Lead-free glaze offers a safer and environmentally friendly option for ceramic pet products, eliminating the risk of toxic lead exposure that can harm pets and humans alike. Unlike leaded glazes, lead-free alternatives maintain vibrant colors and durability without compromising health standards. Choosing lead-free glaze ensures safer use, especially in items like pet bowls and toys that come into direct contact with animals.

Table of Comparison

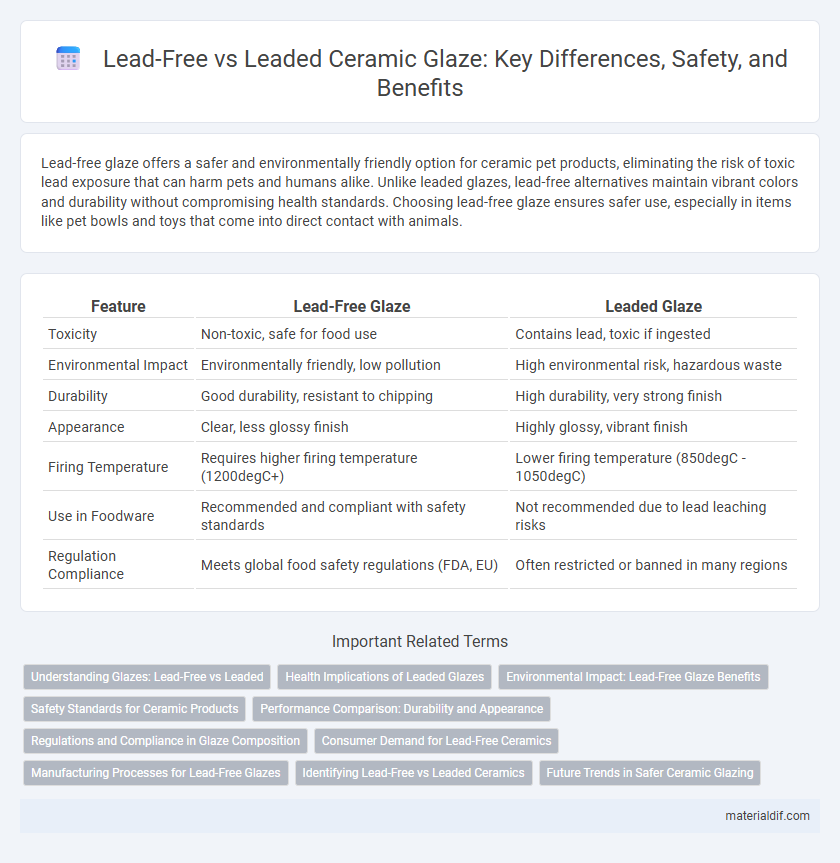

| Feature | Lead-Free Glaze | Leaded Glaze |

|---|---|---|

| Toxicity | Non-toxic, safe for food use | Contains lead, toxic if ingested |

| Environmental Impact | Environmentally friendly, low pollution | High environmental risk, hazardous waste |

| Durability | Good durability, resistant to chipping | High durability, very strong finish |

| Appearance | Clear, less glossy finish | Highly glossy, vibrant finish |

| Firing Temperature | Requires higher firing temperature (1200degC+) | Lower firing temperature (850degC - 1050degC) |

| Use in Foodware | Recommended and compliant with safety standards | Not recommended due to lead leaching risks |

| Regulation Compliance | Meets global food safety regulations (FDA, EU) | Often restricted or banned in many regions |

Understanding Glazes: Lead-Free vs Leaded

Lead-free glazes offer a safer alternative to leaded glazes by eliminating toxic lead compounds, reducing health risks during firing and use. While leaded glazes provide vibrant colors and smooth finishes due to their lower melting points, lead-free options utilize non-toxic fluxes like barium or boron to achieve durability and sheen. Understanding the chemical composition and firing temperature differences between lead-free and leaded glazes is crucial for ceramic artists prioritizing safety without compromising aesthetic quality.

