Porosity in ceramics refers to the volume of open spaces within the material that can affect strength and permeability, while vitrification describes the process where these pores are sealed as the ceramic becomes glass-like and non-porous. Higher vitrification results in lower porosity, enhancing the ceramic's durability, impermeability, and resistance to chemical attack. Controlling the balance between porosity and vitrification is critical for optimizing ceramic applications in both structural and functional contexts.

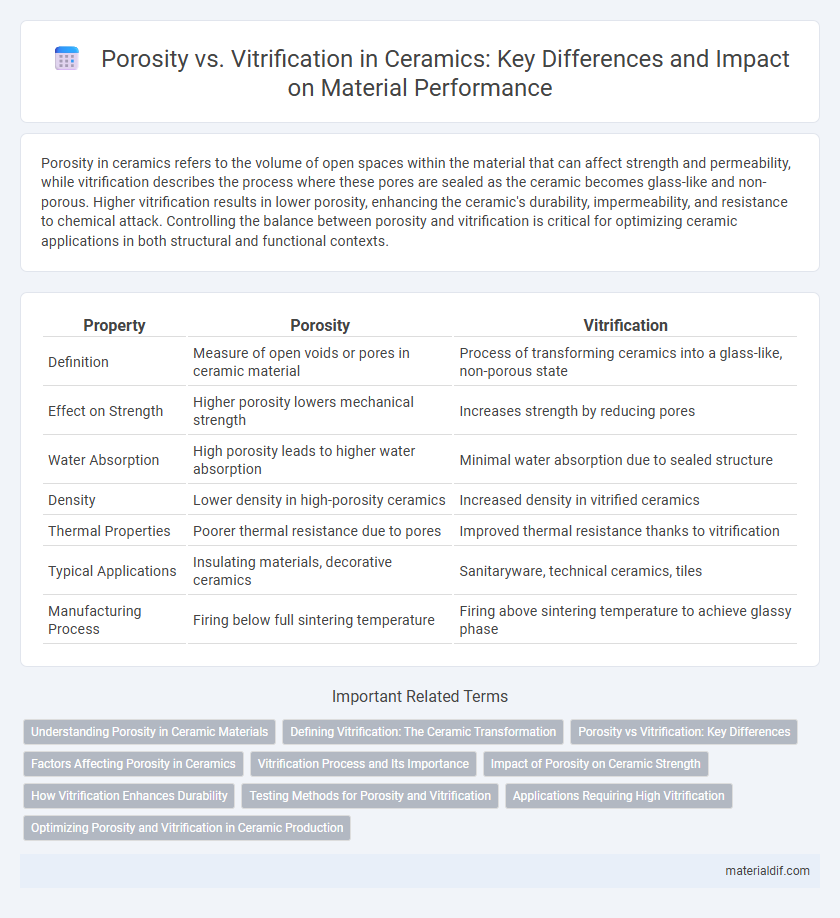

Table of Comparison

| Property | Porosity | Vitrification |

|---|---|---|

| Definition | Measure of open voids or pores in ceramic material | Process of transforming ceramics into a glass-like, non-porous state |

| Effect on Strength | Higher porosity lowers mechanical strength | Increases strength by reducing pores |

| Water Absorption | High porosity leads to higher water absorption | Minimal water absorption due to sealed structure |

| Density | Lower density in high-porosity ceramics | Increased density in vitrified ceramics |

| Thermal Properties | Poorer thermal resistance due to pores | Improved thermal resistance thanks to vitrification |

| Typical Applications | Insulating materials, decorative ceramics | Sanitaryware, technical ceramics, tiles |

| Manufacturing Process | Firing below full sintering temperature | Firing above sintering temperature to achieve glassy phase |

Understanding Porosity in Ceramic Materials

Porosity in ceramic materials refers to the presence of void spaces within the microstructure, which directly affects mechanical strength, thermal insulation, and durability. Higher porosity typically results in lower density and increased permeability, reducing the material's resistance to wear and moisture absorption. Controlling porosity through the sintering process influences the degree of vitrification, where increased vitrification reduces porosity by forming a glassy phase that enhances structural integrity.

