Bisque firing transforms raw clay into durable, porous ceramic by heating it to a lower temperature, making it ready for glazing. Glaze firing follows, melting the glaze to create a smooth, glassy surface that seals and decorates the pottery. Understanding the distinct stages and temperature requirements of bisque and glaze firing ensures optimal strength and aesthetic quality in ceramics.

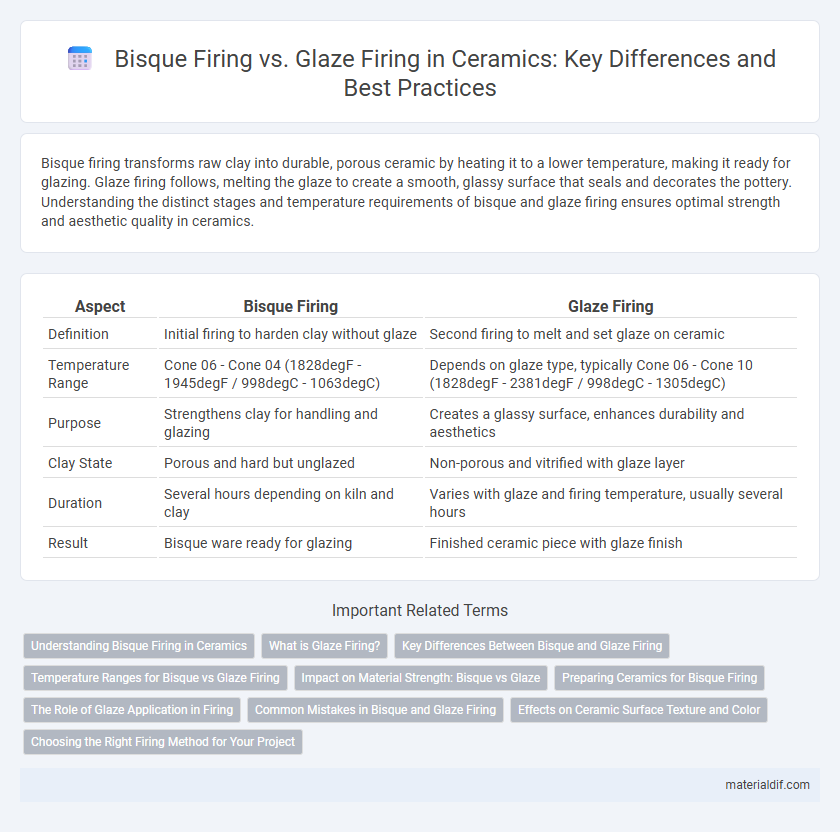

Table of Comparison

| Aspect | Bisque Firing | Glaze Firing |

|---|---|---|

| Definition | Initial firing to harden clay without glaze | Second firing to melt and set glaze on ceramic |

| Temperature Range | Cone 06 - Cone 04 (1828degF - 1945degF / 998degC - 1063degC) | Depends on glaze type, typically Cone 06 - Cone 10 (1828degF - 2381degF / 998degC - 1305degC) |

| Purpose | Strengthens clay for handling and glazing | Creates a glassy surface, enhances durability and aesthetics |

| Clay State | Porous and hard but unglazed | Non-porous and vitrified with glaze layer |

| Duration | Several hours depending on kiln and clay | Varies with glaze and firing temperature, usually several hours |

| Result | Bisque ware ready for glazing | Finished ceramic piece with glaze finish |

Understanding Bisque Firing in Ceramics

Bisque firing is the initial kiln process that hardens clay into a porous, durable state, preparing the ceramic piece for glazing without vitrifying the clay. This firing typically reaches temperatures between 1730degF and 1940degF (945degC to 1060degC), driving out moisture and organic materials while preserving the clay's absorbent qualities. Understanding bisque firing is crucial for achieving optimal glaze adhesion and preventing defects like cracking or warping during subsequent glaze firing.

What is Glaze Firing?

Glaze firing is the high-temperature process in ceramics that melts and fuses glaze materials onto the pottery surface, creating a glass-like, durable coating. This firing typically occurs after bisque firing and is essential for sealing the porous clay body, enhancing both aesthetics and functionality. The temperature range for glaze firing varies depending on the glaze composition but generally falls between 1,800degF and 2,400degF (982degC to 1,316degC).

