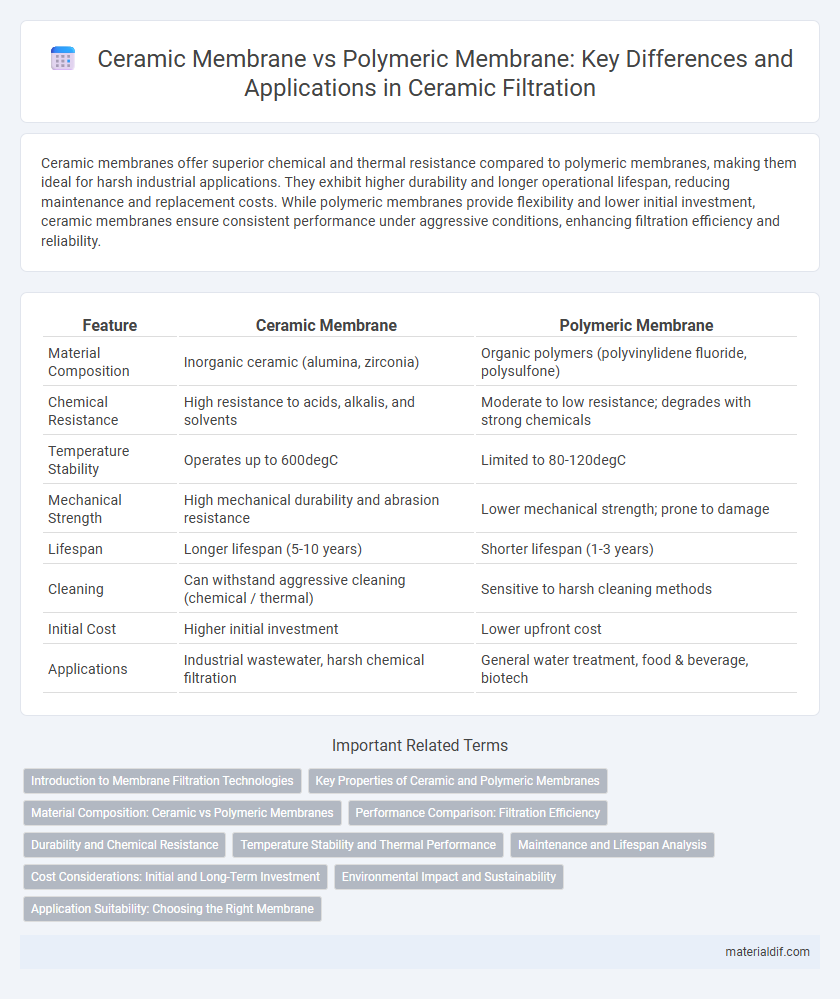

Ceramic membranes offer superior chemical and thermal resistance compared to polymeric membranes, making them ideal for harsh industrial applications. They exhibit higher durability and longer operational lifespan, reducing maintenance and replacement costs. While polymeric membranes provide flexibility and lower initial investment, ceramic membranes ensure consistent performance under aggressive conditions, enhancing filtration efficiency and reliability.

Table of Comparison

| Feature | Ceramic Membrane | Polymeric Membrane |

|---|---|---|

| Material Composition | Inorganic ceramic (alumina, zirconia) | Organic polymers (polyvinylidene fluoride, polysulfone) |

| Chemical Resistance | High resistance to acids, alkalis, and solvents | Moderate to low resistance; degrades with strong chemicals |

| Temperature Stability | Operates up to 600degC | Limited to 80-120degC |

| Mechanical Strength | High mechanical durability and abrasion resistance | Lower mechanical strength; prone to damage |

| Lifespan | Longer lifespan (5-10 years) | Shorter lifespan (1-3 years) |

| Cleaning | Can withstand aggressive cleaning (chemical / thermal) | Sensitive to harsh cleaning methods |

| Initial Cost | Higher initial investment | Lower upfront cost |

| Applications | Industrial wastewater, harsh chemical filtration | General water treatment, food & beverage, biotech |

Introduction to Membrane Filtration Technologies

Ceramic membranes offer superior chemical resistance, thermal stability, and mechanical strength compared to polymeric membranes, making them ideal for harsh industrial filtration applications. Polymeric membranes, derived from materials like polysulfone and polyethersulfone, provide cost-effective and flexible solutions suitable for water treatment and food processing with lower fouling tendencies. Membrane filtration technologies harness these materials to achieve microfiltration, ultrafiltration, and nanofiltration, optimizing separation efficiency based on specific process requirements.

