Ceramic additive manufacturing offers unparalleled design flexibility, enabling the creation of complex geometries that are difficult or impossible with traditional molding techniques. This advanced process reduces material waste and shortens production timelines by building components layer by layer directly from digital models. In contrast, traditional molding involves labor-intensive tooling and longer setup times, limiting customization and increasing the risk of defects in intricate ceramic parts.

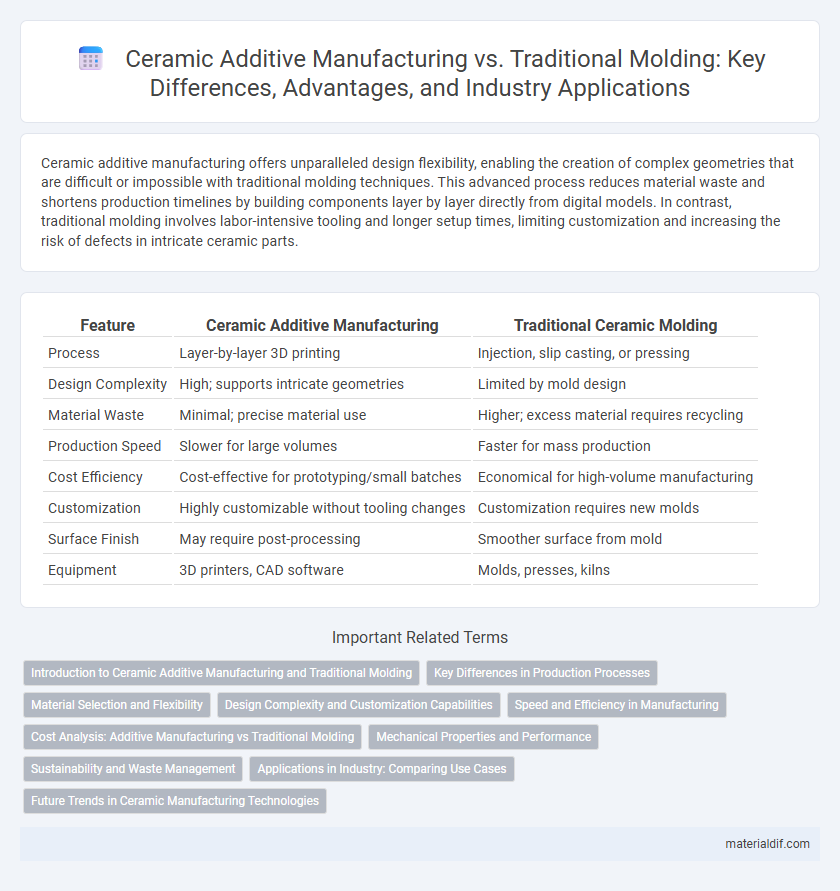

Table of Comparison

| Feature | Ceramic Additive Manufacturing | Traditional Ceramic Molding |

|---|---|---|

| Process | Layer-by-layer 3D printing | Injection, slip casting, or pressing |

| Design Complexity | High; supports intricate geometries | Limited by mold design |

| Material Waste | Minimal; precise material use | Higher; excess material requires recycling |

| Production Speed | Slower for large volumes | Faster for mass production |

| Cost Efficiency | Cost-effective for prototyping/small batches | Economical for high-volume manufacturing |

| Customization | Highly customizable without tooling changes | Customization requires new molds |

| Surface Finish | May require post-processing | Smoother surface from mold |

| Equipment | 3D printers, CAD software | Molds, presses, kilns |

Introduction to Ceramic Additive Manufacturing and Traditional Molding

Ceramic additive manufacturing utilizes layer-by-layer deposition techniques such as selective laser sintering (SLS) and binder jetting to create complex ceramic components with high precision and minimal material waste. Traditional molding involves shaping ceramics through processes like slip casting, injection molding, or pressing, relying heavily on molds and often resulting in longer production cycles and limited design flexibility. The advancement of ceramic additive manufacturing enables rapid prototyping and customization, contrasting with the repeatability and scalability advantages typical of traditional molding methods.

