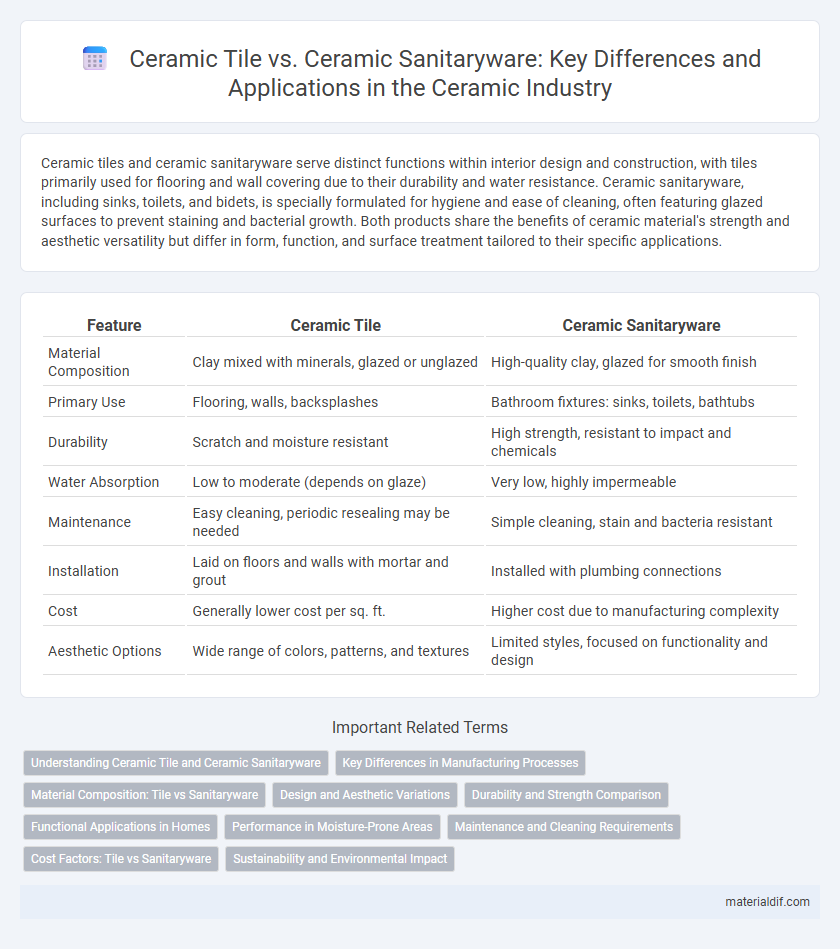

Ceramic tiles and ceramic sanitaryware serve distinct functions within interior design and construction, with tiles primarily used for flooring and wall covering due to their durability and water resistance. Ceramic sanitaryware, including sinks, toilets, and bidets, is specially formulated for hygiene and ease of cleaning, often featuring glazed surfaces to prevent staining and bacterial growth. Both products share the benefits of ceramic material's strength and aesthetic versatility but differ in form, function, and surface treatment tailored to their specific applications.

Table of Comparison

| Feature | Ceramic Tile | Ceramic Sanitaryware |

|---|---|---|

| Material Composition | Clay mixed with minerals, glazed or unglazed | High-quality clay, glazed for smooth finish |

| Primary Use | Flooring, walls, backsplashes | Bathroom fixtures: sinks, toilets, bathtubs |

| Durability | Scratch and moisture resistant | High strength, resistant to impact and chemicals |

| Water Absorption | Low to moderate (depends on glaze) | Very low, highly impermeable |

| Maintenance | Easy cleaning, periodic resealing may be needed | Simple cleaning, stain and bacteria resistant |

| Installation | Laid on floors and walls with mortar and grout | Installed with plumbing connections |

| Cost | Generally lower cost per sq. ft. | Higher cost due to manufacturing complexity |

| Aesthetic Options | Wide range of colors, patterns, and textures | Limited styles, focused on functionality and design |

Understanding Ceramic Tile and Ceramic Sanitaryware

Ceramic tiles are primarily manufactured for flooring, wall coverings, and decorative purposes, featuring glazed or unglazed surfaces tailored for durability and aesthetic appeal. Ceramic sanitaryware includes bathroom fixtures such as sinks, toilets, and bidets, specifically designed to resist water, stains, and bacteria while providing comfort and hygiene. Both products utilize fired clay but differ in formulation, glazing techniques, and functional requirements essential for their respective applications.

