Oxide coloring uses natural metal oxides to create rich, deep hues in ceramics, offering excellent durability and a more traditional, earthy appearance. Stain coloring, on the other hand, employs pre-mixed pigments that provide a wider color range and greater consistency, making it ideal for decorative details and precise color matching. Both methods enhance ceramic aesthetics but differ in application techniques, color longevity, and visual effects.

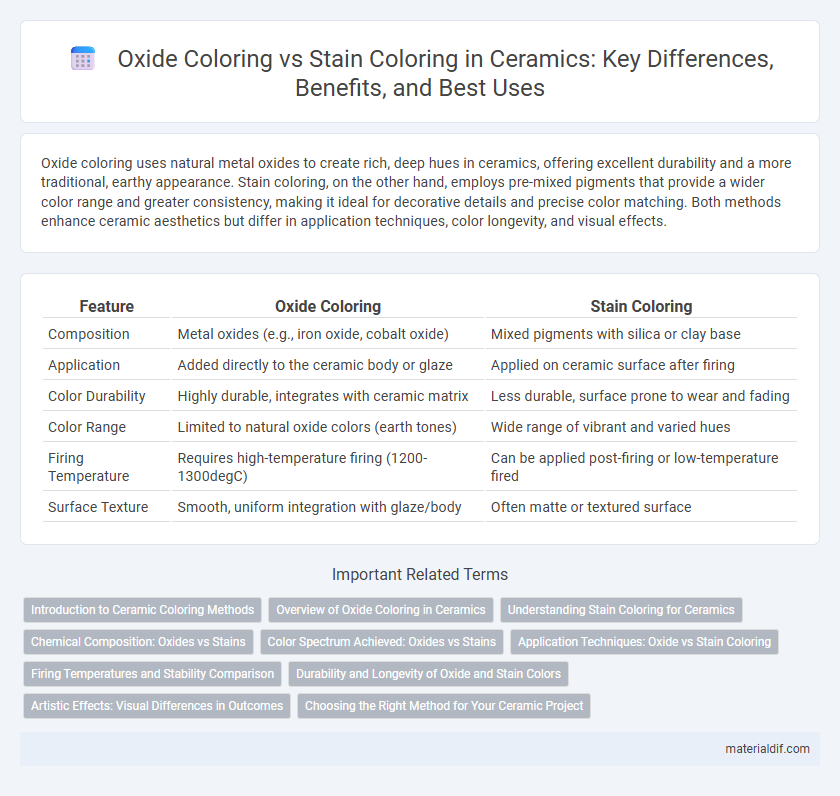

Table of Comparison

| Feature | Oxide Coloring | Stain Coloring |

|---|---|---|

| Composition | Metal oxides (e.g., iron oxide, cobalt oxide) | Mixed pigments with silica or clay base |

| Application | Added directly to the ceramic body or glaze | Applied on ceramic surface after firing |

| Color Durability | Highly durable, integrates with ceramic matrix | Less durable, surface prone to wear and fading |

| Color Range | Limited to natural oxide colors (earth tones) | Wide range of vibrant and varied hues |

| Firing Temperature | Requires high-temperature firing (1200-1300degC) | Can be applied post-firing or low-temperature fired |

| Surface Texture | Smooth, uniform integration with glaze/body | Often matte or textured surface |

Introduction to Ceramic Coloring Methods

Oxide coloring in ceramics involves the use of metal oxides such as iron oxide, cobalt oxide, or copper oxide to directly alter the clay or glaze color during firing, offering rich and durable hues. Stain coloring relies on pre-made ceramic stains containing concentrated pigments that provide consistent, predictable colors and are often applied to surface decoration. Both methods enhance ceramic aesthetics with oxide coloring favored for its natural integration and stain coloring preferred for precise, vibrant finishes.

Overview of Oxide Coloring in Ceramics

Oxide coloring in ceramics involves the use of metal oxides such as iron oxide, cobalt oxide, and chromium oxide to create vibrant and durable colors during the firing process. These oxides chemically interact with clay and glaze materials at high temperatures, resulting in unique hues that are integral to the ceramic body rather than surface-applied stains. This method is favored for its lasting color stability and seamless integration within various ceramic firing atmospheres.

