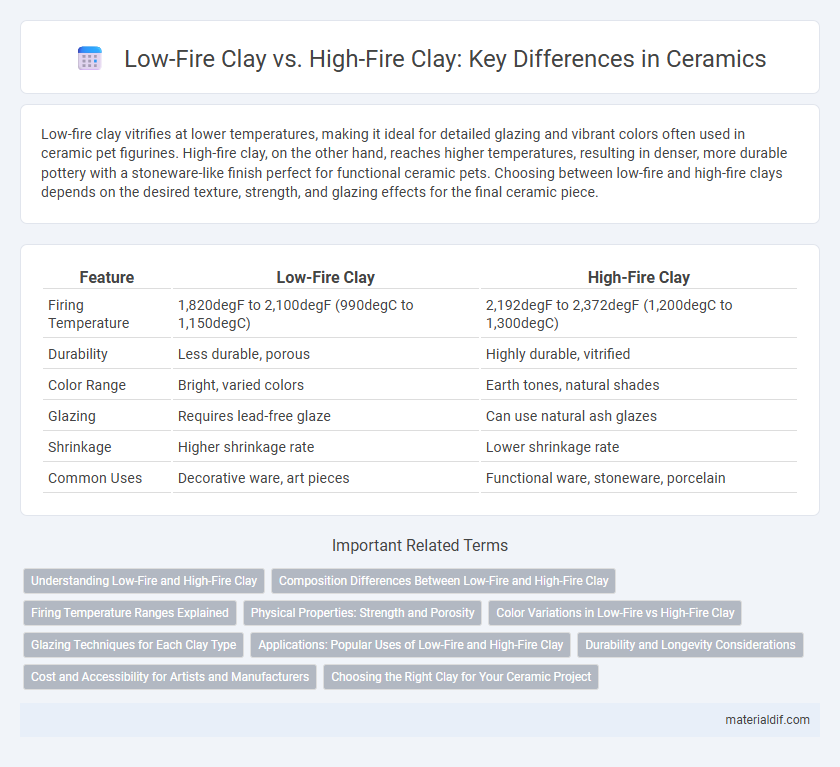

Low-fire clay vitrifies at lower temperatures, making it ideal for detailed glazing and vibrant colors often used in ceramic pet figurines. High-fire clay, on the other hand, reaches higher temperatures, resulting in denser, more durable pottery with a stoneware-like finish perfect for functional ceramic pets. Choosing between low-fire and high-fire clays depends on the desired texture, strength, and glazing effects for the final ceramic piece.

Table of Comparison

| Feature | Low-Fire Clay | High-Fire Clay |

|---|---|---|

| Firing Temperature | 1,820degF to 2,100degF (990degC to 1,150degC) | 2,192degF to 2,372degF (1,200degC to 1,300degC) |

| Durability | Less durable, porous | Highly durable, vitrified |

| Color Range | Bright, varied colors | Earth tones, natural shades |

| Glazing | Requires lead-free glaze | Can use natural ash glazes |

| Shrinkage | Higher shrinkage rate | Lower shrinkage rate |

| Common Uses | Decorative ware, art pieces | Functional ware, stoneware, porcelain |

Understanding Low-Fire and High-Fire Clay

Low-fire clay matures at temperatures between 1,830degF and 2,100degF (1,000degC to 1,150degC), resulting in porous, soft ceramics ideal for decorative pottery and beginner projects. High-fire clay vitrifies at temperatures ranging from 2,200degF to 2,400degF (1,200degC to 1,300degC), producing dense, durable stoneware and porcelain suited for functional ceramics and advanced techniques. Understanding the firing range and resulting material properties is crucial for selecting the appropriate clay body for specific artistic or utilitarian purposes.

Composition Differences Between Low-Fire and High-Fire Clay

Low-fire clay typically contains higher amounts of fluxes such as calcium and potassium, which allow it to mature at temperatures between cone 06 and cone 04 (1828degF to 1940degF). In contrast, high-fire clay is rich in alumina and silica, providing greater vitrification and strength when fired between cone 8 and cone 10 (2305degF to 2381degF). These compositional differences impact the durability, porosity, and color range of ceramic pieces produced from each type of clay.

