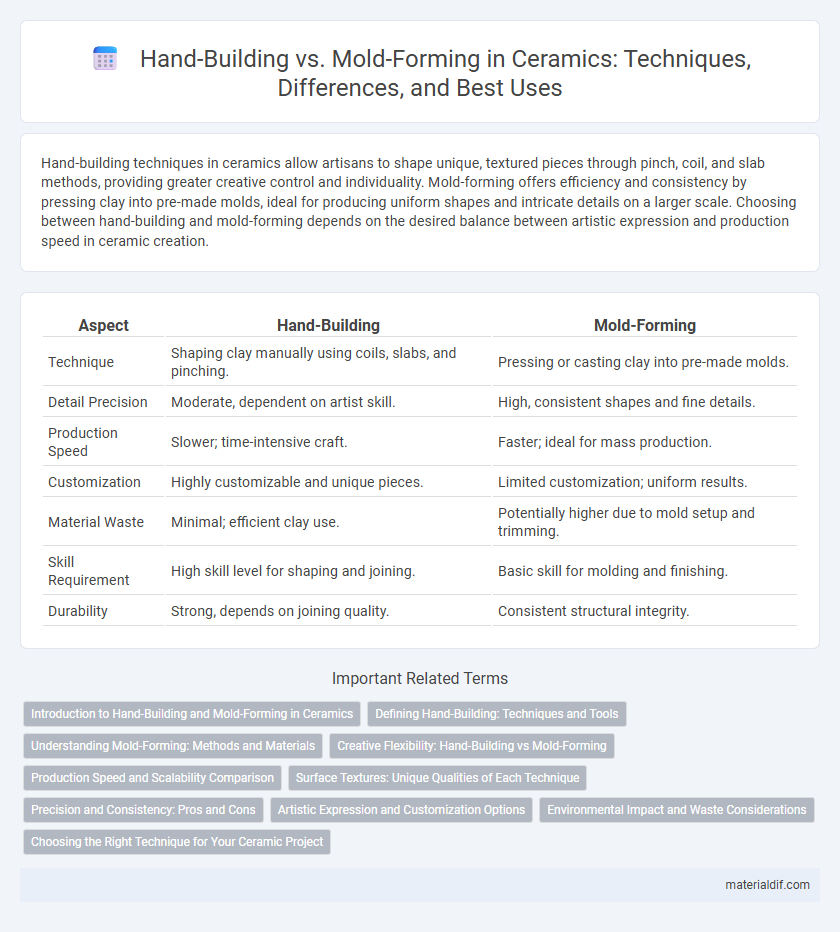

Hand-building techniques in ceramics allow artisans to shape unique, textured pieces through pinch, coil, and slab methods, providing greater creative control and individuality. Mold-forming offers efficiency and consistency by pressing clay into pre-made molds, ideal for producing uniform shapes and intricate details on a larger scale. Choosing between hand-building and mold-forming depends on the desired balance between artistic expression and production speed in ceramic creation.

Table of Comparison

| Aspect | Hand-Building | Mold-Forming |

|---|---|---|

| Technique | Shaping clay manually using coils, slabs, and pinching. | Pressing or casting clay into pre-made molds. |

| Detail Precision | Moderate, dependent on artist skill. | High, consistent shapes and fine details. |

| Production Speed | Slower; time-intensive craft. | Faster; ideal for mass production. |

| Customization | Highly customizable and unique pieces. | Limited customization; uniform results. |

| Material Waste | Minimal; efficient clay use. | Potentially higher due to mold setup and trimming. |

| Skill Requirement | High skill level for shaping and joining. | Basic skill for molding and finishing. |

| Durability | Strong, depends on joining quality. | Consistent structural integrity. |

Introduction to Hand-Building and Mold-Forming in Ceramics

Hand-building in ceramics involves creating forms directly by shaping clay using techniques like pinching, coiling, and slab construction, allowing for unique, organic shapes and detailed textures. Mold-forming uses pre-made molds to shape clay, enabling consistent and repeatable designs, ideal for mass production or intricate patterns. Both methods offer distinct advantages: hand-building prioritizes artistic expression and customization, while mold-forming ensures precision and efficiency in ceramic creation.

