Slip casting offers precise replication of intricate ceramic forms by pouring liquid clay into molds, ensuring uniformity and consistency in production. Hand building allows greater artistic expression through techniques like pinching, coiling, and slab construction, making each piece unique and textured. Both methods have distinct advantages depending on whether uniformity or individuality in ceramic art is the goal.

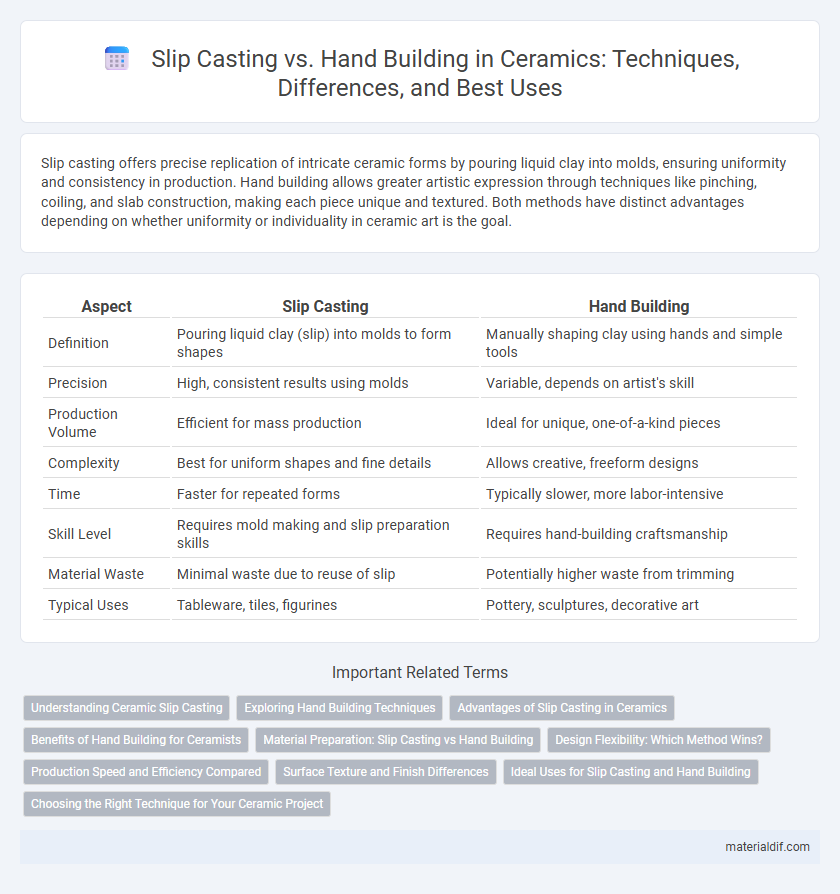

Table of Comparison

| Aspect | Slip Casting | Hand Building |

|---|---|---|

| Definition | Pouring liquid clay (slip) into molds to form shapes | Manually shaping clay using hands and simple tools |

| Precision | High, consistent results using molds | Variable, depends on artist's skill |

| Production Volume | Efficient for mass production | Ideal for unique, one-of-a-kind pieces |

| Complexity | Best for uniform shapes and fine details | Allows creative, freeform designs |

| Time | Faster for repeated forms | Typically slower, more labor-intensive |

| Skill Level | Requires mold making and slip preparation skills | Requires hand-building craftsmanship |

| Material Waste | Minimal waste due to reuse of slip | Potentially higher waste from trimming |

| Typical Uses | Tableware, tiles, figurines | Pottery, sculptures, decorative art |

Understanding Ceramic Slip Casting

Ceramic slip casting involves pouring liquid clay, known as slip, into plaster molds where water is absorbed, allowing the clay to solidify into detailed shapes with smooth surfaces. This technique excels at producing uniform, intricate forms ideal for mass production, unlike hand building which relies on manual shaping and coiling, resulting in more unique, textured pieces. Mastery of slip viscosity and mold design is essential for successful casting, ensuring consistent wall thickness and defect-free ceramics.