Health Implications of Leaded Glazes

Leaded glazes contain toxic heavy metals that can leach into food and beverages, posing significant health risks such as lead poisoning and neurological damage. Lead-free glazes provide a safer alternative by eliminating these hazards, making them suitable for use in functional ceramics like dinnerware and cookware. Regulatory agencies worldwide restrict or ban leaded glazes in consumer products to protect public health and ensure safety.

Environmental Impact: Lead-Free Glaze Benefits

Lead-free glazes significantly reduce environmental contamination by eliminating toxic lead runoff during manufacturing and disposal processes. These glazes support safer waste management practices, preventing soil and water pollution linked to lead-based ceramics. Transitioning to lead-free options promotes sustainable ceramic production aligned with environmental health regulations.

Safety Standards for Ceramic Products

Lead-free glaze is preferred for ceramic products due to strict safety standards limiting lead content to prevent toxic exposure, especially in foodware. Regulatory agencies like the FDA and European Union enforce maximum allowable lead release levels, promoting lead-free formulations to ensure consumer safety. Leaded glazes, once common, pose significant health risks by leaching lead into food and beverages, making lead-free glazes the safer and compliant option for modern ceramics.

Performance Comparison: Durability and Appearance

Lead-free glazes offer enhanced durability by resisting crazing and chipping better than traditional leaded glazes, making them ideal for functional ceramics exposed to daily use. Leaded glazes, however, often provide a richer, more vibrant finish with superior translucency and depth of color, which many artists prefer for decorative pieces. The choice between lead-free and leaded glazes balances performance in longevity against aesthetic qualities, with lead-free options favored for safety and durability and leaded glazes prized for their visual appeal.

Regulations and Compliance in Glaze Composition

Lead-free glazes comply with stringent international safety standards, including the U.S. FDA and European Union regulations, ensuring non-toxicity in ceramic products intended for food use. Leaded glazes, historically common for their vibrant finishes, now face significant legal restrictions and bans due to lead's carcinogenic properties and potential for leaching. Manufacturers must rigorously test glaze compositions to meet regulatory limits on lead content, often below 0.1%, to guarantee consumer safety and market access.

Consumer Demand for Lead-Free Ceramics

Consumer demand for lead-free ceramics has surged due to increasing health and environmental concerns associated with leaded glaze. Lead-free glazes offer a safer alternative by eliminating toxic lead compounds, thereby reducing the risk of lead poisoning and contamination in food contact ceramics. This shift in consumer preference drives manufacturers to innovate and produce ceramics that meet stringent safety standards without compromising aesthetic quality.

Manufacturing Processes for Lead-Free Glazes

Manufacturing processes for lead-free glazes involve precise formulation adjustments to replace traditional lead compounds with non-toxic alternatives such as calcium, zinc, or boron oxides, ensuring safety without compromising durability or finish quality. These processes require controlled firing cycles and temperature calibrations to achieve optimal glaze adherence and surface smoothness while preventing defects like crazing or pinholing. Advanced techniques in raw material selection and mixing improve homogeneity, resulting in eco-friendly ceramic products that meet health regulations and industry standards.

Identifying Lead-Free vs Leaded Ceramics

Lead-free glazes are formulated with non-toxic materials such as silica, boron, and calcium, ensuring safe use in food-safe ceramics without risking lead contamination. Leaded glazes, often containing lead oxide, provide a lower melting point and vibrant color but pose health hazards due to lead leaching, especially in acidic foods. Identifying lead-free versus leaded ceramics involves examining product certifications like FDA approval, using lead test kits, and verifying manufacturer specifications to ensure safety compliance.

Future Trends in Safer Ceramic Glazing

Lead-free glaze technology is rapidly advancing, driven by stricter global regulations and increased consumer demand for non-toxic ceramics in food and drinkware. Innovations in alternative flux materials and improved firing processes enhance durability and aesthetic qualities without compromising safety. The future of ceramic glazing emphasizes sustainable and eco-friendly formulations, reducing environmental impact while maintaining high-performance standards.

Lead-Free Glaze vs Leaded Glaze Infographic

materialdif.com

materialdif.com