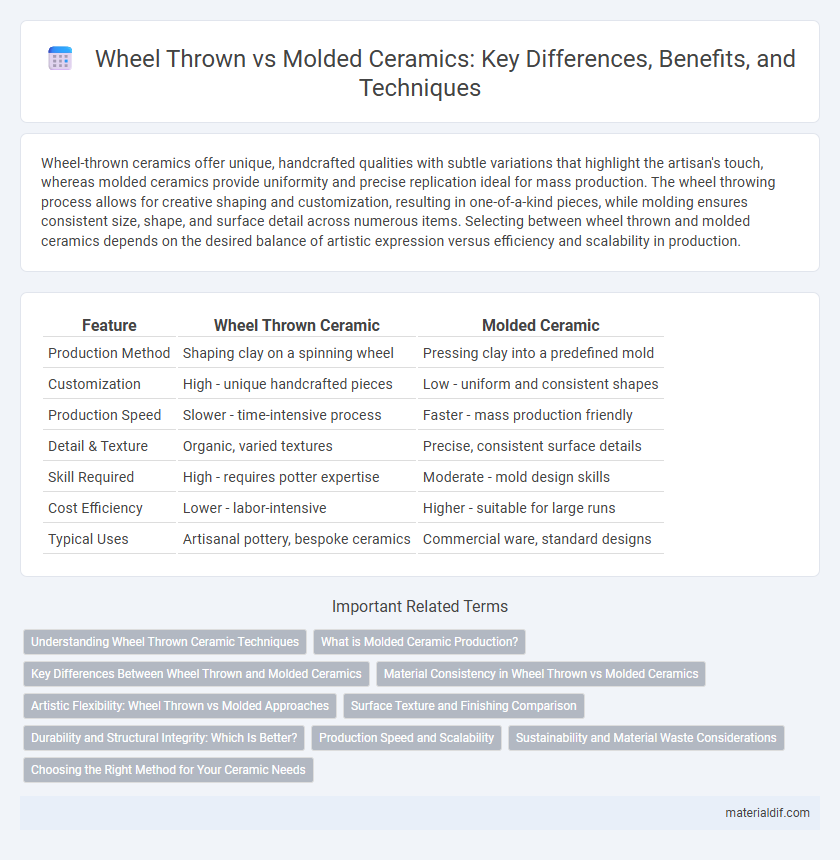

Wheel-thrown ceramics offer unique, handcrafted qualities with subtle variations that highlight the artisan's touch, whereas molded ceramics provide uniformity and precise replication ideal for mass production. The wheel throwing process allows for creative shaping and customization, resulting in one-of-a-kind pieces, while molding ensures consistent size, shape, and surface detail across numerous items. Selecting between wheel thrown and molded ceramics depends on the desired balance of artistic expression versus efficiency and scalability in production.

Table of Comparison

| Feature | Wheel Thrown Ceramic | Molded Ceramic |

|---|---|---|

| Production Method | Shaping clay on a spinning wheel | Pressing clay into a predefined mold |

| Customization | High - unique handcrafted pieces | Low - uniform and consistent shapes |

| Production Speed | Slower - time-intensive process | Faster - mass production friendly |

| Detail & Texture | Organic, varied textures | Precise, consistent surface details |

| Skill Required | High - requires potter expertise | Moderate - mold design skills |

| Cost Efficiency | Lower - labor-intensive | Higher - suitable for large runs |

| Typical Uses | Artisanal pottery, bespoke ceramics | Commercial ware, standard designs |

Understanding Wheel Thrown Ceramic Techniques

Wheel thrown ceramic techniques emphasize skilled hand control and precision shaping on a rotating pottery wheel, allowing artisans to create symmetrical, rounded forms with consistent wall thickness. This method enables dynamic manipulation of clay through centripetal force, giving rise to unique textures and nuanced details that are difficult to achieve with molded ceramics. Mastery of wheel throwing involves balancing speed, pressure, and timing, fostering a deep connection between potter and material for producing functional and artistic vessels.

