Shock Resistance

Thermal shock resistance in ceramics depends primarily on factors such as thermal conductivity, coefficient of thermal expansion, and fracture toughness. Materials with high thermal conductivity and low thermal expansion minimize internal stresses during rapid temperature changes, enhancing resistance. Additionally, improved mechanical strength, particularly fracture toughness, helps ceramics withstand thermal shock by preventing crack propagation.

Key Contributors to Mechanical Strength

Key contributors to mechanical strength in ceramics include the intrinsic material properties such as grain size, porosity, and the presence of microstructural defects like cracks or inclusions. The bonding strength between grains and the ceramic's ability to resist crack propagation directly influence its toughness and durability. Optimizing these factors enhances the ceramic's resistance to mechanical stresses, ensuring better performance under thermal shock conditions.

Trade-offs Between Thermal Shock Resistance and Mechanical Strength

Ceramic materials with high thermal shock resistance often exhibit lower mechanical strength due to their ability to absorb and dissipate rapid temperature changes without cracking. Enhancing mechanical strength typically involves increasing material density or stiffness, which can reduce thermal shock tolerance by limiting strain accommodation. Engineers must balance these trade-offs by selecting ceramic compositions and microstructures that optimize both properties for specific industrial applications.

Material Composition and Its Impact on Properties

Material composition in ceramics critically influences both thermal shock resistance and mechanical strength, with factors like grain size, phase distribution, and bonding type playing key roles. Ceramics containing fine-grained microstructures and strong covalent or ionic bonds typically exhibit enhanced mechanical strength, while compositions incorporating thermal expansion mismatches or secondary phases can improve thermal shock resistance by dissipating stress. Balancing oxide and non-oxide materials allows engineers to tailor ceramics for specific applications by optimizing fracture toughness alongside thermal stability.

Testing Methods for Thermal Shock Resistance and Mechanical Strength

Thermal shock resistance in ceramics is evaluated through rapid temperature cycling tests, exposing samples to sudden temperature changes to measure crack initiation and propagation. Mechanical strength is commonly assessed using flexural strength tests such as three-point or four-point bending, determining the material's ability to withstand applied loads without fracture. Combining these testing methods provides a comprehensive understanding of a ceramic's durability under thermal and mechanical stresses.

Applications Requiring High Thermal Shock Resistance vs. Mechanical Strength

Ceramics used in applications requiring high thermal shock resistance, such as furnace linings and heat exchangers, are engineered to withstand rapid temperature changes without cracking. Conversely, applications like structural components and cutting tools prioritize mechanical strength to endure high stress and wear. Balancing thermal shock resistance with mechanical strength is crucial for materials exposed to fluctuating temperatures and mechanical loads simultaneously.

Future Trends in Enhancing Ceramic Performance

Future trends in enhancing ceramic performance focus on developing nanostructured composites that balance thermal shock resistance with mechanical strength. Innovations in additive manufacturing enable precise microstructural control, improving crack deflection and energy absorption capabilities. Advanced doping techniques and interface engineering further optimize thermal stability while maintaining superior hardness and toughness metrics.

Thermal Shock Resistance vs Mechanical Strength Infographic

materialdif.com

materialdif.com