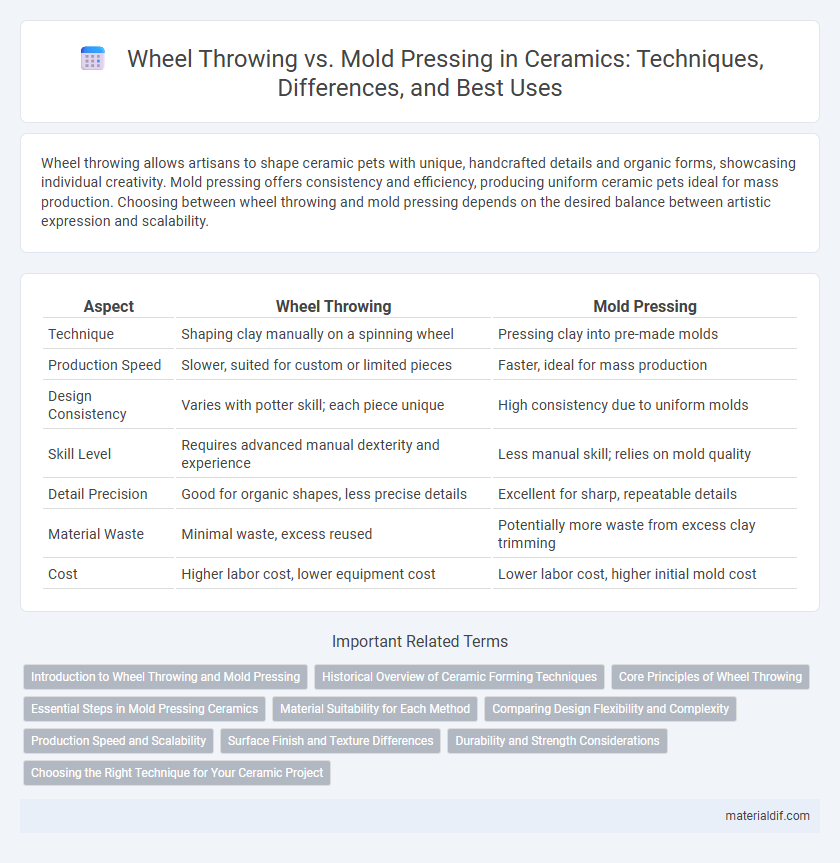

Wheel throwing allows artisans to shape ceramic pets with unique, handcrafted details and organic forms, showcasing individual creativity. Mold pressing offers consistency and efficiency, producing uniform ceramic pets ideal for mass production. Choosing between wheel throwing and mold pressing depends on the desired balance between artistic expression and scalability.

Table of Comparison

| Aspect | Wheel Throwing | Mold Pressing |

|---|---|---|

| Technique | Shaping clay manually on a spinning wheel | Pressing clay into pre-made molds |

| Production Speed | Slower, suited for custom or limited pieces | Faster, ideal for mass production |

| Design Consistency | Varies with potter skill; each piece unique | High consistency due to uniform molds |

| Skill Level | Requires advanced manual dexterity and experience | Less manual skill; relies on mold quality |

| Detail Precision | Good for organic shapes, less precise details | Excellent for sharp, repeatable details |

| Material Waste | Minimal waste, excess reused | Potentially more waste from excess clay trimming |

| Cost | Higher labor cost, lower equipment cost | Lower labor cost, higher initial mold cost |

Introduction to Wheel Throwing and Mold Pressing

Wheel throwing is a traditional ceramic technique where clay is shaped on a rotating pottery wheel, allowing for precise control and the creation of symmetrical, round forms like bowls and vases. Mold pressing involves pressing clay into pre-made molds, enabling consistent replication of complex shapes and detailed textures that are difficult to achieve by hand. Both methods are fundamental in ceramics, with wheel throwing emphasizing craftsmanship and mold pressing enhancing production efficiency.

