Oxidation firing exposes ceramics to ample oxygen, resulting in brighter and more consistent colors due to complete combustion of gases. Reduction firing limits oxygen supply, creating a chemically reducing atmosphere that enhances metallic effects and deeper, richer glazes. The choice between oxidation and reduction firing significantly impacts the final texture, color, and surface finish of ceramic pieces.

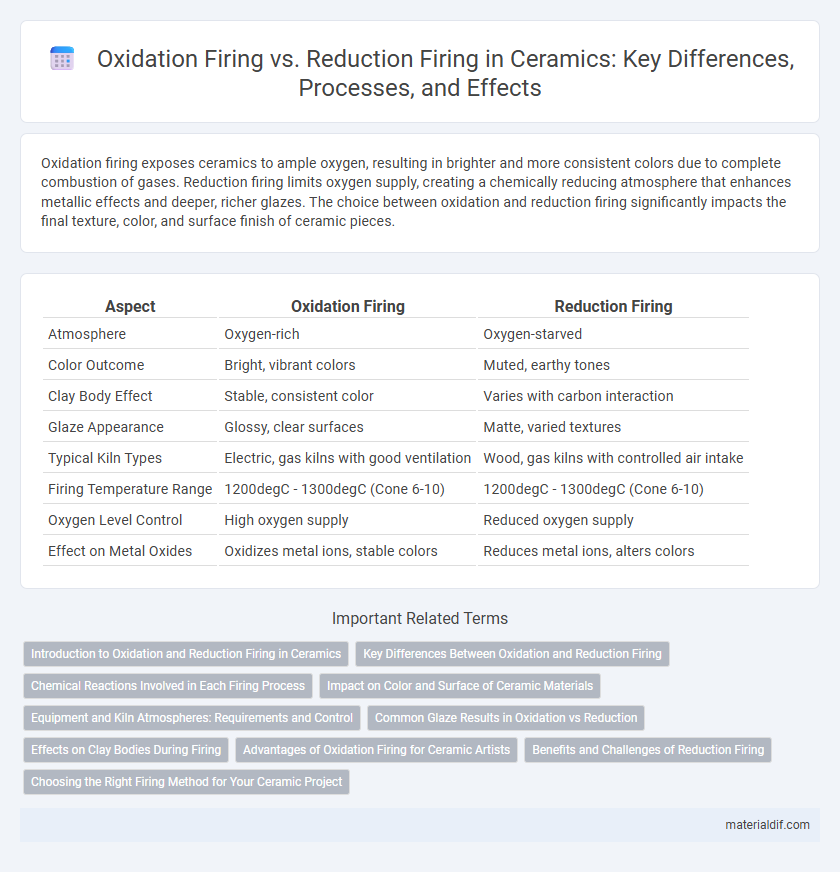

Table of Comparison

| Aspect | Oxidation Firing | Reduction Firing |

|---|---|---|

| Atmosphere | Oxygen-rich | Oxygen-starved |

| Color Outcome | Bright, vibrant colors | Muted, earthy tones |

| Clay Body Effect | Stable, consistent color | Varies with carbon interaction |

| Glaze Appearance | Glossy, clear surfaces | Matte, varied textures |

| Typical Kiln Types | Electric, gas kilns with good ventilation | Wood, gas kilns with controlled air intake |

| Firing Temperature Range | 1200degC - 1300degC (Cone 6-10) | 1200degC - 1300degC (Cone 6-10) |

| Oxygen Level Control | High oxygen supply | Reduced oxygen supply |

| Effect on Metal Oxides | Oxidizes metal ions, stable colors | Reduces metal ions, alters colors |

Introduction to Oxidation and Reduction Firing in Ceramics

Oxidation firing in ceramics occurs when oxygen is abundant in the kiln atmosphere, allowing metals like iron and copper to produce bright, vibrant glaze colors such as reds and blues. Reduction firing limits oxygen, causing metals to react differently and often producing richer, earthy tones like deep browns, greens, and black. Understanding the chemical reactions during oxidation and reduction firing is essential for controlling glaze outcomes and achieving desired ceramic surface effects.

