Slip casting involves pouring liquid clay slip into plaster molds to form intricate ceramic shapes with high detail and smooth surfaces. Press molding uses manual or mechanical pressure to shape clay within a mold, offering faster production and ideal for simpler, thicker forms. Choosing between slip casting and press molding depends on the desired precision, texture, and volume of ceramic pieces.

Table of Comparison

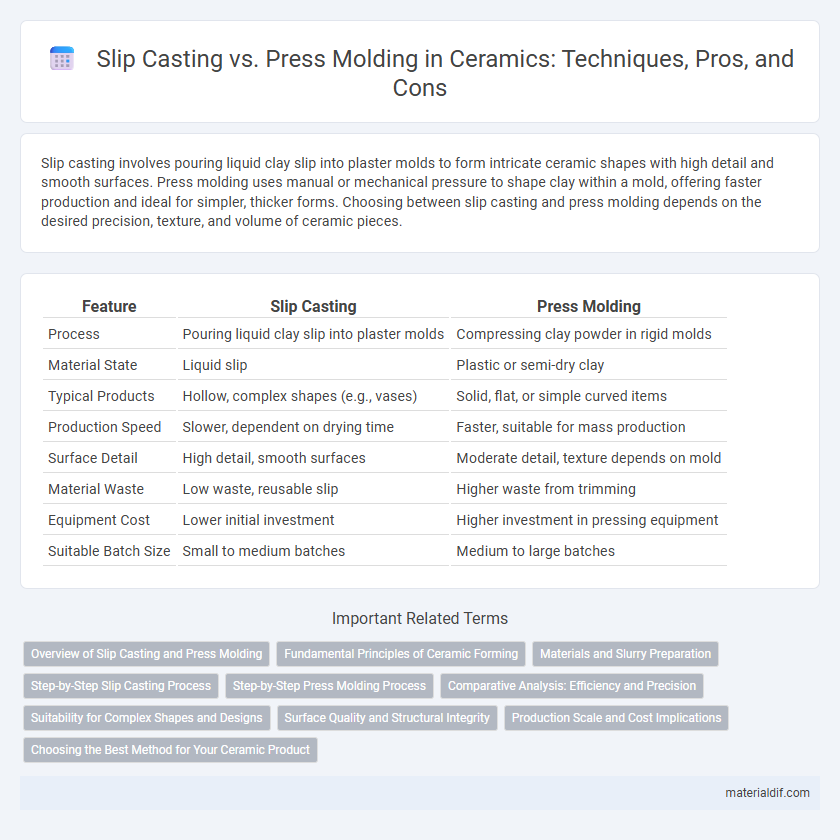

| Feature | Slip Casting | Press Molding |

|---|---|---|

| Process | Pouring liquid clay slip into plaster molds | Compressing clay powder in rigid molds |

| Material State | Liquid slip | Plastic or semi-dry clay |

| Typical Products | Hollow, complex shapes (e.g., vases) | Solid, flat, or simple curved items |

| Production Speed | Slower, dependent on drying time | Faster, suitable for mass production |

| Surface Detail | High detail, smooth surfaces | Moderate detail, texture depends on mold |

| Material Waste | Low waste, reusable slip | Higher waste from trimming |

| Equipment Cost | Lower initial investment | Higher investment in pressing equipment |

| Suitable Batch Size | Small to medium batches | Medium to large batches |

Overview of Slip Casting and Press Molding

Slip casting involves pouring a liquid clay slip into a plaster mold, allowing water to be absorbed and forming a solid ceramic shell; it is ideal for producing complex shapes and hollow forms with fine details. Press molding uses direct pressure to shape clay against a mold surface, offering faster production and consistent thickness, suited for simpler, flat, or slightly curved ceramic parts. Both techniques are essential in ceramic manufacturing, with slip casting favoring intricacy and press molding emphasizing speed and uniformity.

