Microcrystalline wax is a flexible, fine-textured wax derived from petroleum refining, known for its excellent adhesive properties and moisture barrier. Montan wax, extracted from lignite coal, offers higher hardness and melting point, making it ideal for polishes, coatings, and industrial applications requiring durability. Both waxes serve distinct functions in cosmetics and manufacturing due to their unique chemical compositions and physical characteristics.

Table of Comparison

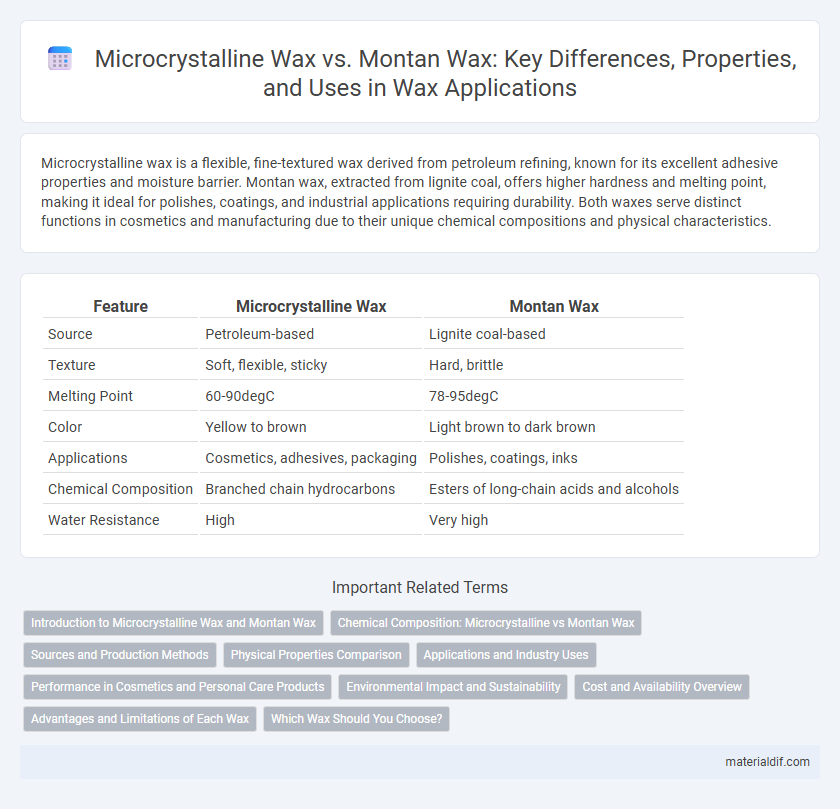

| Feature | Microcrystalline Wax | Montan Wax |

|---|---|---|

| Source | Petroleum-based | Lignite coal-based |

| Texture | Soft, flexible, sticky | Hard, brittle |

| Melting Point | 60-90degC | 78-95degC |

| Color | Yellow to brown | Light brown to dark brown |

| Applications | Cosmetics, adhesives, packaging | Polishes, coatings, inks |

| Chemical Composition | Branched chain hydrocarbons | Esters of long-chain acids and alcohols |

| Water Resistance | High | Very high |

Introduction to Microcrystalline Wax and Montan Wax

Microcrystalline wax is a petroleum-derived wax known for its fine crystals, flexibility, and high melting point, commonly used in cosmetics, adhesives, and coatings. Montan wax is a natural fossil wax extracted from lignite coal, valued for its hardness, resistance to acids, and excellent polishing properties in industrial applications. Both waxes serve distinct purposes based on their origin, composition, and physical characteristics.

Chemical Composition: Microcrystalline vs Montan Wax

Microcrystalline wax consists primarily of branched and cyclic hydrocarbons, typically having a carbon chain length between C30 and C70, resulting in a flexible and adhesive texture. Montan wax is derived from lignite coal and contains long-chain esters, free acids, and alcohols, with carbon chains generally ranging from C24 to C36, providing hardness and high melting points. The distinct chemical compositions influence microcrystalline wax's pliability and montan wax's durability and resistance to heat.

