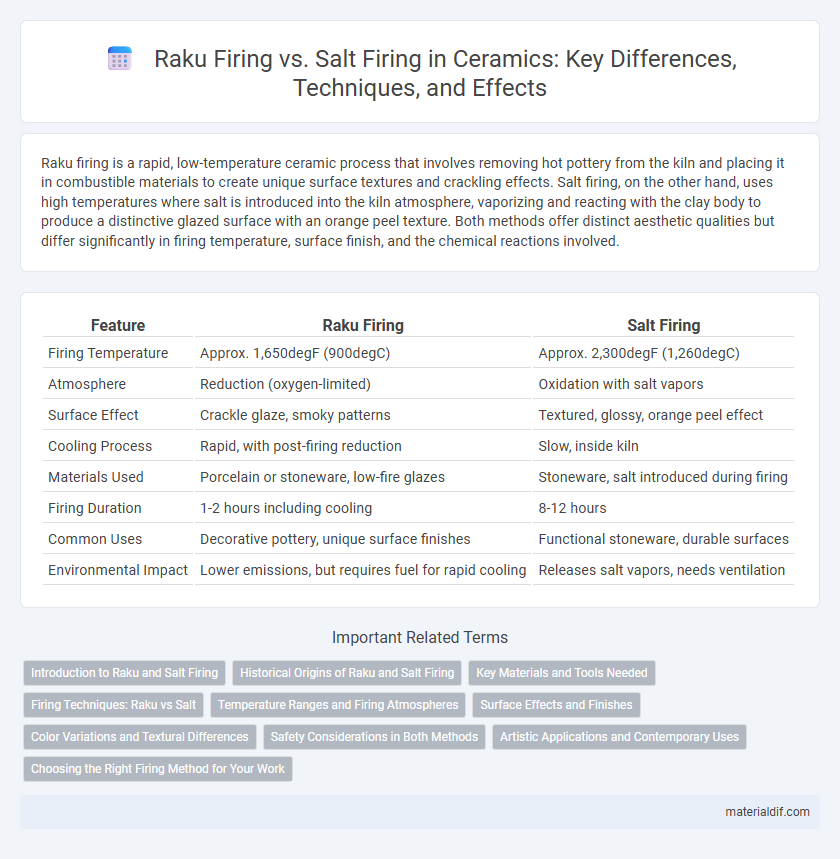

Raku firing is a rapid, low-temperature ceramic process that involves removing hot pottery from the kiln and placing it in combustible materials to create unique surface textures and crackling effects. Salt firing, on the other hand, uses high temperatures where salt is introduced into the kiln atmosphere, vaporizing and reacting with the clay body to produce a distinctive glazed surface with an orange peel texture. Both methods offer distinct aesthetic qualities but differ significantly in firing temperature, surface finish, and the chemical reactions involved.

Table of Comparison

| Feature | Raku Firing | Salt Firing |

|---|---|---|

| Firing Temperature | Approx. 1,650degF (900degC) | Approx. 2,300degF (1,260degC) |

| Atmosphere | Reduction (oxygen-limited) | Oxidation with salt vapors |

| Surface Effect | Crackle glaze, smoky patterns | Textured, glossy, orange peel effect |

| Cooling Process | Rapid, with post-firing reduction | Slow, inside kiln |

| Materials Used | Porcelain or stoneware, low-fire glazes | Stoneware, salt introduced during firing |

| Firing Duration | 1-2 hours including cooling | 8-12 hours |

| Common Uses | Decorative pottery, unique surface finishes | Functional stoneware, durable surfaces |

| Environmental Impact | Lower emissions, but requires fuel for rapid cooling | Releases salt vapors, needs ventilation |

Introduction to Raku and Salt Firing

Raku firing involves rapid heating and cooling of ceramics, producing unique crackle patterns and metallic finishes due to its reduction atmosphere. Salt firing introduces salt into a hot kiln, creating a textured, glossy surface as the salt reacts with the silica in the clay body. Both methods offer distinct aesthetic qualities, with Raku emphasizing spontaneity and Salt Firing highlighting natural surface effects.

