Kiln firing offers precise temperature control and consistent heat distribution, resulting in durable, high-quality ceramic pet items with reduced risk of cracking or warping. Open firing exposes ceramics to unpredictable conditions and contaminants, often causing uneven hardness and surface imperfections. For pet-related ceramics, kiln firing ensures safer, non-toxic finishes ideal for items like bowls and figurines.

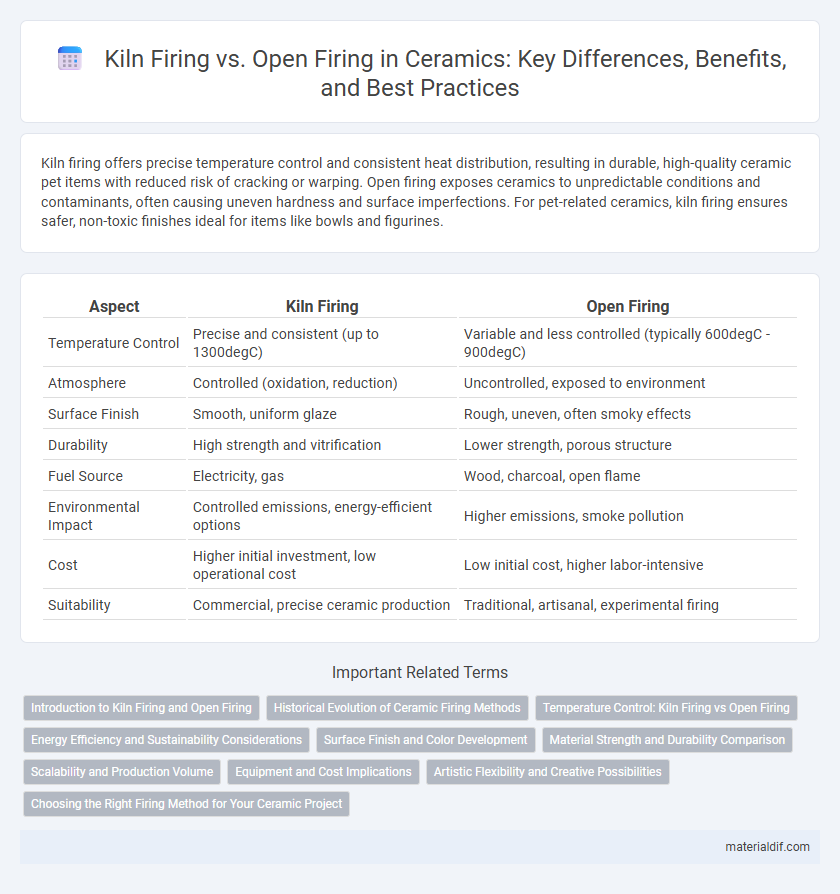

Table of Comparison

| Aspect | Kiln Firing | Open Firing |

|---|---|---|

| Temperature Control | Precise and consistent (up to 1300degC) | Variable and less controlled (typically 600degC - 900degC) |

| Atmosphere | Controlled (oxidation, reduction) | Uncontrolled, exposed to environment |

| Surface Finish | Smooth, uniform glaze | Rough, uneven, often smoky effects |

| Durability | High strength and vitrification | Lower strength, porous structure |

| Fuel Source | Electricity, gas | Wood, charcoal, open flame |

| Environmental Impact | Controlled emissions, energy-efficient options | Higher emissions, smoke pollution |

| Cost | Higher initial investment, low operational cost | Low initial cost, higher labor-intensive |

| Suitability | Commercial, precise ceramic production | Traditional, artisanal, experimental firing |

Introduction to Kiln Firing and Open Firing

Kiln firing involves heating ceramics in a controlled, enclosed environment that reaches high temperatures necessary for vitrification and durability. Open firing exposes ceramics to an open flame or smoke, often resulting in lower temperatures and unique surface effects such as smoky or pit-fired textures. The choice between kiln and open firing affects the strength, finish, and overall quality of the ceramic piece.