What is Molded Ceramic Production?

Molded ceramic production involves shaping clay using pre-formed molds to ensure consistent and uniform designs, commonly used for mass-produced pottery and tiles. The process allows for high precision and repeatability, making it ideal for intricate patterns and complex shapes that are challenging to achieve with wheel thrown methods. Molded ceramics often exhibit smooth surfaces and detailed textures, enhancing both aesthetic appeal and functional qualities.

Key Differences Between Wheel Thrown and Molded Ceramics

Wheel-thrown ceramics are shaped by manually spinning clay on a potter's wheel, allowing for symmetrical and precise forms with unique tactile textures. Molded ceramics are created by pressing clay into pre-made molds, resulting in uniform shapes and consistent replication ideal for mass production. The key differences lie in the individuality and variability of wheel-thrown pieces versus the repeatability and efficiency of molded ceramics.

Material Consistency in Wheel Thrown vs Molded Ceramics

Wheel thrown ceramics exhibit greater material consistency due to the continuous shaping process, allowing for uniform thickness and density throughout the piece. Molded ceramics can experience variations in material distribution as clay is pressed into molds, potentially causing inconsistencies in wall thickness and strength. Maintaining precise control over clay moisture content and compression techniques in wheel throwing enhances the overall durability of the final product compared to molded ceramics.

Artistic Flexibility: Wheel Thrown vs Molded Approaches

Wheel-thrown ceramics offer unparalleled artistic flexibility, allowing potters to shape vessels dynamically with their hands, adjusting form and texture in real-time during the spinning process. Molded ceramics provide consistency and precision but limit creative variations to the original mold design, restricting spontaneous artistic expression. The tactile control in wheel throwing fosters unique, individualized pieces, while molding suits mass production with uniformity.

Surface Texture and Finishing Comparison

Wheel thrown ceramics exhibit concentric ridges and subtle variations in thickness, resulting in a tactile, organic surface texture that reflects the potter's hand. Molded ceramics feature uniform, smooth surfaces with consistent thickness, enabling precise and repeatable finishes that often lack the handcrafted nuances found in wheel thrown pieces. The finishing on wheel thrown items typically involves trimming and refining to enhance natural textures, whereas molded pieces may undergo additional surface treatments like glazing or polishing for a sleek, factory-produced appearance.

Durability and Structural Integrity: Which Is Better?

Wheel-thrown ceramics typically exhibit superior structural integrity due to the continuous and uniform clay alignment achieved during the throwing process, enhancing durability and resistance to cracking. Molded ceramics may contain weak points at mold seams or show uneven thickness, potentially reducing long-term strength and durability. Overall, wheel-thrown pieces tend to provide greater durability for functional uses demanding consistent mechanical performance.

Production Speed and Scalability

Wheel-thrown ceramics offer unique artistry but require significant time for shaping each piece, limiting production speed and scalability. Molded ceramics enable rapid, uniform reproduction by using pre-designed molds, significantly increasing output and consistency for large-scale manufacturing. Molded processes optimize efficiency and scalability, making them ideal for mass production compared to the slower, skill-intensive wheel throwing.

Sustainability and Material Waste Considerations

Wheel-thrown ceramics typically generate less material waste compared to molded processes due to precise clay usage and minimal trimming scraps. Molded ceramics often involve excess slip or clay overflow, leading to higher waste and energy consumption during mold production and maintenance. Sustainable ceramic practices favor wheel throwing to reduce raw material consumption and lower the environmental footprint associated with clay extraction and processing.

Choosing the Right Method for Your Ceramic Needs

Wheel thrown ceramics offer unique, handcrafted qualities with varied textures and organic shapes, ideal for artistic expression and custom designs. Molded ceramics provide consistency, efficiency, and precise replication, making them suitable for mass production and uniform product lines. Selecting the right method depends on your desired finish, production volume, and the importance of individual craftsmanship versus scalability.

Wheel Thrown vs Molded Infographic

materialdif.com

materialdif.com