Ceramic slip casting involves pouring liquid clay slip into a plaster mold, allowing it to form a uniform wall by absorbing water, ideal for complex shapes and fine details with minimal surface imperfections. Press molding uses compressing clay into a rigid mold, providing faster production and consistent thickness but often limiting intricate designs and resulting in heavier parts. Both techniques influence the final texture, strength, and aesthetic properties of ceramic products, with slip casting excelling in precision and press molding in efficiency.

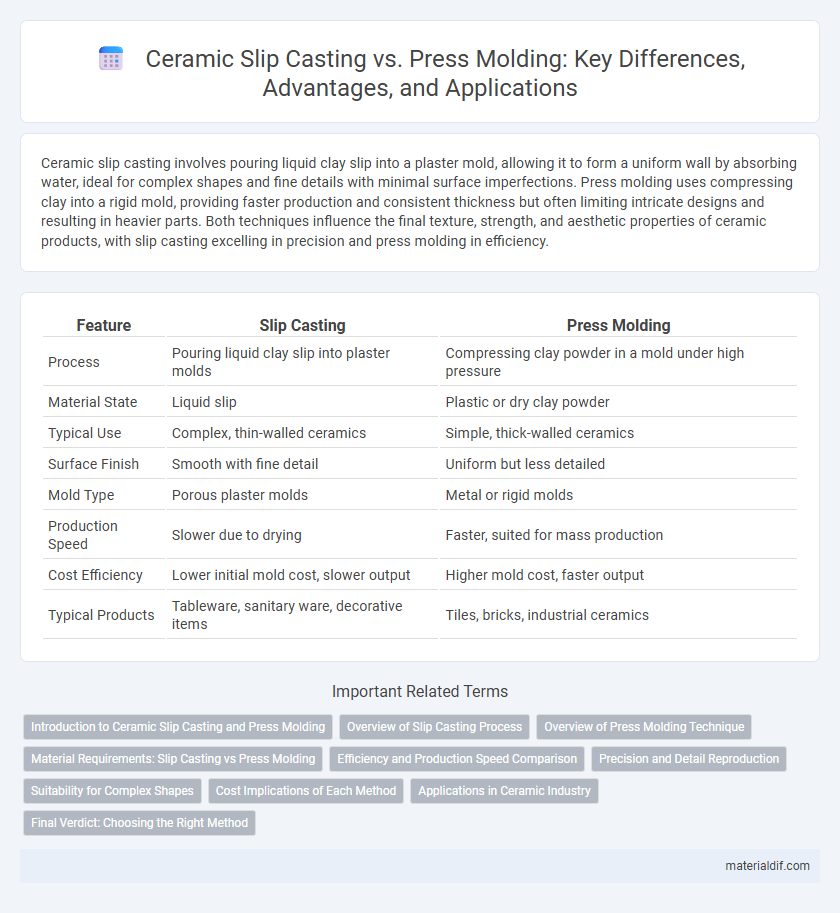

Table of Comparison

| Feature | Slip Casting | Press Molding |

|---|---|---|

| Process | Pouring liquid clay slip into plaster molds | Compressing clay powder in a mold under high pressure |

| Material State | Liquid slip | Plastic or dry clay powder |

| Typical Use | Complex, thin-walled ceramics | Simple, thick-walled ceramics |

| Surface Finish | Smooth with fine detail | Uniform but less detailed |

| Mold Type | Porous plaster molds | Metal or rigid molds |

| Production Speed | Slower due to drying | Faster, suited for mass production |

| Cost Efficiency | Lower initial mold cost, slower output | Higher mold cost, faster output |

| Typical Products | Tableware, sanitary ware, decorative items | Tiles, bricks, industrial ceramics |

Introduction to Ceramic Slip Casting and Press Molding

Ceramic slip casting involves pouring liquid clay slip into a porous mold, allowing water to be absorbed and a solid ceramic layer to form along the mold walls, resulting in intricate and hollow shapes. Press molding uses dry or semi-dry clay pressed into rigid molds, producing dense and uniform ceramic parts with faster cycle times. Slip casting excels in complex, thin-walled designs, while press molding is preferred for high-volume production of solid components.