Key Properties of Ceramic and Polymeric Membranes

Ceramic membranes exhibit superior chemical resistance, thermal stability, and mechanical strength compared to polymeric membranes, making them ideal for harsh industrial applications. Polymeric membranes offer flexibility, lower cost, and ease of fabrication but are more prone to fouling and chemical degradation. The high pore precision and durability of ceramic membranes enhance filtration efficiency and longevity in processes involving aggressive solvents or high temperatures.

Material Composition: Ceramic vs Polymeric Membranes

Ceramic membranes consist primarily of inorganic materials such as alumina, zirconia, or silicon carbide, offering superior chemical, thermal, and mechanical stability compared to polymeric membranes, which are made from organic polymers like polysulfone, polyethersulfone, or PVDF. This inherent robustness enables ceramic membranes to withstand aggressive cleaning agents and high temperatures, making them ideal for demanding industrial applications. Conversely, polymeric membranes provide greater flexibility, lower initial costs, and easier fabrication but often suffer from lower resistance to fouling and chemical degradation.

Performance Comparison: Filtration Efficiency

Ceramic membranes exhibit higher filtration efficiency compared to polymeric membranes due to their smaller and more uniform pore size distribution, enabling superior removal of fine particles and microorganisms. Their chemical and thermal stability allows ceramic membranes to maintain consistent performance under harsh operating conditions, unlike polymeric membranes which may degrade or foul more easily. This durability ensures prolonged filtration efficiency, reducing maintenance frequency and operational costs in industrial applications.

Durability and Chemical Resistance

Ceramic membranes exhibit superior durability and chemical resistance compared to polymeric membranes, making them ideal for harsh industrial applications involving extreme pH levels and aggressive solvents. Their robust inorganic structure allows for repeated cleaning cycles and high-temperature operation without degradation. In contrast, polymeric membranes are more susceptible to fouling, chemical attack, and thermal damage, limiting their lifespan and performance in demanding environments.

Temperature Stability and Thermal Performance

Ceramic membranes exhibit superior temperature stability compared to polymeric membranes, maintaining structural integrity at temperatures above 300degC, whereas polymeric membranes typically degrade or lose performance above 80-120degC. The thermal performance of ceramic membranes allows for operation in harsh industrial environments involving high-temperature gases or liquids, enabling efficient filtration without the need for cooling. This high thermal resistance also extends the membrane lifespan and reduces downtime for maintenance in processes such as wastewater treatment and chemical processing.

Maintenance and Lifespan Analysis

Ceramic membranes exhibit superior chemical and thermal resistance compared to polymeric membranes, resulting in significantly longer lifespans and reduced frequency of replacement. Maintenance of ceramic membranes is generally less intensive due to higher resistance to fouling and aggressive cleaning protocols, enabling cost savings over time. In contrast, polymeric membranes demand more frequent maintenance and mild cleaning agents to prevent damage, which can lead to shorter operational lifespans and increased downtime.

Cost Considerations: Initial and Long-Term Investment

Ceramic membranes typically involve higher initial costs due to advanced materials and manufacturing processes but offer extended durability and resistance to harsh chemicals, reducing replacement frequency and long-term expenses. Polymeric membranes are generally more affordable upfront yet may incur increased operational costs from shorter lifespan and susceptibility to fouling and chemical degradation. Evaluating total cost of ownership involves balancing the premium price of ceramic membranes against the recurring expenses and maintenance required for polymeric alternatives.

Environmental Impact and Sustainability

Ceramic membranes exhibit superior environmental sustainability compared to polymeric membranes due to their longer lifespan, enhanced chemical resistance, and higher thermal stability, which significantly reduce waste and energy consumption during operation. Their ability to withstand aggressive cleaning agents and high temperatures allows for more efficient reuse and lower chemical usage, minimizing environmental pollution. In contrast, polymeric membranes typically degrade faster, require more frequent replacements, and often involve environmentally harmful manufacturing processes, making ceramic membranes a more sustainable choice for long-term water treatment applications.

Application Suitability: Choosing the Right Membrane

Ceramic membranes exhibit superior chemical and thermal resistance, making them ideal for harsh industrial applications such as wastewater treatment, food processing, and chemical separation. Polymeric membranes offer cost-effective solutions with high flexibility and are preferred for low-temperature processes like water purification and biopharmaceutical filtration. Selecting the appropriate membrane depends on operational conditions, including pH range, temperature, and chemical exposure, ensuring optimal performance and longevity.

Ceramic Membrane vs Polymeric Membrane Infographic

materialdif.com

materialdif.com