Defining Hand-Building: Techniques and Tools

Hand-building in ceramics involves shaping clay using techniques such as pinch, coil, and slab methods without the use of a potter's wheel. Essential tools include wire cutters, ribs, modeling tools, and sponges that aid in refining forms and textures. This manual approach allows for greater artistic flexibility and unique, organic shapes compared to mold-forming methods.

Understanding Mold-Forming: Methods and Materials

Mold-forming in ceramics involves shaping clay using pre-made molds crafted from materials like plaster, wood, or resin, allowing for consistent replication of complex designs. Common methods include press molding, slip casting, and hump molding, each suited to different types of clay and desired detail levels. Choosing the right mold material and method enhances precision, efficiency, and texture control in ceramic production.

Creative Flexibility: Hand-Building vs Mold-Forming

Hand-building offers unmatched creative flexibility, allowing artists to shape unique, organic forms with personalized textures and details. Mold-forming provides consistency and efficiency but limits individual expression due to its reliance on predefined shapes. For ceramic artists seeking artistic freedom and customized design, hand-building remains the preferred technique.

Production Speed and Scalability Comparison

Hand-building in ceramics offers unparalleled creative flexibility but is significantly slower and less scalable compared to mold-forming techniques, which enable rapid and consistent production of large quantities. Mold-forming, utilizing plaster or silicone molds, accelerates production speed by allowing multiple replicas to be formed simultaneously, making it ideal for commercial manufacturing. While hand-building is optimal for unique, artisanal pieces, mold-forming excels in scalability, reducing labor intensity and improving efficiency in mass production settings.

Surface Textures: Unique Qualities of Each Technique

Hand-building techniques in ceramics often produce organic, tactile surface textures characterized by subtle irregularities and impressions that reflect the artist's direct interaction with the clay. Mold-forming, in contrast, yields surfaces with more uniform and precise textures, allowing for intricate patterns and consistent repetition that are difficult to achieve by hand. Both methods enable diverse aesthetic outcomes, with hand-building celebrated for its expressive, one-of-a-kind textures, and mold-forming prized for its ability to replicate detailed, smooth finishes efficiently.

Precision and Consistency: Pros and Cons

Hand-building in ceramics offers unique creative control and organic shapes but often lacks precision and consistency compared to mold-forming. Mold-forming enables mass production with uniform dimensions and intricate details, ensuring high consistency across pieces. However, it limits individual artistic variation and can require significant initial investment in mold creation.

Artistic Expression and Customization Options

Hand-building techniques in ceramics offer unparalleled artistic expression by allowing artisans to shape unique, intricate forms directly with their hands, fostering individual creativity and tactile connection to the material. Mold-forming, while efficient for producing consistent shapes, limits customization but enables replication of detailed designs, making it ideal for uniform collections or mass production. Choosing between hand-building and mold-forming hinges on the desired balance between personalized artistic freedom and reproducibility in ceramic creation.

Environmental Impact and Waste Considerations

Hand-building techniques in ceramics produce minimal waste by using natural materials more efficiently and allowing scraps to be reworked, reducing landfill contributions. Mold-forming often involves synthetic molds and generates more offcuts and excess slip, leading to greater environmental burden through production and disposal processes. Choosing hand-building supports sustainable practices by lowering energy consumption and minimizing the ecological footprint associated with ceramic creation.

Choosing the Right Technique for Your Ceramic Project

Hand-building offers unparalleled creative freedom and tactile control, ideal for unique, organic shapes and detailed textural work in ceramic projects. Mold-forming excels in producing consistent, repeatable pieces with smooth surfaces, making it perfect for mass production or standardized designs. Selecting the right technique depends on the project's scale, desired finish, and complexity, balancing artistic expression with efficiency.

Hand-Building vs Mold-Forming Infographic

materialdif.com

materialdif.com