Key Differences in Production Processes

Ceramic additive manufacturing builds objects layer-by-layer using digital models, enabling complex geometries and customization with minimal material waste. In contrast, traditional molding involves shaping ceramics through molds and high-pressure compaction, often requiring longer lead times and higher tooling costs. Additive techniques typically offer faster prototyping and reduced production cycles, while traditional molding excels in high-volume manufacturing with established repeatability.

Material Selection and Flexibility

Ceramic additive manufacturing offers superior material selection flexibility compared to traditional molding, enabling the use of complex ceramic compositions and custom blends tailored for specific performance requirements. Unlike traditional molding, which often relies on standardized materials due to processing constraints, additive techniques support intricate geometries and graded material properties without additional tooling costs. This flexibility accelerates prototyping and allows precise control over microstructure, enhancing the mechanical and thermal properties of ceramic components.

Design Complexity and Customization Capabilities

Ceramic additive manufacturing enables intricate geometries and complex internal structures that are unattainable with traditional molding techniques, enhancing design flexibility and functional performance. Customization through additive processes allows for rapid iteration and bespoke production without the need for expensive molds or tooling changes. Traditional ceramic molding is limited by fixed molds, resulting in less adaptability and longer lead times for design modifications.

Speed and Efficiency in Manufacturing

Ceramic Additive Manufacturing accelerates production by enabling rapid prototyping and minimizing setup time compared to Traditional Molding, which requires extensive mold preparation and curing cycles. The layer-by-layer construction in additive processes allows for complex geometries without additional tooling, significantly reducing lead times. This efficiency translates to lower material waste and faster iteration cycles, enhancing overall manufacturing throughput in ceramic production.

Cost Analysis: Additive Manufacturing vs Traditional Molding

Ceramic additive manufacturing reduces tooling costs significantly compared to traditional molding by eliminating the need for expensive molds and dies. Production expenses in additive manufacturing are driven primarily by material usage and machine operation time, enabling cost-effective small-batch or customized parts. Traditional molding incurs high upfront costs for mold fabrication, making it more economical only at large production volumes where these fixed costs can be amortized.

Mechanical Properties and Performance

Ceramic additive manufacturing enables precise control over microstructure, resulting in enhanced mechanical properties such as higher fracture toughness and improved wear resistance compared to traditional molding. Unlike conventional processes, additive techniques minimize defects and allow complex geometries that enhance load distribution and performance under stress. This technological advancement leads to ceramics with superior strength, durability, and tailored functionality for demanding industrial applications.

Sustainability and Waste Management

Ceramic additive manufacturing significantly reduces material waste by precisely depositing raw materials layer-by-layer, unlike traditional molding which often involves excess slurry and trimming waste. The process lowers energy consumption as it eliminates the need for molds and enables on-demand production, minimizing inventory and transportation emissions. Enhanced recyclability of unused powders in additive manufacturing further supports sustainable practices, promoting efficient resource utilization in ceramic production.

Applications in Industry: Comparing Use Cases

Ceramic additive manufacturing enables complex geometries and customized components in aerospace, medical implants, and electronics, surpassing traditional molding's limitations in design flexibility and prototyping speed. Traditional molding remains dominant in high-volume production of standard ceramic parts such as insulators, tiles, and automotive components due to cost-efficiency and established processes. Industrial use cases favor additive manufacturing for rapid innovation and lightweight structures, while molding sustains mass production and repeatability in ceramic manufacturing.

Future Trends in Ceramic Manufacturing Technologies

Ceramic additive manufacturing is revolutionizing future ceramic production by enabling complex geometries and material efficiency beyond traditional molding constraints. Emerging technologies like binder jetting and stereolithography offer enhanced precision and customization, reducing waste and lead times in ceramic manufacturing. Integration of AI-driven process optimization and hybrid techniques is anticipated to further advance the scalability and mechanical properties of ceramic components.

Ceramic Additive Manufacturing vs Traditional Molding Infographic

materialdif.com

materialdif.com