Key Differences in Manufacturing Processes

Ceramic tile manufacturing involves shaping clay into thin slabs, followed by glazing and high-temperature kiln firing to achieve a durable, decorative surface. In contrast, ceramic sanitaryware production requires molding clay into complex shapes like sinks or toilets, with multiple firings including bisque and glaze firing to ensure strength and water resistance. The key differences lie in the molding techniques and firing cycles tailored to each product's functional and aesthetic requirements.

Material Composition: Tile vs Sanitaryware

Ceramic tiles are primarily made from a mixture of clay, quartz, and feldspar fired at high temperatures to achieve hardness and durability, with a dense, glazed surface for moisture resistance. Ceramic sanitaryware, including sinks and toilets, uses refined white clay (kaolin) combined with feldspar and quartz, then glazed and fired at higher temperatures to create a dense, non-porous, and hygienic surface. The material composition differences result in tiles emphasizing durability and design flexibility, while sanitaryware focuses on smoothness, impermeability, and resistance to chemical wear.

Design and Aesthetic Variations

Ceramic tiles offer a vast spectrum of design possibilities, including intricate patterns, vibrant colors, and diverse textures that enhance flooring and wall aesthetics. In contrast, ceramic sanitaryware emphasizes smooth, sleek forms with minimalistic designs tailored for functionality and modern bathroom elegance. The difference in surface finish and design intricacy caters to distinct aesthetic requirements in interior decor and sanitary applications.

Durability and Strength Comparison

Ceramic tiles exhibit high durability and resistance to wear, making them ideal for floors and walls in high-traffic areas, while ceramic sanitaryware is engineered for structural strength and impact resistance to withstand daily use and water exposure in bathrooms. Tiles typically have a lower porosity and are coated with a glaze that enhances scratch resistance and longevity, whereas sanitaryware undergoes vitrification processes that increase density and reduce susceptibility to chipping or cracking. The manufacturing techniques for sanitaryware prioritize compressive strength and smoothness, ensuring both functional performance and aesthetic durability compared to the relatively flat and brittle nature of ceramic tiles.

Functional Applications in Homes

Ceramic tiles provide durable, water-resistant surfaces ideal for flooring and wall coverings in kitchens, bathrooms, and living areas, enhancing both functionality and aesthetic appeal. Ceramic sanitaryware, including sinks, toilets, and bidets, ensures hygiene and ease of cleaning through non-porous, glazed finishes that resist stains and odors. Both materials leverage ceramic's strength and moisture resistance, but tiles primarily address surface protection, while sanitaryware focuses on essential bathroom utilities.

Performance in Moisture-Prone Areas

Ceramic tiles exhibit high resistance to water absorption, making them ideal for moisture-prone areas such as bathrooms and kitchens by preventing mold and mildew growth. Ceramic sanitaryware, including sinks and toilets, is engineered with a dense, non-porous glaze that enhances durability and hygiene under constant water exposure. Both materials maintain structural integrity and aesthetic appeal in humid environments, but ceramic tiles offer greater versatility in water-resistant surface applications.

Maintenance and Cleaning Requirements

Ceramic tiles require regular sweeping and mopping with a mild detergent to prevent dirt buildup and maintain their glossy finish, while grout lines need occasional scrubbing to avoid mold and stains. Ceramic sanitaryware demands frequent cleaning with non-abrasive cleaners to prevent limescale, soap scum, and bacterial growth, especially around faucets and drains. Both materials benefit from sealing treatments to enhance durability and resistance against stains, minimizing long-term maintenance efforts.

Cost Factors: Tile vs Sanitaryware

Ceramic tiles generally have a lower cost per square foot compared to ceramic sanitaryware due to differences in manufacturing processes and material complexity. Installation expenses for ceramic sanitaryware, which includes items like sinks and toilets, tend to be higher because of plumbing requirements and specialized labor. Maintenance costs also vary, with ceramic sanitaryware often requiring more frequent repairs or replacements, impacting the overall lifecycle cost.

Sustainability and Environmental Impact

Ceramic tiles generally have a lower environmental impact during production, as they require less energy and raw materials compared to ceramic sanitaryware, which involves more complex manufacturing processes and higher water consumption. Tiles contribute to sustainable construction by offering durability, low maintenance, and recyclability, reducing waste over time. In contrast, ceramic sanitaryware, while essential for hygiene, often results in higher carbon emissions and resource usage, making eco-friendly innovations in glaze formulations and water-saving technologies critical for reducing its environmental footprint.

Ceramic Tile vs Ceramic Sanitaryware Infographic

materialdif.com

materialdif.com