Raku firing involves removing ceramics from a hot kiln and placing them in combustible materials to create unique surface effects, resulting in vibrant colors and crackled textures. Pit firing, an ancient technique, uses a pit filled with organic materials and metal oxides to produce earthy, unpredictable patterns and smoky finishes on the ceramics. Both methods emphasize rapid cooling and atmospheric interactions, but raku offers more control over the oxidation process compared to the spontaneous nature of pit firing.

Table of Comparison

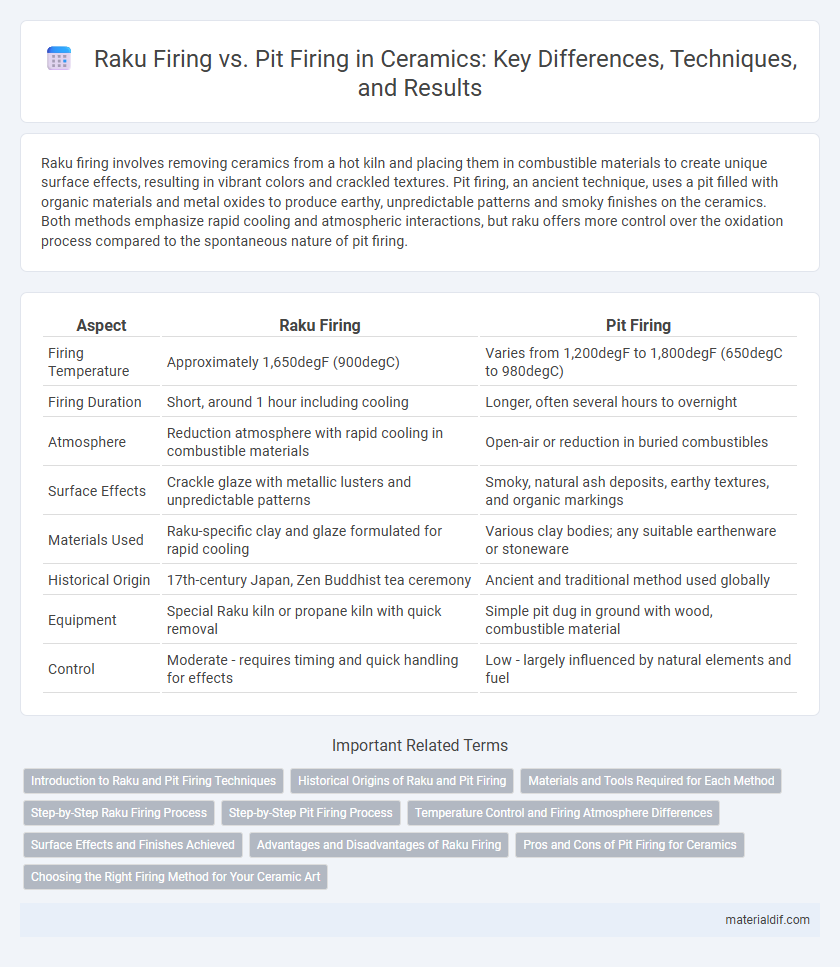

| Aspect | Raku Firing | Pit Firing |

|---|---|---|

| Firing Temperature | Approximately 1,650degF (900degC) | Varies from 1,200degF to 1,800degF (650degC to 980degC) |

| Firing Duration | Short, around 1 hour including cooling | Longer, often several hours to overnight |

| Atmosphere | Reduction atmosphere with rapid cooling in combustible materials | Open-air or reduction in buried combustibles |

| Surface Effects | Crackle glaze with metallic lusters and unpredictable patterns | Smoky, natural ash deposits, earthy textures, and organic markings |

| Materials Used | Raku-specific clay and glaze formulated for rapid cooling | Various clay bodies; any suitable earthenware or stoneware |

| Historical Origin | 17th-century Japan, Zen Buddhist tea ceremony | Ancient and traditional method used globally |

| Equipment | Special Raku kiln or propane kiln with quick removal | Simple pit dug in ground with wood, combustible material |

| Control | Moderate - requires timing and quick handling for effects | Low - largely influenced by natural elements and fuel |

Introduction to Raku and Pit Firing Techniques

Raku firing is a Japanese ceramic technique involving rapid heating and cooling, producing distinctive crackled glazes and metallic effects through reduction processes. Pit firing is an ancient method where ceramics are placed in a pit kiln with combustible materials, resulting in varied surface textures and colorations from smoke and flame interaction. Both techniques emphasize unpredictability and organic finishes, appealing to artists seeking unique, handcrafted aesthetics.