Firing Temperature Ranges Explained

Low-fire clay typically matures at temperatures between 1,820degF and 2,100degF (990degC to 1,150degC), resulting in porous, vibrant glazes ideal for decorative ceramics. High-fire clay, on the other hand, requires firing temperatures from 2,192degF to 2,372degF (1,200degC to 1,300degC), producing vitrified, durable pottery suited for functional and stoneware applications. Understanding these firing temperature ranges is essential for selecting the appropriate clay body to match the desired strength, texture, and finish of ceramic projects.

Physical Properties: Strength and Porosity

Low-fire clay typically exhibits higher porosity and lower strength after firing, making it more absorbent and less durable for functional pottery or structural use. High-fire clay vitrifies more fully, resulting in greater strength and reduced porosity, which enhances water resistance and durability. These physical properties make high-fire clay ideal for stoneware and porcelain, whereas low-fire clay suits decorative or bisque-fired ceramics.

Color Variations in Low-Fire vs High-Fire Clay

Low-fire clay typically exhibits brighter and more vibrant color variations due to lower firing temperatures preserving iron and other mineral oxides, resulting in warm reds, oranges, and yellows. High-fire clay undergoes intense heat, often exceeding 2300degF, causing colors to mature into muted, earthy tones like browns, grays, and blues as the clay body vitrifies. The firing range significantly influences the final aesthetic, with low-fire clays favoring decorative pieces and high-fire clays suited for functional, durable ceramics.

Glazing Techniques for Each Clay Type

Low-fire clay requires glazing techniques that accommodate lower firing temperatures, often below 1,100degC (2,012degF), allowing for vibrant, glossy finishes with a wide range of colors but necessitating careful control to prevent glaze defects like crawling or pinholing. High-fire clay, typically fired above 1,200degC (2,192degF), demands durable glazes that mature well at higher temperatures, producing more subdued, earth-toned finishes with enhanced vitrification and reduced porosity. Understanding the thermal expansion and melting points of glazes relative to the clay body is critical in preventing crazing or shivering for both low- and high-fire ceramics.

Applications: Popular Uses of Low-Fire and High-Fire Clay

Low-fire clay is preferred for creating colorful, detailed pottery and decorative ceramics due to its ability to withstand lower firing temperatures, making it ideal for miniature sculptures, earthenware, and functional items like mugs and vases. High-fire clay excels in producing durable stoneware and porcelain, commonly used for tableware, tiles, and architectural ceramics that require strength and resistance to heat and chemicals. Both types serve distinct applications, with low-fire clay favored for artistic expression and high-fire clay chosen for functional and structural ceramic products.

Durability and Longevity Considerations

Low-fire clay typically matures at temperatures between 1,820degF and 2,100degF, creating ceramic pieces that are more porous and less durable compared to high-fire clay, which matures between 2,300degF and 2,400degF and results in denser, vitrified pottery. High-fire ceramics exhibit superior resistance to chipping, cracking, and thermal shock, contributing to significantly enhanced longevity in both functional and decorative applications. When selecting clay for projects requiring durable, long-lasting results, high-fire clay offers distinct advantages in structural integrity and wear resistance over low-fire alternatives.

Cost and Accessibility for Artists and Manufacturers

Low-fire clay typically costs less and is more accessible for artists and manufacturers due to its lower firing temperature, which reduces energy consumption and kiln wear. High-fire clay demands higher temperatures, increasing kiln operation costs and limiting accessibility for smaller studios or budget-conscious creators. Budget constraints and equipment availability often guide the choice between low-fire and high-fire clays in ceramics production.

Choosing the Right Clay for Your Ceramic Project

Low-fire clay matures at temperatures between 1,650degF and 2,100degF, offering vibrant color possibilities and faster firing times, making it ideal for decorative ceramics and detailed work. High-fire clay, maturing at temperatures above 2,300degF, produces denser, more durable pottery suited for functional items like dinnerware and stoneware. Selecting the right clay depends on the project's intended use, desired finish, and firing equipment capabilities.

Low-Fire Clay vs High-Fire Clay Infographic

materialdif.com

materialdif.com