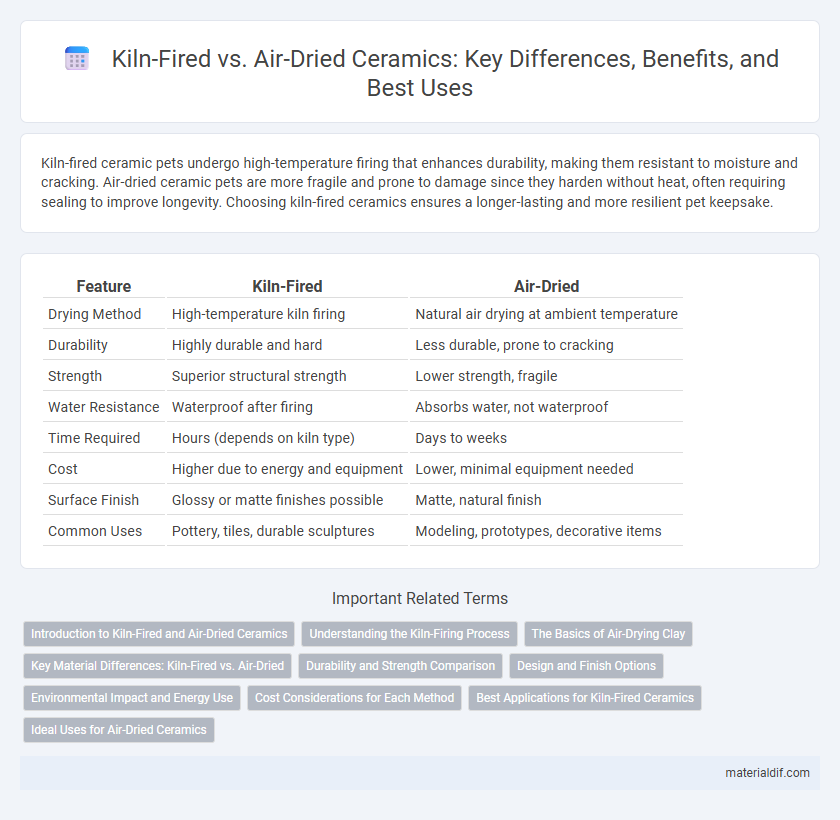

Kiln-fired ceramic pets undergo high-temperature firing that enhances durability, making them resistant to moisture and cracking. Air-dried ceramic pets are more fragile and prone to damage since they harden without heat, often requiring sealing to improve longevity. Choosing kiln-fired ceramics ensures a longer-lasting and more resilient pet keepsake.

Table of Comparison

| Feature | Kiln-Fired | Air-Dried |

|---|---|---|

| Drying Method | High-temperature kiln firing | Natural air drying at ambient temperature |

| Durability | Highly durable and hard | Less durable, prone to cracking |

| Strength | Superior structural strength | Lower strength, fragile |

| Water Resistance | Waterproof after firing | Absorbs water, not waterproof |

| Time Required | Hours (depends on kiln type) | Days to weeks |

| Cost | Higher due to energy and equipment | Lower, minimal equipment needed |

| Surface Finish | Glossy or matte finishes possible | Matte, natural finish |

| Common Uses | Pottery, tiles, durable sculptures | Modeling, prototypes, decorative items |

Introduction to Kiln-Fired and Air-Dried Ceramics

Kiln-fired ceramics undergo high-temperature firing in a controlled kiln environment, resulting in enhanced strength, durability, and water resistance compared to air-dried ceramics. Air-dried ceramics rely on natural evaporation to harden, making them suitable for lightweight, decorative pieces but more fragile and less water-resistant. Understanding the differences in firing methods is essential for selecting the appropriate ceramic type for various artistic and functional applications.

Understanding the Kiln-Firing Process

Kiln firing involves heating ceramic pieces to temperatures between approximately 1,000degC and 1,300degC, which vitrifies the clay, creating a dense, durable, and water-resistant material. This controlled, high-temperature process enhances the strength and longevity of ceramics compared to air-dried clay, which remains porous and fragile. The kiln firing process also enables glaze maturation, resulting in a smooth, finished surface that air-drying alone cannot achieve.

The Basics of Air-Drying Clay

Air-dried clay dries naturally through evaporation at room temperature without the need for a kiln, making it accessible for beginners and low-cost projects. It requires careful handling during the drying process to prevent cracking, as moisture escapes slowly and unevenly. While less durable than kiln-fired ceramics, air-dried clay is ideal for decorative pieces and lightweight sculptures that do not need to withstand high stress.

Key Material Differences: Kiln-Fired vs. Air-Dried

Kiln-fired ceramics undergo high-temperature firing that vitrifies the clay, resulting in increased strength, durability, and water resistance compared to air-dried ceramics, which harden through natural evaporation and retain a more porous, fragile structure. The intense heat in kiln firing causes chemical changes such as sintering and the formation of a glassy phase, enhancing the material's density and preventing decomposition over time. Air-dried clay remains prone to cracking and deformation due to its incomplete drying process and lower mechanical integrity.

Durability and Strength Comparison

Kiln-fired ceramics undergo high-temperature firing, resulting in increased density, enhanced strength, and superior durability compared to air-dried equivalents. Air-dried ceramics, cured at ambient temperatures, often exhibit weaker structural integrity and are more susceptible to cracking or moisture damage over time. The thermal vitrification process in kiln-firing produces a more resilient ceramic body, making it ideal for functional pottery and architectural applications.

Design and Finish Options

Kiln-fired ceramics offer a wider range of design and finish options due to the high temperatures that allow for durable glazes, intricate textures, and vibrant colors. Air-dried ceramics generally have a matte, porous surface with limited color vibrancy and are more prone to surface imperfections, restricting design versatility. Choosing kiln-fired methods enables artists to achieve a polished, professional finish with enhanced durability and complex decorative effects.

Environmental Impact and Energy Use

Kiln-fired ceramics require significant energy consumption, often relying on fossil fuels, which contributes to higher carbon emissions compared to air-dried ceramics. Air-dried ceramics eliminate the need for continuous energy input, reducing environmental impact and fossil fuel dependency. The choice between kiln-fired and air-dried methods directly affects overall energy efficiency and ecological footprint in ceramic production.

Cost Considerations for Each Method

Kiln-fired ceramics typically incur higher costs due to energy consumption and equipment maintenance, whereas air-dried ceramics save on energy but may require longer production times, impacting labor costs. Kiln-firing offers durability and uniformity that can reduce long-term expenses associated with product breakage or defects. Air-drying is economically viable for small-scale or artisanal projects but less practical for mass production due to variability and slower drying periods.

Best Applications for Kiln-Fired Ceramics

Kiln-fired ceramics offer exceptional durability, making them ideal for functional items like dinnerware, tiles, and architectural elements exposed to moisture and temperature changes. The high-temperature firing process enhances hardness and vitrification, ensuring resistance to wear and thermal shock. These properties make kiln-fired ceramics preferable for both artistic sculptures and industrial components requiring long-term structural integrity.

Ideal Uses for Air-Dried Ceramics

Air-dried ceramics are ideal for lightweight decorative pieces, prototypes, and non-functional art due to their ease of handling and absence of kiln requirements. This method suits porous sculptures and models that do not require high durability or water resistance. Artists working without access to kilns benefit from the reduced energy consumption and simplicity of air drying, making it perfect for home studios or educational projects.

Kiln-fired vs Air-dried Infographic

materialdif.com

materialdif.com