Understanding Stain Coloring for Ceramics

Stain coloring in ceramics involves using finely ground metal oxides or commercial stains mixed with a medium to create specific hues and effects on clay surfaces. Unlike oxide coloring, which relies on raw metal oxides that can vary in color and intensity, stains are manufactured for consistency and predictable results during firing. This precision makes stain coloring ideal for achieving detailed designs and uniform coloration in ceramic art and functional ware.

Chemical Composition: Oxides vs Stains

Oxide coloring in ceramics primarily uses metal oxides such as iron oxide, cobalt oxide, and chromium oxide, which chemically integrate into the clay body or glaze, creating durable and vibrant hues resistant to high temperatures. In contrast, stain coloring involves synthetic or natural pigments composed of complex chemical compounds that may include titanium, zirconium, or cerium oxides combined with other elements, offering a broader color range with consistent intensity and stability. The chemical composition of oxides allows for more subtle, earthy tones, while stains provide brighter, more precise colors due to their engineered formulations.

Color Spectrum Achieved: Oxides vs Stains

Oxide coloring in ceramics offers a narrow color spectrum dominated by earthy tones like reds, browns, and greens due to the metal oxides' chemical composition. Stain coloring provides a broader and more vibrant color range, including blues, purples, and bright hues, achieved by finely ground pigments that maintain stability at high firing temperatures. The choice between oxides and stains significantly affects the depth and variety of colors possible in ceramic glazes and surfaces.

Application Techniques: Oxide vs Stain Coloring

Oxide coloring in ceramics involves applying metal oxide powders directly onto the clay surface or mixing them into the clay body, producing natural, earthy tones through high-temperature firing. Stain coloring, however, utilizes finely ground ceramic pigments combined with various mediums to create more vivid, consistent, and customizable colors that adhere well during glazing or overglazing. Application techniques for oxides often include brushing, sponging, or spraying, while stains require precise suspension in liquids for controlled application, allowing for greater detail and color stability.

Firing Temperatures and Stability Comparison

Oxide coloring in ceramics involves metal oxides like iron or cobalt, which fuse with the clay body at higher firing temperatures, enhancing color stability and durability. Stain coloring uses pre-mixed ceramic stains that remain stable across a wider firing range, offering consistent color results even with variable kiln atmospheres. Firing temperature critically affects oxide colors by altering their chemical state, while stains maintain color integrity due to their engineered compounds designed for temperature resilience.

Durability and Longevity of Oxide and Stain Colors

Oxide coloring in ceramics offers superior durability due to its chemical composition, which bonds strongly with the clay body and withstands high firing temperatures without fading. Stain coloring, while versatile and vibrant, is more prone to wear and color degradation over time, especially when exposed to abrasive surfaces or UV light. The longevity of oxide colors makes them ideal for functional ceramics requiring long-lasting finishes and consistent color stability.

Artistic Effects: Visual Differences in Outcomes

Oxide coloring in ceramics produces rich, earthy tones with natural variations that enhance texture and depth, giving pieces a more organic, traditional appearance. Stain coloring offers a broader palette with consistent, vibrant hues that maintain sharp definition and smooth surface finishes, ideal for intricate designs and contemporary styles. Choosing between oxide and stain coloring depends on desired visual effects, as oxides emphasize subtle, muted shades while stains deliver bold, uniform colors.

Choosing the Right Method for Your Ceramic Project

Oxide coloring in ceramics offers deep, natural hues derived from metal oxides like iron, cobalt, and copper, providing durability and subtle tonal variations ideal for functional ware. Stain coloring uses pre-mixed ceramic stains that produce consistent, vibrant colors and intricate designs, perfect for detailed decoration and repeatability in production. Selecting the right method depends on the desired aesthetic, durability, and application technique, where oxides are preferred for organic, earthy effects and stains suit precise, bold color requirements.

Oxide Coloring vs Stain Coloring Infographic

materialdif.com

materialdif.com