Historical Origins of Raku and Salt Firing

Raku firing originated in 16th-century Japan, where it was developed by tea master Sen no Rikyu as a rapid firing technique for handcrafted tea bowls, emphasizing simplicity and natural textures. Salt firing dates back to 15th-century China and later spread to Europe, utilizing salt introduced into kiln atmospheres to create distinctive glazed surfaces through chemical reactions. Both methods reflect rich cultural heritages, with Raku rooted in Japanese tea ceremonies and Salt firing linked to traditional utilitarian pottery across Asia and Europe.

Key Materials and Tools Needed

Raku firing requires porous ceramic ware, a kiln with rapid heating capability, and tools such as tongs, gloves, and a reduction container filled with combustible materials like sawdust or newspaper for post-firing reduction. Salt firing involves a high-temperature kiln capable of reaching around 2,300degF (1,260degC), with salt (typically sodium chloride) introduced during the firing process to create a distinctive glaze; key tools include a kiln with a tight seal and protective gear to handle the corrosive salt fumes. Both techniques demand specific materials and safety equipment tailored to their unique thermal and atmospheric conditions.

Firing Techniques: Raku vs Salt

Raku firing involves rapidly heating ceramics and then cooling them through a post-firing reduction process, producing unique metallic and crackled surfaces. Salt firing introduces salt into a hot kiln, where it reacts with silica in the clay to create a distinct glaze texture and an orange-peel surface effect. Both techniques influence the final appearance and texture by altering the atmosphere and chemical reactions during firing.

Temperature Ranges and Firing Atmospheres

Raku firing typically occurs at lower temperatures between 1,650degF to 1,830degF (900degC to 1,000degC) and involves rapid cooling in an open-air reduction atmosphere that creates unique surface textures and crackles. Salt firing reaches higher temperatures around 2,300degF to 2,400degF (1,260degC to 1,320degC), where salt vapors react with silica in the clay to form a distinctive glaze on the ceramic surface in an oxidizing or slightly reducing atmosphere. Both firing methods produce contrasting effects due to their distinct temperature ranges and atmospheric conditions, impacting the final aesthetic and texture of the ceramic pieces.

Surface Effects and Finishes

Raku firing produces unique, crackled surfaces with metallic sheens and unpredictable color variations due to rapid cooling and reduction in a post-firing chamber. Salt firing creates a distinctive orange-peel texture and glossy, slightly glazed finish as salt vapor reacts with the silica in the clay body during high-temperature firing. Both methods yield organic, tactile surfaces but differ significantly in texture uniformity and color palette.

Color Variations and Textural Differences

Raku firing produces vibrant, unpredictable color variations with metallic sheens due to rapid cooling and reduction atmospheres, creating crackled, rough textures that emphasize surface irregularities. Salt firing introduces warm, earthy tones with a distinctive orange peel texture caused by salt vapor reacting with the clay body at high temperatures. These firing methods uniquely influence glaze appearance and surface feel, with Raku favoring dramatic contrasts and Salt firing offering subtle, textured finishes.

Safety Considerations in Both Methods

Raku firing involves rapid heating and cooling, which poses risks such as thermal shock and toxic fumes from combustible materials, necessitating proper ventilation and protective gear. Salt firing releases sodium vapor that reacts with silica in the clay, producing potentially hazardous smoke and requiring controlled kiln atmospheres and respiratory protection. Both firing methods demand strict safety protocols including fire-resistant clothing, eye protection, and well-ventilated firing areas to minimize exposure to heat and harmful emissions.

Artistic Applications and Contemporary Uses

Raku firing offers artists rapid cooling and unpredictable glaze effects, making it ideal for creating unique, one-of-a-kind ceramic pieces often used in contemporary sculptural works. Salt firing introduces a textured, glossy surface through vaporized salt interacting with the clay body, favored in functional ceramics like mugs and vases for its durability and rustic aesthetic. Both techniques remain popular in modern studios for their distinct visual qualities and ability to enhance artistic expression in handmade ceramics.

Choosing the Right Firing Method for Your Work

Raku firing offers rapid results and dramatic surface textures, ideal for artists seeking spontaneity and unique crackle effects, while salt firing produces durable, textured surfaces with a distinctive orange peel effect suited for functional pottery. Consider the thermal shock tolerance of your clay body, as raku requires materials that withstand sudden cooling, whereas salt firing involves prolonged high-temperature exposure that vitrifies the clay. Selecting the right method depends on the desired aesthetic, functional properties, and clay composition of your ceramic work.

Raku Firing vs Salt Firing Infographic

materialdif.com

materialdif.com