Key Differences Between Bisque and Glaze Firing

Bisque firing transforms raw clay into a durable, porous state by heating it to approximately 1,800degF (980degC), removing moisture and organic material without fully vitrifying the piece. Glaze firing occurs at higher temperatures, typically between 2,100degF and 2,300degF (1,150degC to 1,260degC), where the glaze melts and fuses to the bisque ware, creating a glassy, waterproof surface. The key difference lies in bisque firing preparing the clay body for glaze application, while glaze firing finalizes the ceramic piece's strength and aesthetic finish.

Temperature Ranges for Bisque vs Glaze Firing

Bisque firing typically occurs at temperatures between 1,650degF and 1,830degF (900degC to 1,000degC), aiming to harden the ceramic clay without vitrification. Glaze firing requires higher temperatures, ranging from 1,832degF to 2,372degF (1,000degC to 1,300degC), to melt the glaze and form a glassy surface. The distinct temperature ranges ensure proper transformation of the clay body and glaze durability.

Impact on Material Strength: Bisque vs Glaze

Bisque firing transforms clay into a porous, durable state by driving out chemical water, significantly increasing the ceramic's mechanical strength and making it less fragile than raw clay. Glaze firing, conducted at higher temperatures, vitrifies the surface, creating a glass-like coating that enhances both strength and water resistance by sealing micro-cracks and reinforcing the ceramic's structural integrity. The combined firing process optimizes ceramic durability, with bisque firing providing foundational strength and glaze firing contributing surface hardness and protection against environmental factors.

Preparing Ceramics for Bisque Firing

Preparing ceramics for bisque firing involves thoroughly drying the clay pieces to remove all moisture, preventing cracking or explosions in the kiln. Ensuring even thickness and smooth surfaces helps achieve uniform heat distribution during firing. Proper cleaning of the ceramic surface removes dust and debris, which enhances glaze adherence in subsequent glaze firing stages.

The Role of Glaze Application in Firing

Glaze application transforms bisque-fired pottery by creating a glass-like surface during the glaze firing, sealing the porous clay body and enhancing durability. This process chemically alters the surface through vitrification, resulting in varied textures, colors, and finishes that bisque firing alone cannot achieve. Proper glaze formulation and even application are crucial for achieving optimal adhesion, aesthetic appeal, and functional performance in the final ceramic piece.

Common Mistakes in Bisque and Glaze Firing

Common mistakes in bisque firing include firing too quickly, causing thermal shock and cracking, or underfiring, which leaves the clay insufficiently hardened for glazing. During glaze firing, applying glaze too thickly can result in drips or blisters, while firing at incorrect temperatures may cause glaze defects like pinholing or crawling. Ensuring controlled heating rates and precise temperature targets is essential to avoid these typical bisque and glaze firing issues.

Effects on Ceramic Surface Texture and Color

Bisque firing transforms clay into a porous, matte surface that enhances glaze adhesion and preserves detailed textures, while glaze firing vitrifies the surface, creating a smooth, glass-like finish that intensifies colors and alters texture perception. The bisque stage solidifies the ceramic body without color changes, maintaining a rough texture ideal for glaze application, whereas glaze firing fuses the glaze to the ceramic, producing varied surface effects from glossy to matte and significantly deepening color richness. Understanding the distinct impacts of bisque and glaze firing on ceramic surface texture and color is essential for achieving desired artistic and functional outcomes in pottery and ceramic art.

Choosing the Right Firing Method for Your Project

Bisque firing is essential for transforming fragile clay into porous, durable ceramic ware ready to absorb glaze, while glaze firing vitrifies the glaze and clay body, creating a finished, waterproof surface. Choosing the right firing method depends on the project's requirements for durability, texture, and finish; bisque firing suits initial strengthening, whereas glaze firing completes the piece with functional and aesthetic qualities. Understanding kiln temperatures, typically around bisque firing at cone 06-04 (1828-1940degF) and glaze firing at cone 5-10 (2167-2345degF), guides artists in selecting the appropriate process for their ceramic works.

Bisque Firing vs Glaze Firing Infographic

materialdif.com

materialdif.com