Exploring Hand Building Techniques

Hand building techniques in ceramics, including pinching, coiling, and slab construction, offer artists greater creative freedom and tactile control compared to slip casting. These methods allow for the creation of unique, organic shapes and textures that are difficult to achieve with molds. Mastery of hand building enhances the ability to produce customized, one-of-a-kind ceramic pieces with a personal artistic touch.

Advantages of Slip Casting in Ceramics

Slip casting offers precise replication of intricate ceramic designs, making it ideal for mass production with consistent quality. This method reduces labor intensity compared to hand building, enabling efficient volume creation with minimal material waste. The ability to produce thin, delicate forms that are difficult to achieve by hand enhances both aesthetic and functional versatility in ceramic manufacturing.

Benefits of Hand Building for Ceramists

Hand building offers ceramists exceptional creative freedom by allowing precise control over form and texture without the constraints of molds. This method enhances the artist's tactile connection to the clay, fostering unique, one-of-a-kind ceramic pieces. Moreover, hand building efficiently supports small-scale and intricate designs, making it ideal for experimental techniques and personalized artistry.

Material Preparation: Slip Casting vs Hand Building

Slip casting requires the preparation of a fluid, pourable slip made by mixing fine clay particles with water to achieve a smooth consistency for mold filling. Hand building utilizes more plastic clay, which is wedged to remove air bubbles and ensure even moisture content for optimal shaping by hand. Proper material preparation impacts the durability and surface finish of the final ceramic piece in both techniques.

Design Flexibility: Which Method Wins?

Slip casting excels in replicating intricate and consistent designs through molds, offering high precision for complex shapes, while hand building provides unmatched flexibility for unique, organic forms and expressive textures. Designers seeking uniformity and mass production often prefer slip casting, whereas artists favor hand building for creative experimentation and one-of-a-kind pieces. Choosing between the two depends on whether precision or artistic freedom takes precedence in the ceramic project.

Production Speed and Efficiency Compared

Slip casting offers faster production speeds due to its ability to rapidly reproduce complex shapes with minimal manual labor, making it highly efficient for mass production. Hand building, although versatile and allowing for unique, artisanal details, is significantly slower and less efficient because each piece requires individual shaping and longer drying times. Manufacturers prioritize slip casting when high volume output and consistent quality are crucial, while hand building suits custom or limited edition works where speed is less critical.

Surface Texture and Finish Differences

Slip casting produces smooth, uniform surfaces due to liquid clay poured into molds, resulting in fine, consistent textures ideal for detailed designs. Hand building allows for more tactile, varied surfaces as artists shape the clay manually, often leaving visible marks or intentional textures that enhance the piece's character. The finish in slip casting is typically polished and refined, while hand building embraces organic, textured finishes that emphasize craftsmanship.

Ideal Uses for Slip Casting and Hand Building

Slip casting is ideal for producing complex, detailed, and uniform ceramic pieces in large quantities, making it perfect for industrial production and intricate molds. Hand building excels in creating unique, one-of-a-kind artworks or functional pottery with organic shapes and textures, allowing greater creative freedom and personalization. Each method serves different artistic and production goals, with slip casting favoring precision and replication, while hand building emphasizes craftsmanship and individuality.

Choosing the Right Technique for Your Ceramic Project

Slip casting offers precision and uniformity by pouring liquid clay into molds, ideal for intricate shapes and mass production, while hand building allows for greater artistic expression and uniqueness through methods like pinching, coiling, and slab construction. Selecting the right technique depends on the project's complexity, desired texture, and production volume, with slip casting suited for repeatability and hand building favored for one-of-a-kind pieces. Understanding the material properties and end-use of the ceramic work ensures optimal technique choice, enhancing durability and aesthetic appeal.

Slip Casting vs Hand Building Infographic

materialdif.com

materialdif.com