Bisque firing transforms raw clay into durable ceramic by heating it at a lower temperature, making the pottery more porous and easier to glaze. Glost firing follows bisque firing, applying a glaze coating and vitrifying the pottery at a higher temperature to create a smooth, glass-like surface. Understanding the distinction between bisque firing and glost firing is essential for achieving desired durability and finish in ceramic work.

Table of Comparison

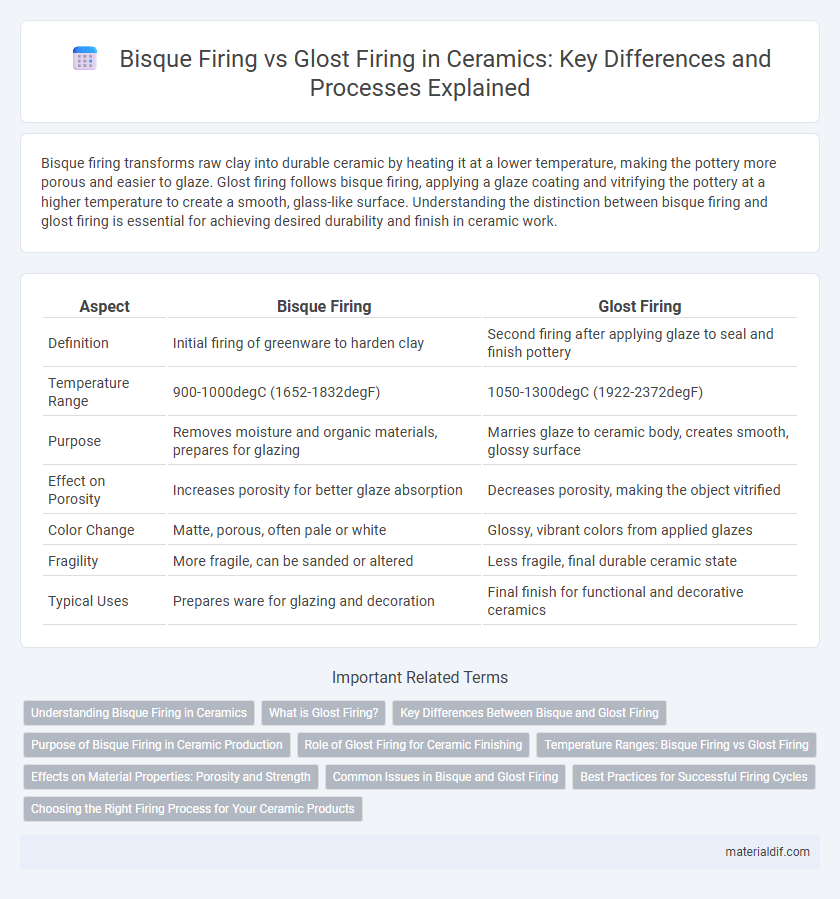

| Aspect | Bisque Firing | Glost Firing |

|---|---|---|

| Definition | Initial firing of greenware to harden clay | Second firing after applying glaze to seal and finish pottery |

| Temperature Range | 900-1000degC (1652-1832degF) | 1050-1300degC (1922-2372degF) |

| Purpose | Removes moisture and organic materials, prepares for glazing | Marries glaze to ceramic body, creates smooth, glossy surface |

| Effect on Porosity | Increases porosity for better glaze absorption | Decreases porosity, making the object vitrified |

| Color Change | Matte, porous, often pale or white | Glossy, vibrant colors from applied glazes |

| Fragility | More fragile, can be sanded or altered | Less fragile, final durable ceramic state |

| Typical Uses | Prepares ware for glazing and decoration | Final finish for functional and decorative ceramics |

Understanding Bisque Firing in Ceramics

Bisque firing is the first kiln firing of ceramic ware, transforming clay into a porous, hardened state that is easier to handle and glaze. This firing typically occurs at temperatures between bisque firing usually occurs between 1730degF and 1940degF (945degC to 1060degC), driving off chemically bound water without vitrifying the clay. Understanding bisque firing is crucial for controlling porosity and durability before glost firing, which solidifies the glaze and vitrifies the ceramic piece.

What is Glost Firing?

