Ball clay is highly plastic and fine-grained, making it ideal for improving the workability and strength of ceramic bodies, while kaolin clay is less plastic but purer, providing whiteness and refractory properties essential for porcelain production. Ball clay contains higher amounts of organic material and impurities, contributing to its plasticity but requiring careful processing, whereas kaolin is composed mainly of the mineral kaolinite, resulting in low plasticity but excellent firing performance. Choosing between ball clay and kaolin depends on the desired ceramic characteristics, such as strength, translucency, and firing temperature.

Table of Comparison

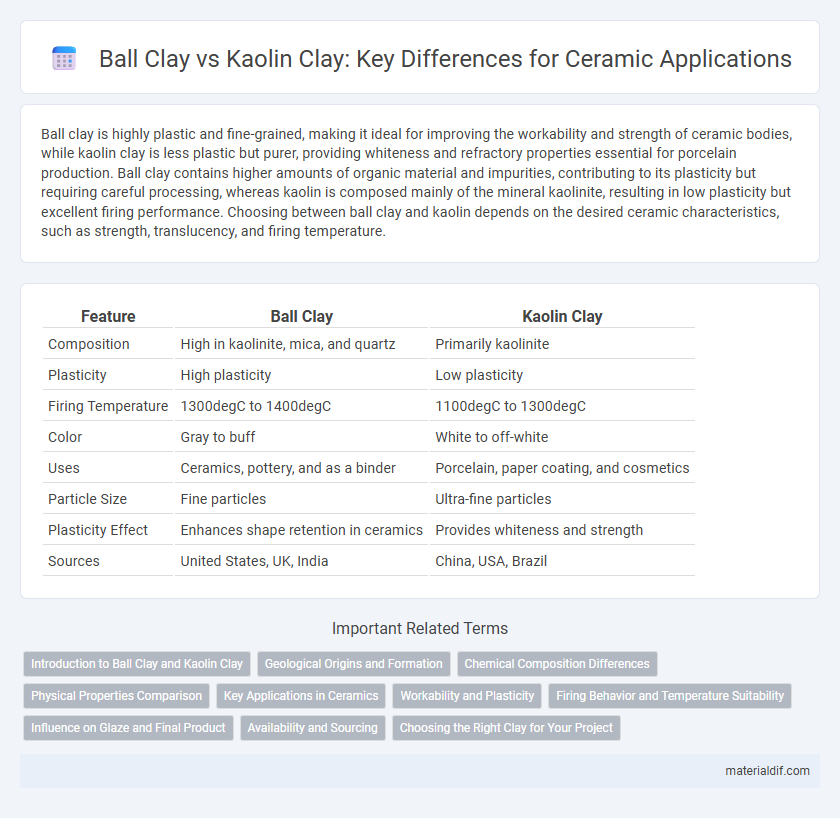

| Feature | Ball Clay | Kaolin Clay |

|---|---|---|

| Composition | High in kaolinite, mica, and quartz | Primarily kaolinite |

| Plasticity | High plasticity | Low plasticity |

| Firing Temperature | 1300degC to 1400degC | 1100degC to 1300degC |

| Color | Gray to buff | White to off-white |

| Uses | Ceramics, pottery, and as a binder | Porcelain, paper coating, and cosmetics |

| Particle Size | Fine particles | Ultra-fine particles |

| Plasticity Effect | Enhances shape retention in ceramics | Provides whiteness and strength |

| Sources | United States, UK, India | China, USA, Brazil |

Introduction to Ball Clay and Kaolin Clay

Ball clay and kaolin clay are essential raw materials in ceramic manufacturing, each offering unique properties for shaping and firing processes. Ball clay is highly plastic, composed mainly of kaolinite, mica, and quartz, providing excellent workability and green strength for ceramic bodies. Kaolin clay, also known as China clay, contains a high percentage of pure kaolinite, yielding whiteness and refractory qualities crucial for porcelain and high-fire ceramics.