Key Differences Between Oxidation and Reduction Firing

Oxidation firing involves an ample oxygen supply, resulting in brighter, more consistent colors and well-defined glaze finishes, while reduction firing limits oxygen to create unique effects like darker hues, metallic sheens, and varied surface textures. The chemical reactions during oxidation stabilize the clay and glaze compounds, enhancing durability and color vibrancy, whereas reduction firing alters the oxidation states of metal oxides, producing unpredictable and varied ceramic aesthetics. The choice between oxidation and reduction significantly influences the final appearance and structural properties of ceramics, making it crucial for potters to select the firing atmosphere based on desired artistic and functional outcomes.

Chemical Reactions Involved in Each Firing Process

Oxidation firing involves a chemical reaction where oxygen is abundant, allowing metal oxides in ceramics to fully oxidize, resulting in brighter, more stable colors and consistent surface textures. Reduction firing restricts oxygen supply, causing metal oxides to gain electrons and partially reduce, which can alter the color outcome by producing richer, varied hues and unique surface effects. These contrasting redox conditions directly affect the chemical composition and appearance of glaze and clay bodies through changes in oxide states such as iron, copper, and manganese.

Impact on Color and Surface of Ceramic Materials

Oxidation firing exposes ceramic materials to ample oxygen, producing bright, consistent colors and glossy surfaces by fully oxidizing metal oxides such as iron and copper. Reduction firing limits oxygen, creating a chemical environment that alters the metal oxides, often resulting in richer, muted colors and varied surface textures due to partial reduction reactions. Color outcomes in oxidation firing tend to be predictable and vibrant, while reduction firing yields unpredictable, complex hues and matte or textured finishes influenced by kiln atmosphere and firing duration.

Equipment and Kiln Atmospheres: Requirements and Control

Oxidation firing requires kilns with ample ventilation systems to supply continuous oxygen, maintaining an oxidizing atmosphere essential for bright, consistent glaze colors. Reduction firing demands specialized equipment capable of restricting oxygen flow, often utilizing gas kilns with precise fuel-air mixture controls to create a reducing atmosphere that alters oxide states and intensifies color variations. Sophisticated monitoring instruments such as oxygen sensors and programmable controllers optimize kiln atmosphere regulation, ensuring accurate temperature profiles and desired chemical reactions during both firing techniques.

Common Glaze Results in Oxidation vs Reduction

Oxidation firing exposes ceramics to ample oxygen, resulting in bright, clear, and consistent glaze colors such as reds, blues, and greens due to fully oxidized metal oxides. Reduction firing limits oxygen, creating rich, varied glaze effects with metallic sheens, deeper hues, and unique textures by transforming metal oxides into different chemical states. Common glaze results in oxidation often display crisp, predictable finishes while reduction produces unpredictable, complex surface variations favored for artistic expression.

Effects on Clay Bodies During Firing

Oxidation firing exposes clay bodies to ample oxygen, resulting in brighter and more consistent colors due to the full development of metal oxides, especially iron. Reduction firing limits oxygen, causing chemical changes in clay minerals that produce richer, darker tones and varied surface textures from altered iron and other metallic compounds. These contrasting atmospheres significantly influence the strength, porosity, and final aesthetic qualities of ceramic pieces.

Advantages of Oxidation Firing for Ceramic Artists

Oxidation firing exposes ceramics to ample oxygen, enhancing color vibrancy and ensuring consistent glaze finishes, crucial for detailed artistic expression. This firing method offers greater control over the kiln atmosphere, reducing defects such as pinholes and blistering for higher-quality results. Ceramic artists benefit from oxidation firing's predictability and the ability to achieve bright, crisp surface textures that elevate the visual appeal of their work.

Benefits and Challenges of Reduction Firing

Reduction firing enhances ceramic glazes by creating rich, complex colors and increased surface texture due to the limited oxygen environment altering metal oxides. This firing method benefits artists seeking unique aesthetic effects and increased durability but challenges include precise atmosphere control and longer kiln cycles, requiring advanced technical skill and experience. The unpredictability of color outcomes demands experimentation, making reduction firing less accessible for beginners compared to oxidation firing.

Choosing the Right Firing Method for Your Ceramic Project

Choosing the right firing method depends on the desired surface effects and clay body compatibility. Oxidation firing, performed in an oxygen-rich kiln environment, enhances bright, consistent colors and is ideal for stoneware and porcelain. Reduction firing limits oxygen, creating rich, varied hues and metallic finishes, making it suitable for achieving unique glaze textures and rustic aesthetics.

Oxidation Firing vs Reduction Firing Infographic

materialdif.com

materialdif.com