Fundamental Principles of Ceramic Forming

Slip casting involves pouring a liquid clay slurry, or slip, into a porous mold where water absorption causes the clay to solidify against the mold walls, forming a hollow ceramic piece. Press molding uses dry or semi-dry clay pressed into a rigid mold, relying on mechanical pressure to shape the ceramic material with precise dimensions. Both methods optimize shaping by controlling moisture content and mold interaction, fundamental to achieving desired ceramic properties and structural integrity.

Materials and Slurry Preparation

Slip casting utilizes a liquid clay slurry, composed of finely ground ceramic particles suspended in water, requiring precise control of viscosity and particle size distribution to ensure uniform mold filling. Press molding employs a more plastic, clay-based material with limited moisture content, optimized for high compactness and minimal shrinkage through direct mechanical pressing. Material selection in slip casting favors fine, deflocculated slips for fluidity, while press molding relies on cohesive, high-plasticity bodies for shape retention and green strength.

Step-by-Step Slip Casting Process

The step-by-step slip casting process begins with preparing a liquid clay slip, which is poured into a porous plaster mold that absorbs water, causing the slip to solidify against the mold walls. Once the desired thickness is achieved, excess slip is drained, and the mold is left to dry partially before carefully removing the cast ceramic piece. The process concludes with drying the greenware further before firing it in a kiln to produce the final ceramic product.

Step-by-Step Press Molding Process

Press molding in ceramics involves compacting clay or slip into a pre-shaped mold using high pressure to ensure precise form and density. The process begins by preparing the ceramic material to a plastic consistency, followed by placing it carefully into a mold cavity. Once filled, mechanical or hydraulic presses apply uniform pressure, solidifying the shape before the molded piece is demolded and dried for subsequent firing.

Comparative Analysis: Efficiency and Precision

Slip casting offers superior precision in complex shapes due to its ability to create uniform thin walls, whereas press molding excels in efficiency for high-volume production with consistent, thicker forms. The efficiency of press molding stems from faster cycle times and less material waste, while slip casting requires longer drying periods but allows for finer detail and smoother surface finishes. When balancing precision and production speed, slip casting is ideal for intricate, low-volume designs, whereas press molding suits large-scale manufacturing with simpler geometries.

Suitability for Complex Shapes and Designs

Slip casting excels in creating intricate and complex ceramic shapes due to its use of liquid clay that flows into detailed molds, capturing fine textures and delicate features with high precision. Press molding, while effective for simpler, repetitive forms, struggles with undercuts and elaborate designs because it requires solid clay to be pressed into rigid molds, limiting its adaptability. For artisans prioritizing complex geometries and detailed surface patterns, slip casting is the more suitable technique.

Surface Quality and Structural Integrity

Slip casting produces ceramics with smooth, uniform surfaces ideal for intricate designs, while press molding often results in denser, more structurally robust pieces with slight surface texture variations. The controlled flow of liquid clay in slip casting enhances surface detail and reduces defects, whereas press molding compresses powdered clay, improving mechanical strength but sometimes producing minor surface imperfections. Selection depends on whether superior surface finish or maximum structural integrity holds greater priority in the final ceramic product.

Production Scale and Cost Implications

Slip casting offers greater flexibility for small to medium production scales due to lower initial mold costs and ease of mold modification, making it suitable for custom or limited runs. Press molding, with higher upfront investment in durable molds, is optimized for large-scale production, providing faster cycle times and consistent quality that reduce cost per unit over time. Choosing between slip casting and press molding depends on balancing production volume demands against initial tooling expenses and long-term cost efficiency.

Choosing the Best Method for Your Ceramic Product

Slip casting offers superior precision and complex shapes by pouring liquid clay into plaster molds, ideal for intricate ceramic designs and small-batch production. Press molding provides faster production rates and durability by compressing clay into reusable molds, making it suitable for high-volume runs of simpler forms. Selecting the best method depends on your product's design complexity, production scale, and desired surface finish.

Slip Casting vs Press Molding Infographic

materialdif.com

materialdif.com