Historical Overview of Ceramic Forming Techniques

Wheel throwing and mold pressing represent two distinct historical ceramic forming techniques that shaped artistic and functional pottery. Wheel throwing, traced back to ancient Mesopotamia around 3500 BCE, introduced rotational symmetry and allowed potters to create diverse shapes quickly by hand on a rotating wheel. Mold pressing emerged later, enabling mass production through replicable forms by pressing clay into pre-shaped molds, revolutionizing ceramic manufacturing during the Industrial Revolution.

Core Principles of Wheel Throwing

Wheel throwing centers on shaping clay by rotating it on a potter's wheel, enabling precise control over form and symmetry through hand movements. This technique relies fundamentally on centering the clay, opening the mass, and pulling the walls upward to create uniform thickness and balanced shapes. Mastery of these core principles allows artisans to produce unique, finely detailed ceramic pieces with organic variations impossible to achieve via mold pressing.

Essential Steps in Mold Pressing Ceramics

Mold pressing in ceramics involves preparing a liquid clay slip that is poured into plaster molds to form uniform shapes through capillary action, followed by a drying phase that solidifies the form. The essential steps include slip preparation, mold filling, initial setting time allowing moisture absorption, carefully extracting the greenware from the mold, and controlled drying to prevent warping. This process contrasts wheel throwing by enabling mass production of consistent ceramic pieces with intricate details replicated from the mold design.

Material Suitability for Each Method

Wheel throwing excels with clay bodies that have plasticity and workability, such as stoneware and porcelain, allowing precise shaping through rotational motion. Mold pressing suits softer, more slip-like clay mixtures or earthenware that can flow easily into detailed molds, enabling consistent replication of complex forms. Choosing the right method depends on clay composition: high-plasticity clays favor wheel throwing, while less plastic, more fluid materials are ideal for mold pressing.

Comparing Design Flexibility and Complexity

Wheel throwing offers greater design flexibility by allowing continuous shaping and modification of ceramic pieces directly on the wheel, enabling unique, organic forms and intricate textures. Mold pressing delivers consistent results with complex, repeatable shapes but limits variation and spontaneity due to its reliance on pre-made molds. Designers seeking bespoke, complex forms often prefer wheel throwing, while production-focused workflows benefit from the uniformity of mold pressing.

Production Speed and Scalability

Wheel throwing allows for unique, handcrafted ceramic pieces but has slower production speed and limited scalability compared to mold pressing. Mold pressing significantly accelerates production by enabling consistent replication of designs, making it ideal for large-scale manufacturing. High-volume ceramic production benefits from mold pressing due to its efficiency and uniformity, while wheel throwing suits small-batch, artisanal creations.

Surface Finish and Texture Differences

Wheel throwing produces ceramics with subtle, organic ridges and variations due to the potter's hand movements, resulting in a tactile, handcrafted surface finish. Mold pressing creates pieces with a consistently smooth, uniform texture, as the clay conforms precisely to the mold's contours. These surface finish differences impact the visual appeal and tactile experience, with wheel throwing often preferred for unique, artisanal textures and mold pressing for mass-produced, flawless ceramics.

Durability and Strength Considerations

Wheel throwing produces ceramics with a denser, more uniform structure due to the compressive forces applied during shaping, resulting in enhanced durability and strength. Mold pressing can lead to variations in thickness and potential air pockets, which may compromise the ceramic's mechanical integrity under stress. For applications requiring high structural resilience, wheel-thrown pieces generally outperform mold-pressed ceramics in terms of resistance to cracking and impact.

Choosing the Right Technique for Your Ceramic Project

Wheel throwing offers greater control and individuality, ideal for creating symmetrical, rounded shapes like bowls and vases, while mold pressing excels at producing consistent, complex forms with detailed textures efficiently. Consider the project scale and design complexity; wheel throwing suits custom, one-of-a-kind pieces, whereas mold pressing benefits mass production and uniformity. Material type and desired finish also influence the choice, as wheel throwing works well with soft clay bodies and organic shapes, and mold pressing adapts to firm clays with intricate surface patterns.

Wheel Throwing vs Mold Pressing Infographic

materialdif.com

materialdif.com