Geological Origins and Formation

Ball clay originates from sedimentary deposits formed by the weathering and erosion of feldspathic rocks in ancient river basins, rich in organic matter and fine minerals that contribute to its plasticity. Kaolin clay, also known as china clay, develops through the chemical weathering of feldspar-rich igneous rocks such as granite, resulting in a pure, white clay composed mainly of the mineral kaolinite. The geological formation processes influence their mineral composition, particle size, and suitability for specific ceramic applications.

Chemical Composition Differences

Ball clay contains higher amounts of organic matter and impurities, with a chemical composition primarily of 60-70% kaolinite, 20-30% mica, and smaller amounts of quartz, resulting in increased plasticity and firing shrinkage. Kaolin clay is mainly composed of nearly pure kaolinite (Al2Si2O5(OH)4), featuring low impurity levels which provide whiteness, high refractoriness, and minimal plasticity. The distinct chemical composition differences between ball clay and kaolin clay significantly affect their applications in ceramics, with ball clay preferred for plasticity enhancement and kaolin valued for whiteness and strength in porcelain production.

Physical Properties Comparison

Ball clay exhibits higher plasticity and finer particle size than kaolin clay, making it ideal for shaping and molding in ceramics. Kaolin clay, known for its whiteness and lower plasticity, provides strength and durability but requires blending with more plastic clays like ball clay to improve workability. Moisture content in ball clay is generally higher, enhancing flexibility, while kaolin clay offers higher refractory properties and lower shrinkage after firing.

Key Applications in Ceramics

Ball clay is primarily used in ceramics for its plasticity and binding properties, making it ideal in the production of whiteware, sanitaryware, and porcelain bodies. Kaolin clay, known for its purity and whiteness, is essential in high-quality porcelain, porcelain enamel, and fine china, contributing to strength and translucency. Both clays optimize ceramic formulations but serve distinct roles based on their particle size, mineral composition, and firing characteristics.

Workability and Plasticity

Ball clay exhibits higher plasticity and superior workability compared to kaolin clay, making it ideal for forming complex shapes and detailed ceramics. Kaolin clay has lower plasticity but offers greater refractory properties and whiteness, often used to provide structure and strength in ceramic blends. Combining ball clay with kaolin enhances the overall plasticity and firing characteristics in ceramic production.

Firing Behavior and Temperature Suitability

Ball clay offers excellent plasticity and fires at lower temperatures around 1100-1200degC, producing a strong, vitrified body ideal for functional ceramics. Kaolin clay requires higher firing temperatures, generally between 1200-1400degC, resulting in a white, translucent, and refractory ceramic suitable for porcelain and fine china. The difference in firing behavior is crucial for selecting the right clay based on desired strength, whiteness, and thermal resistance in ceramic production.

Influence on Glaze and Final Product

Ball clay enhances glaze adhesion and plasticity, resulting in a smoother surface and increased durability in the final ceramic product. Kaolin clay contributes to a whiter, more translucent glaze with higher resistance to thermal shock, improving the overall aesthetic and strength. The combination of ball clay and kaolin optimizes both glaze texture and structural integrity, balancing workability and finished appearance.

Availability and Sourcing

Ball clay is abundantly sourced from sedimentary deposits primarily found in the southeastern United States, particularly Tennessee and Kentucky, ensuring a steady supply for ceramic production. Kaolin clay, also known as china clay, is extensively mined in regions like Georgia, USA, and in parts of China, providing high-purity material critical for fine porcelain and industrial ceramics. The availability of ball clay generally supports bulk ceramic body formulations, while kaolin's sourcing is more specialized due to its higher whiteness and firing properties.

Choosing the Right Clay for Your Project

Ball clay offers high plasticity and excellent workability, making it ideal for intricate ceramic shapes and fine details, while kaolin clay provides superior whiteness and higher firing temperatures suited for porcelain and high-fire ceramics. Selecting the right clay depends on project requirements: use ball clay for enhanced plasticity and strength in forming, or kaolin clay for purity, strength, and translucency in finished pieces. Balancing these properties ensures optimal performance and aesthetic results in ceramic creations.

Ball Clay vs Kaolin Clay Infographic

materialdif.com

materialdif.com