Overview of Slip Casting Process

Slip casting involves pouring a liquid clay slip into a porous mold, allowing water to be absorbed and a solid layer to form on the mold's interior surfaces. This process is ideal for creating complex shapes with thin walls and fine details, commonly used in producing ceramic tableware and sanitary ware. Compared to press molding, slip casting offers greater versatility in shape design but typically requires longer drying times and careful control of slip viscosity.

Overview of Press Molding Technique

Press molding in ceramics involves shaping clay or slip by pressing it into a rigid mold under controlled pressure, enabling precise and consistent production of complex shapes. This technique offers faster cycle times and reduced material waste compared to slip casting, which relies on liquid slip filling porous molds gradually. Press molding is ideal for high-volume manufacturing of thicker-walled ceramic parts, ensuring uniform density and mechanical strength.

Material Requirements: Slip Casting vs Press Molding

Slip casting requires a liquid clay body with fine particle size and controlled viscosity to flow easily into molds, ensuring uniform thickness and detail replication. Press molding depends on a more plastic and cohesive clay body that can withstand pressure without cracking while maintaining shape integrity. The material formulation for slip casting prioritizes fluidity and deflocculation agents, whereas press molding emphasizes plasticity and particle cohesion for optimal mold filling and surface finish.

Efficiency and Production Speed Comparison

Ceramic slip casting offers superior efficiency for complex shapes by allowing continuous production with minimal mold wear, whereas press molding excels in speed for simple, high-volume parts due to rapid cycle times and less drying time. Slip casting requires longer setting periods but provides better precision and material utilization, making it ideal for intricate designs. Press molding reduces labor and energy costs with faster throughput, suitable for large-scale manufacturing of uniform ceramic components.

Precision and Detail Reproduction

Ceramic slip casting offers superior precision and intricate detail reproduction by allowing liquid clay to fill complex molds evenly, capturing fine textures and delicate features with high accuracy. Press molding, while efficient for simpler shapes, tends to produce less detailed surfaces due to the compaction process and potential for material deformation. The ability of slip casting to create thin-walled, hollow components enhances its advantage in achieving exact and detailed ceramic pieces.

Suitability for Complex Shapes

Ceramic slip casting excels in producing complex shapes with intricate details due to the fluid nature of the slip, which fills molds uniformly and captures fine features. Press molding, however, is better suited for simpler, flatter designs as the clay is compacted under pressure, limiting its ability to form highly detailed or undercut geometries. For intricate ceramic components, slip casting offers superior precision and versatility compared to press molding.

Cost Implications of Each Method

Ceramic slip casting involves pouring liquid clay slip into a porous mold, resulting in high labor costs due to longer drying times and multiple processing steps, but lower mold production expenses compared to press molding. Press molding utilizes pre-formed clay slabs pressed into molds, leading to higher initial costs for durable mold fabrication but faster cycle times and reduced labor expenses. Overall, slip casting is more cost-effective for small production runs, while press molding offers better economies of scale for large-volume manufacturing.

Applications in Ceramic Industry

Ceramic slip casting is widely used in the production of complex, hollow, or intricately shaped ceramic items such as sanitary ware, tiles, and decorative objects due to its ability to create uniform thickness and fine detail. Press molding excels in manufacturing high-density, mechanical-strength ceramics like electrical insulators and cutting tools by applying pressure to ceramic powder within a mold, resulting in faster production cycles and higher structural integrity. The ceramic industry leverages slip casting for artistic and precision applications while relying on press molding for functional components requiring durability and dimensional accuracy.

Final Verdict: Choosing the Right Method

Slip casting offers superior detail and uniformity, ideal for complex ceramic shapes and fine surface finishes, while press molding excels in high-volume production with consistent thickness and strength. The choice depends on production scale and design complexity: slip casting suits artisanal and intricate designs, whereas press molding is optimal for mass manufacturing robust, simple forms. Balancing quality, efficiency, and application needs ensures selecting the most effective ceramic forming method.

Ceramic slip casting vs Press molding Infographic

materialdif.com

materialdif.com