Glost firing is the second and final kiln firing process that vitrifies the ceramic glaze applied to bisque-fired pottery. It involves heating the glazed ceramics to a high temperature, typically between 1,200degC and 1,300degC, to melt and fuse the glaze, creating a smooth, glass-like surface. This firing enhances the durability, appearance, and functionality of ceramic pieces by sealing the porous bisque ware beneath.

Key Differences Between Bisque and Glost Firing

Bisque firing transforms clay into a porous, durable state by heating it to approximately bisque temperature ranges from bisque firing temperatures of bisque firing in electric or gas kilns typically reaches from bisque firing temperatures of 900 to 1000degC (1652 to 1832degF), making the ceramic piece more resilient yet still absorbent for glaze application. Glost firing, on the other hand, is conducted at higher temperatures, around 1200degC to 1300degC (2192degF to 2372degF), which vitrifies the glaze, forming a glossy, waterproof surface and completing the ceramic piece's maturation. The key differences lie in firing temperature, purpose--bisque firing solidifies and prepares for glazing, while glost firing matures and seals the glaze--and physical properties, with bisque ware remaining porous and glost ware becoming vitrified and non-porous.

Purpose of Bisque Firing in Ceramic Production

Bisque firing in ceramic production serves primarily to transform fragile, unfired clay into a porous but durable state, allowing it to withstand handling and glazing processes without damage. This initial firing typically occurs at temperatures between 1730degF and 1940degF (945degC to 1060degC), removing chemically bound water and organic materials to stabilize the clay body. By creating a porous surface, bisque ware efficiently absorbs glazes during subsequent glost firing, which vitrifies the piece at higher temperatures to develop its final, glass-like finish.

Role of Glost Firing for Ceramic Finishing

Glost firing plays a crucial role in ceramic finishing by vitrifying the glaze, which creates a smooth, glass-like surface that enhances both the aesthetic appeal and durability of the ceramic piece. This process typically occurs after bisque firing, where the ceramic body is hardened but porous, allowing the glaze to properly adhere and mature during glost firing. The controlled high-temperature environment of glost firing ensures the glaze melts and fuses uniformly, resulting in a protective, often glossy finish that is essential for functional and decorative ceramics.

Temperature Ranges: Bisque Firing vs Glost Firing

Bisque firing typically occurs at temperatures between 1,650degF and 1,940degF (900degC to 1,060degC), which hardens the clay without vitrifying it, leaving the ceramic porous for glazing. Glost firing, also known as glaze firing, takes place at higher temperatures ranging from 1,830degF to 2,380degF (1,000degC to 1,300degC), melting the glaze to form a smooth, glassy surface. Precise control of these temperature ranges is crucial to achieve the desired ceramic properties and avoid defects like warping or glaze crawling.

Effects on Material Properties: Porosity and Strength

Bisque firing transforms clay into a porous, rigid ceramic body by driving off chemically bound water and organic materials, enhancing its mechanical strength while maintaining enough porosity for glaze absorption. Glost firing vitrifies the ceramic surface, significantly reducing porosity and increasing density, which results in enhanced strength and improved durability. The combined firing process balances porosity and strength, optimizing the ceramic's functional and aesthetic properties for final use.

Common Issues in Bisque and Glost Firing

Bisque firing often faces common issues such as cracking, warping, and incomplete vitrification due to uneven heating or rapid temperature changes. Glost firing problems typically include glaze defects like crawling, pinholing, and blistering, which result from improper glaze application or firing schedules. Both firings require precise temperature control and careful monitoring to minimize defects and ensure ceramic durability.

Best Practices for Successful Firing Cycles

Bisque firing involves heating ceramic ware to a temperature between 1730degF and 1940degF to remove moisture and organic compounds, creating a porous but strong structure ideal for glazing. Glost firing follows bisque firing and typically occurs at higher temperatures, around 2167degF to 2345degF, vitrifying the glaze and forming a glassy surface that enhances durability and aesthetic appeal. Precise temperature control and gradual heating rates during both firing cycles are critical to prevent thermal shock, cracking, and glaze defects, ensuring successful ceramic outcomes.

Choosing the Right Firing Process for Your Ceramic Products

Selecting the appropriate firing process for your ceramic products depends on the desired finish and durability. Bisque firing transforms clay into a porous, hardened state ideal for glazing, while glost firing applies the glaze and solidifies the surface for waterproofing and strength. Understanding the thermal properties and end-use requirements ensures optimal results in ceramic production.

Bisque Firing vs Glost Firing Infographic

materialdif.com

materialdif.com