Defining Vitrification: The Ceramic Transformation

Vitrification in ceramics refers to the process where clay particles melt and fuse together at high temperatures, resulting in a glass-like, non-porous structure. This transformation significantly reduces porosity by closing microscopic pores, enhancing the ceramic's strength, durability, and water resistance. Understanding vitrification is crucial for controlling the ceramic's final properties, especially in products like porcelain and stoneware where low porosity is desired.

Porosity vs Vitrification: Key Differences

Porosity in ceramics refers to the presence of tiny pores or voids within the material, directly affecting its strength, durability, and permeability, while vitrification is the process wherein ceramic materials transform into a glass-like, non-porous state through high-temperature firing. Porosity decreases as vitrification increases because vitrification causes the particles to fuse and fill gaps, resulting in reduced water absorption and enhanced mechanical properties. Understanding the key differences between porosity and vitrification is essential for controlling ceramic quality and performance in applications such as pottery, tiles, and advanced ceramic engineering.

Factors Affecting Porosity in Ceramics

Porosity in ceramics is primarily influenced by the raw material composition, particle size distribution, and firing temperature, which together determine the extent of vitrification and pore closure. Higher firing temperatures promote densification by enhancing glassy phase formation, thereby reducing porosity and increasing mechanical strength. The rate of heating and cooling, along with the presence of fluxes, also significantly affect the degree of vitrification and porous structure in the final ceramic product.

Vitrification Process and Its Importance

Vitrification is the process where ceramic materials are heated to a point that the particles fuse into a dense, glass-like structure, significantly reducing porosity. This transformation enhances strength, durability, and impermeability, making ceramics more resistant to water absorption and mechanical stress. Vitrification is crucial in producing high-quality ceramics for applications in tiles, sanitaryware, and advanced engineering materials.

Impact of Porosity on Ceramic Strength

Porosity in ceramics directly reduces material strength by creating voids that act as stress concentrators, weakening the overall structure. Higher porosity increases the risk of crack initiation and propagation, compromising both mechanical durability and fracture toughness. Vitrification decreases porosity by promoting liquid phase sintering, resulting in denser ceramics with enhanced strength and improved resistance to mechanical failure.

How Vitrification Enhances Durability

Vitrification in ceramics involves the transformation of raw materials into a glassy, non-porous matrix, significantly reducing porosity levels that typically allow water and contaminants to penetrate. This reduction in porosity enhances the ceramic's mechanical strength, resistance to abrasion, and chemical stability, making vitrified ceramics ideal for applications requiring high durability. The densification process during vitrification also minimizes the presence of micro-cracks, further improving the longevity and performance of ceramic products in harsh environments.

Testing Methods for Porosity and Vitrification

Testing methods for porosity in ceramics primarily include water absorption tests and mercury intrusion porosimetry, which quantify the volume and distribution of pores by measuring water uptake or mercury penetration under pressure. Vitrification assessment employs techniques such as differential thermal analysis (DTA) and x-ray diffraction (XRD) to evaluate the degree of glassy phase formation and crystalline transformations during firing. These methods together provide critical insights into ceramic density, durability, and thermal properties essential for optimizing material performance.

Applications Requiring High Vitrification

High vitrification is crucial in ceramic applications requiring enhanced durability and low porosity, such as advanced technical ceramics used in aerospace and biomedical implants. Achieving high vitrification reduces water absorption and increases mechanical strength, making materials ideal for harsh environments and structural components. Porcelain and stoneware exemplify ceramics with high vitrification, providing superior wear resistance and longevity in both industrial and domestic settings.

Optimizing Porosity and Vitrification in Ceramic Production

Optimizing porosity and vitrification in ceramic production requires precise control of firing temperature and clay composition to balance strength and permeability. Higher vitrification decreases porosity by creating a glassy phase that seals pores, improving durability and water resistance. Manufacturers adjust mineral content and firing schedules to achieve targeted porosity levels that enhance performance for specific applications like insulation or filtration.

Porosity vs Vitrification Infographic

materialdif.com

materialdif.com