Historical Evolution of Ceramic Firing Methods

Kiln firing revolutionized ceramic production by enabling higher, more controlled temperatures, resulting in durable, vitrified pottery compared to the earlier open firing technique that relied on variable heat and smoke exposure. Archaeological findings trace open firing to prehistoric times, while kiln technology emerged around 6000 BCE in ancient China and Mesopotamia, marking significant advancements in ceramic craftsmanship. The historical evolution from open firing to kiln firing reflects humanity's growing mastery of thermal processes, directly influencing ceramic quality, aesthetic complexity, and cultural significance.

Temperature Control: Kiln Firing vs Open Firing

Kiln firing offers precise temperature control, maintaining consistent heat levels crucial for achieving durable and uniformly vitrified ceramics. Open firing relies on fluctuating temperatures influenced by environmental factors, resulting in less predictable outcomes and potential structural weaknesses. Accurate temperature regulation in kiln firing enhances glaze development and reduces the risk of cracking compared to the variable heat of open firing.

Energy Efficiency and Sustainability Considerations

Kiln firing offers superior energy efficiency due to controlled temperature settings and insulation, significantly reducing fuel consumption compared to open firing methods. Open firing typically results in higher emissions and fuel waste, making it less sustainable for large-scale or continuous ceramic production. Advances in kiln technology further enhance sustainability by incorporating electric or solar-powered options, minimizing the environmental impact of ceramic firing processes.

Surface Finish and Color Development

Kiln firing produces a more controlled and uniform surface finish with enhanced color development due to precise temperature regulation and atmospheric conditions, allowing for richer and more vibrant glaze effects. Open firing exposes ceramics to unpredictable elements, often resulting in varied surface textures and more muted or rustic color tones due to uneven heat and smoke interaction. The choice between kiln and open firing significantly influences the final aesthetic quality, surface durability, and color saturation of ceramic pieces.

Material Strength and Durability Comparison

Kiln firing achieves higher temperatures (up to 1300degC) providing ceramic materials with superior vitrification, resulting in increased strength and durability compared to open firing, which typically reaches lower temperatures around 600-800degC. The controlled atmosphere in kiln firing reduces porosity and enhances the ceramic's resistance to chipping and cracking, whereas open firing produces more porous, less structurally sound ceramics prone to faster wear. Material density and uniform heat distribution in kiln firing contribute to ceramics with enhanced mechanical properties and longer lifespan.

Scalability and Production Volume

Kiln firing offers precise temperature control and consistent heat distribution, making it highly scalable for large production volumes in ceramic manufacturing. Open firing lacks uniform heat, resulting in variable product quality and limited batch sizes, which constrain scalability. Industrial-scale ceramic production favors kiln firing due to its ability to maintain consistent quality across extensive batches.

Equipment and Cost Implications

Kiln firing utilizes specialized refractory materials and electric, gas, or wood-fueled kilns that allow precise temperature control, resulting in consistent ceramic quality but requiring significant initial investment and operational costs. Open firing relies on accessible materials such as wood or charcoal and simple pit or bonfire setups, minimizing equipment expenses but sacrificing temperature regulation and uniformity. The choice between kiln and open firing drives cost implications primarily through equipment durability, fuel efficiency, and ceramic outcome reliability.

Artistic Flexibility and Creative Possibilities

Kiln firing offers precise temperature control and atmosphere regulation, enabling artists to achieve a wide range of finishes, glazes, and complex textures. Open firing, by contrast, provides unpredictable results that encourage spontaneity and organic surface variations, which many artists find appealing for experimental and rustic aesthetics. The choice between kiln firing and open firing significantly influences creative possibilities, with kiln firing suited for detailed and consistent outcomes while open firing fosters unique, one-of-a-kind expressions.

Choosing the Right Firing Method for Your Ceramic Project

Kiln firing offers precise temperature control essential for achieving durability and consistent glaze results in ceramic projects, while open firing provides a traditional, organic finish with unique surface textures influenced by natural elements. Selecting the right firing method depends on the desired aesthetic, material composition, and project scale, with kiln firing suitable for high-fired stoneware and porcelain, and open firing ideal for low-fire earthenware and experimental styles. Considering factors such as temperature range, atmosphere control, and firing duration ensures optimal outcomes aligned with artistic intentions and functional requirements.

Kiln Firing vs Open Firing Infographic

materialdif.com

materialdif.com