Dense ceramic exhibits high strength, low porosity, and excellent resistance to wear and corrosion, making it ideal for structural and high-performance applications. Porous ceramic features interconnected voids allowing fluid or gas permeability, which is beneficial in filtration, insulation, and catalyst support. Selecting between dense and porous ceramic depends on the required mechanical properties and functional performance in specific industrial uses.

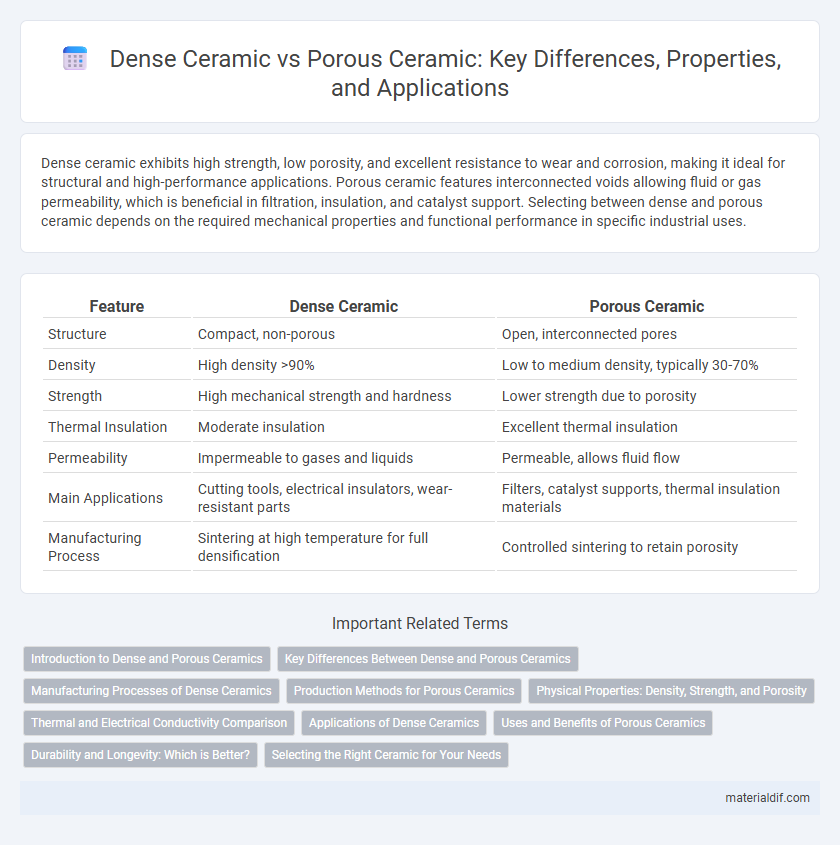

Table of Comparison

| Feature | Dense Ceramic | Porous Ceramic |

|---|---|---|

| Structure | Compact, non-porous | Open, interconnected pores |

| Density | High density >90% | Low to medium density, typically 30-70% |

| Strength | High mechanical strength and hardness | Lower strength due to porosity |

| Thermal Insulation | Moderate insulation | Excellent thermal insulation |

| Permeability | Impermeable to gases and liquids | Permeable, allows fluid flow |

| Main Applications | Cutting tools, electrical insulators, wear-resistant parts | Filters, catalyst supports, thermal insulation materials |

| Manufacturing Process | Sintering at high temperature for full densification | Controlled sintering to retain porosity |

Introduction to Dense and Porous Ceramics

Dense ceramics exhibit a tightly packed microstructure with minimal porosity, resulting in high mechanical strength and enhanced resistance to wear and corrosion. Porous ceramics contain interconnected voids or pores, offering benefits such as low density, thermal insulation, and permeability for applications like filtration and biomedical implants. Understanding the differences in porosity and microstructural characteristics is crucial for selecting the appropriate ceramic type for specific industrial or technological uses.