Sources and Production Methods

Microcrystalline wax is derived from the refining of petroleum residues, utilizing solvent dewaxing to isolate its fine crystalline structure, resulting in a wax with a higher molecular weight and flexibility. Montan wax is extracted from lignite, a type of brown coal, through a solvent extraction process, followed by refining to produce a hard, high-melting-point wax rich in long-chain fatty acids and esters. The distinct sources and production methods influence their physical properties and applications, with microcrystalline wax being more pliable and montan wax offering greater hardness and resistance.

Physical Properties Comparison

Microcrystalline wax exhibits a finer crystal structure with greater flexibility and higher tackiness compared to Montan wax, which is harder and more brittle due to its larger crystal size. Montan wax has a higher melting point, typically between 80-95degC, whereas microcrystalline wax melts at around 60-80degC, making it more suitable for applications requiring elasticity. The density of Montan wax ranges from 0.97 to 1.01 g/cm3, slightly higher than microcrystalline wax, which typically falls between 0.90 to 0.93 g/cm3.

Applications and Industry Uses

Microcrystalline wax is widely used in cosmetics, adhesives, and food packaging due to its flexibility, fine crystal structure, and excellent barrier properties. Montan wax finds primary applications in polishes, carbon paper, and coatings because of its hardness, high melting point, and superior water resistance. Industries such as automotive, electronics, and printing benefit from selecting the appropriate wax based on performance requirements and application-specific characteristics.

Performance in Cosmetics and Personal Care Products

Microcrystalline wax offers enhanced flexibility and adhesion properties, making it ideal for lip balms and creams requiring smooth texture and extended wear. Montan wax provides superior hardness and gloss, which benefits products like lipsticks and eyeliners that demand durability and shine. Both waxes deliver unique performance attributes, with microcrystalline excelling in moisture retention and montan wax improving product structure and visual appeal.

Environmental Impact and Sustainability

Microcrystalline wax, derived from petroleum refining, tends to have a larger environmental footprint due to fossil fuel extraction and non-renewable resource use, whereas Montan wax is obtained from lignite coal, a fossil material, but often involves lower emissions in processing. Both waxes present sustainability challenges, but Montan wax's natural origin can offer some biodegradability advantages compared to synthetic microcrystalline wax. Evaluating factors such as lifecycle carbon emissions, renewability of raw materials, and biodegradability is critical when assessing their environmental impact for eco-conscious applications.

Cost and Availability Overview

Microcrystalline wax generally offers lower cost and wider availability compared to Montan wax, which is derived from lignite coal and tends to be more expensive due to limited sources and complex extraction processes. Industrial suppliers commonly stock microcrystalline wax for applications like cosmetics and adhesives, while Montan wax's niche usage in specialty coatings and polishes leads to sporadic supply and higher market prices. Businesses favor microcrystalline wax for bulk procurement given its stable pricing and consistent availability worldwide.

Advantages and Limitations of Each Wax

Microcrystalline wax offers superior flexibility and higher melting points, making it ideal for applications requiring durability and resistance to cracking, but it tends to be more expensive and less transparent than other waxes. Montan wax excels in hardness and gloss, providing excellent polish and abrasion resistance for coatings and polishes, though it is less flexible and can be brittle under low temperatures. Both waxes serve distinct industrial purposes, with microcrystalline wax preferred for cosmetics and adhesives, while montan wax is favored in metal polishing and carbon paper manufacturing.

Which Wax Should You Choose?

Microcrystalline wax features a finer crystal structure and higher plasticity, making it ideal for flexible, detailed applications such as cosmetics and adhesives. Montan wax, derived from lignite coal, offers a higher melting point and greater hardness, suitable for industrial uses like coatings and polishes. Choosing between microcrystalline and montan wax depends on the required flexibility, melting point, and application-specific properties.

Microcrystalline Wax vs Montan Wax Infographic

materialdif.com

materialdif.com