Historical Origins of Raku and Pit Firing

Raku firing originated in 16th-century Japan, renowned for its unique technique of removing pottery from the kiln while glowing hot, creating distinct crackled glazes and smoky effects. Pit firing, one of the oldest ceramic firing methods, dates back thousands of years and involves placing pottery in a pit with combustible materials, generating organic patterns from ash and flame interaction. Both techniques reflect ancient cultural practices but differ significantly in process and aesthetic outcomes, with Raku tied to Japanese tea ceremonies and Pit firing rooted in prehistoric craftsmanship worldwide.

Materials and Tools Required for Each Method

Raku firing requires a kiln capable of reaching rapid high temperatures and specialized raku glazes that crackle during cooling, alongside tongs and protective gear for quick removal and reduction in combustible materials like sawdust or newspaper. Pit firing utilizes an open pit or metal container, combustible materials such as wood, leaves, and salt, and simple tools like shovels and metal tongs to control the placement and removal of ceramics. The material differences highlight raku's dependence on a controlled kiln environment, while pit firing relies on organic fuel sources and open-air combustion for surface effects.

Step-by-Step Raku Firing Process

Raku firing involves a rapid heating process where ceramic pieces are removed from the kiln at bright red heat and placed into combustible materials to create unique surface effects through rapid cooling and reduction. The step-by-step process begins with bisque firing the pottery, followed by heating in a raku kiln until the desired temperature, typically around 1,650degF (900degC), is reached. After extraction with tongs, the hot piece is placed in a reduction chamber--such as a container filled with sawdust or newspaper--where smoke interacts with the clay, producing distinctive metallic and crackled finishes that differ significantly from the slower, buried method in pit firing.

Step-by-Step Pit Firing Process

Pit firing involves placing ceramics in a shallow pit layered with combustible materials like wood, sawdust, and organic matter, followed by lighting the materials to create intense heat. The process requires careful layering of ceramics and fuel, monitoring the firing temperature, and allowing gradual cooling to avoid cracking. This traditional firing technique produces unique surface effects, such as smoky patterns and earthy textures, distinct from the unpredictable results of Raku firing.

Temperature Control and Firing Atmosphere Differences

Raku firing operates at rapid cooling temperatures typically between 1,650degF to 1,830degF, allowing precise temperature control to achieve metallic lusters and crackle effects, while pit firing reaches lower temperatures around 1,200degF to 1,600degF with less control, yielding earthy surface textures. The firing atmosphere in Raku involves rapid oxidation and reduction during post-firing reduction chambers, intensifying glaze colors and surface variations; pit firing uses natural combustibles like wood or organic materials, creating unpredictable smoky patterns and carbonized marks. These fundamental differences impact the clay body's thermal shock resistance and the ceramic's final aesthetic qualities, with Raku favoring delicate, reactive finishes and pit firing emphasizing rustic, organic aesthetics.

Surface Effects and Finishes Achieved

Raku firing produces unique crackled glaze surfaces and metallic lusters due to rapid cooling and reduction atmospheres, creating unpredictable and dramatic finishes. Pit firing results in earthy, smoky textures with natural ash deposits and organic patterns from combusted materials, offering a rustic and varied surface. Both techniques highlight distinct aesthetic qualities: raku emphasizes vibrant, iridescent effects, while pit firing delivers raw, textured finishes with deep, smoky coloration.

Advantages and Disadvantages of Raku Firing

Raku firing offers rapid heat cycling that produces unique crackle patterns and vibrant glazes, making each ceramic piece distinct and artistically appealing. It requires less fuel and time compared to pit firing, enhancing efficiency but involves thermal shock that can cause fragility or cracks in the ceramic body. While raku provides dynamic surface effects and artistic control, its unpredictability and reduced structural strength limit its use for functional ware.

Pros and Cons of Pit Firing for Ceramics

Pit firing offers unique surface textures and unpredictable color variations, enhancing the artistic character of ceramics while being an affordable and traditional firing method. However, it presents challenges such as limited temperature control, resulting in less durability and inconsistent firing outcomes compared to electric or gas kiln firings. The environmental exposure during pit firing can also introduce contaminants and requires careful monitoring of fuel materials to avoid toxic emissions.

Choosing the Right Firing Method for Your Ceramic Art

Raku firing offers rapid cooling and unique crackle effects, ideal for artists seeking spontaneous texture and vibrant glaze variations in their ceramic art. Pit firing provides a primitive, earthy aesthetic through natural materials like wood and carbon, perfect for artists who value traditional, organic finishes and subtle color shifts. Selecting the right firing method depends on the desired surface quality, firing duration, and artistic intent, with Raku suited for bold, experimental pieces and Pit firing for rustic, historical styles.

Raku Firing vs Pit Firing Infographic

materialdif.com

materialdif.com