Key Differences Between Dense and Porous Ceramics

Dense ceramics exhibit low porosity, resulting in high strength, excellent wear resistance, and superior thermal and electrical insulation properties. Porous ceramics, characterized by interconnected voids, offer enhanced permeability, lightweight structures, and good thermal shock resistance, making them ideal for filtration and thermal insulation applications. The key differences revolve around density, mechanical strength, and functional performance tailored to specific industrial needs.

Manufacturing Processes of Dense Ceramics

Manufacturing dense ceramics typically involves powder processing techniques such as pressing, casting, and sintering under high pressure and temperature to achieve low porosity and high mechanical strength. Techniques like hot isostatic pressing (HIP) and spark plasma sintering (SPS) enhance densification by reducing grain boundaries and eliminating voids. Dense ceramics are favored in applications requiring superior hardness, wear resistance, and thermal stability due to their minimal porosity and refined microstructure.

Production Methods for Porous Ceramics

Porous ceramics are commonly produced using methods such as sacrificial templating, freeze casting, and partial sintering, which create controlled pore structures to enhance properties like filtration and thermal insulation. Sacrificial templating involves embedding and later removing organic or polymeric particles to form interconnected pores, while freeze casting uses the directional solidification of a solvent to align pores during sublimation. Partial sintering heats ceramic powders just below full densification, leaving intentional voids that contribute to the porosity essential for applications in catalyst supports and lightweight components.

Physical Properties: Density, Strength, and Porosity

Dense ceramics exhibit high density, typically above 95% of their theoretical density, resulting in superior mechanical strength and low porosity under 5%. Porous ceramics, with densities significantly lower due to intentional void spaces, offer reduced strength but enhanced thermal insulation and filtration capabilities. The contrast in physical properties impacts their application range, where dense ceramics suit structural uses and porous ceramics excel in environments requiring gas or fluid permeability.

Thermal and Electrical Conductivity Comparison

Dense ceramic materials exhibit higher thermal and electrical conductivity due to their compact microstructure, which facilitates efficient heat and electron transfer. Porous ceramics possess lower conductivity as air pockets within the material interrupt heat flow and electron movement, significantly enhancing thermal insulation properties. The contrasting conductivity traits make dense ceramics ideal for applications requiring rapid heat dissipation, while porous ceramics excel in insulating environments.

Applications of Dense Ceramics

Dense ceramics exhibit high mechanical strength, wear resistance, and chemical inertness, making them ideal for applications in cutting tools, biomedical implants, and electronic substrates. Their low porosity ensures exceptional thermal and electrical insulation properties, widely utilized in aerospace components and sensor technologies. Dense ceramics are also preferred for corrosion-resistant coatings and structural components in harsh environments where durability is critical.

Uses and Benefits of Porous Ceramics

Porous ceramics are extensively used in filtration systems, catalyst supports, and biomedical implants due to their high surface area and permeability. Their interconnected pore structure offers excellent gas and liquid flow, enhancing applications in water purification, air filtration, and tissue engineering. Unlike dense ceramics, porous ceramics provide lightweight solutions with superior thermal insulation and shock absorption properties.

Durability and Longevity: Which is Better?

Dense ceramic exhibits superior durability and longevity compared to porous ceramic due to its reduced pore size and higher mechanical strength, which resist wear and environmental degradation more effectively. Porous ceramic, while beneficial for applications requiring permeability or insulation, is more susceptible to cracking and moisture absorption, leading to compromised structural integrity over time. The enhanced toughness and lower water absorption rate of dense ceramic make it the preferred choice for long-lasting, high-performance ceramic products.

Selecting the Right Ceramic for Your Needs

Dense ceramics offer high mechanical strength, low porosity, and excellent resistance to wear and corrosion, making them ideal for structural and load-bearing applications. Porous ceramics provide superior thermal insulation, filtration capabilities, and lightweight properties, suited for applications requiring permeability or cushioning. Selecting the right ceramic depends on balancing required mechanical performance, thermal behavior, and permeability to optimize functionality for your specific needs.

Dense Ceramic vs Porous Ceramic Infographic

materialdif.com

materialdif.com