Cosmetic grade wax is refined to meet strict purity standards, ensuring it is safe and non-toxic for use on the skin in products like lip balms, lotions, and makeup. Industrial grade wax contains impurities and additives that make it suitable for applications such as manufacturing, sealing, and coatings, but it is not safe for direct skin contact. Choosing the appropriate wax grade is essential to maintaining product safety, performance, and compliance with regulatory standards.

Table of Comparison

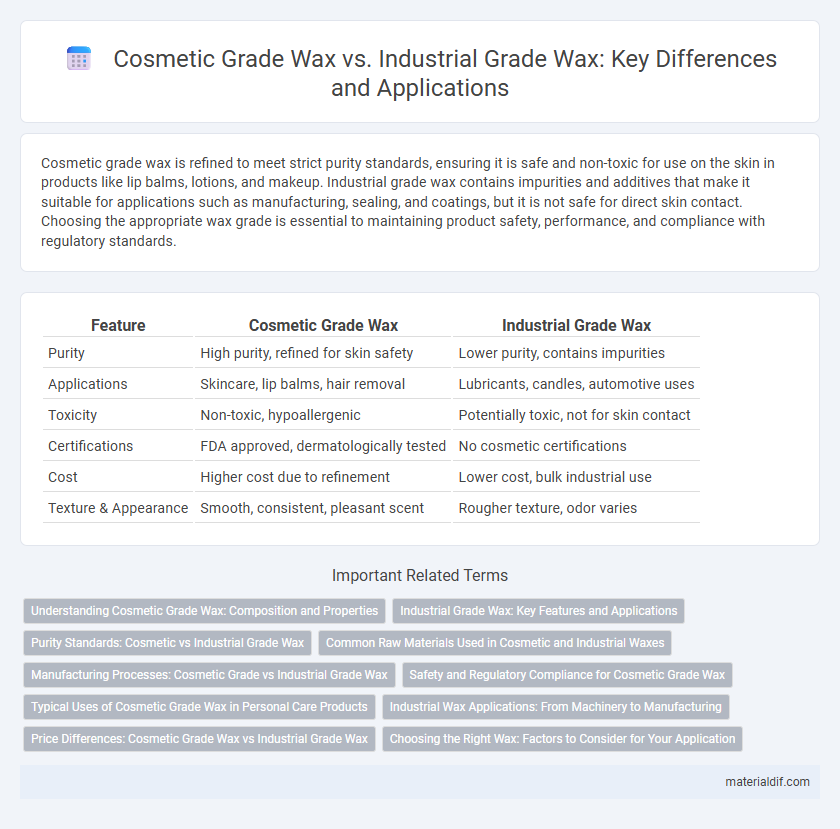

| Feature | Cosmetic Grade Wax | Industrial Grade Wax |

|---|---|---|

| Purity | High purity, refined for skin safety | Lower purity, contains impurities |

| Applications | Skincare, lip balms, hair removal | Lubricants, candles, automotive uses |

| Toxicity | Non-toxic, hypoallergenic | Potentially toxic, not for skin contact |

| Certifications | FDA approved, dermatologically tested | No cosmetic certifications |

| Cost | Higher cost due to refinement | Lower cost, bulk industrial use |

| Texture & Appearance | Smooth, consistent, pleasant scent | Rougher texture, odor varies |

Understanding Cosmetic Grade Wax: Composition and Properties

Cosmetic grade wax is formulated with high-purity ingredients to ensure safety and skin compatibility, featuring natural waxes like beeswax, carnauba, and candelilla that provide moisturizing and protective properties. Its refined composition excludes contaminants and additives present in industrial grade wax, resulting in consistent texture and melting points ideal for cosmetics. The precise physicochemical properties of cosmetic grade wax enhance product stability, spreadability, and skin adherence, making it essential for lip balms, creams, and lotions.

Industrial Grade Wax: Key Features and Applications

Industrial grade wax is characterized by its high melting point, excellent hardness, and superior abrasion resistance, making it suitable for heavy-duty applications. It is commonly used in manufacturing processes such as metal polishing, printing inks, rubber compounding, and adhesives due to its durability and chemical stability. Unlike cosmetic grade wax, industrial wax often contains additives tailored to enhance performance in mechanical and chemical environments.

Purity Standards: Cosmetic vs Industrial Grade Wax

Cosmetic grade wax adheres to stringent purity standards, ensuring it is free from harmful contaminants and safe for direct skin contact in products like lip balms and creams. Industrial grade wax typically contains impurities and additives that make it unsuitable for personal care applications but ideal for manufacturing, lubrication, or coating purposes. Regulatory bodies enforce higher purity guidelines for cosmetic grade wax to meet safety requirements in the beauty industry.

Common Raw Materials Used in Cosmetic and Industrial Waxes

Common raw materials used in cosmetic grade wax include beeswax, carnauba wax, candelilla wax, and synthetic derivatives like microcrystalline wax, prized for their purity and skin compatibility. Industrial grade waxes typically consist of paraffin wax, polyethylene wax, Fischer-Tropsch wax, and slack wax, chosen for durability, melting point, and cost-effectiveness in manufacturing processes. Understanding the distinct raw material composition highlights the safety and performance requirements specific to cosmetic applications versus industrial uses.

Manufacturing Processes: Cosmetic Grade vs Industrial Grade Wax

Cosmetic grade wax undergoes stringent purification and refining processes to ensure hypoallergenic, non-toxic properties suitable for skin contact in products like lip balms and lotions. Industrial grade wax is processed primarily for functionality and durability, with less emphasis on purity, often involving additives to enhance performance in applications such as coatings and adhesives. The manufacturing of cosmetic wax requires compliance with rigorous safety standards and testing protocols, while industrial wax focuses on cost-efficiency and bulk production methods.

Safety and Regulatory Compliance for Cosmetic Grade Wax

Cosmetic grade wax undergoes rigorous testing to meet safety standards set by regulatory bodies such as the FDA and EU Cosmetics Regulation, ensuring it is free from harmful contaminants and suitable for direct skin contact. It is formulated to be hypoallergenic, non-toxic, and compliant with strict purity criteria, minimizing risks of irritation or adverse reactions in cosmetic applications. Industrial grade wax lacks these stringent safety certifications, often containing impurities that make it unsuitable and unsafe for use in personal care and cosmetic products.

Typical Uses of Cosmetic Grade Wax in Personal Care Products

Cosmetic grade wax is primarily used in personal care products such as lip balms, lotions, creams, and hair styling products due to its high purity and skin-safe formulation. It provides essential moisturizing properties, enhances texture, and acts as a natural emollient, ensuring product stability and smooth application. Common examples include beeswax, carnauba wax, and candelilla wax, which are favored for their hypoallergenic and non-comedogenic qualities.

Industrial Wax Applications: From Machinery to Manufacturing

Industrial grade wax plays a crucial role in machinery lubrication, reducing friction and wear in heavy equipment and automotive parts. It is extensively used in manufacturing processes such as coating, molding, and sealing to enhance product durability and performance. Industries including electronics, packaging, and pharmaceuticals rely on industrial wax for its thermal stability and protective properties in production environments.

Price Differences: Cosmetic Grade Wax vs Industrial Grade Wax

Cosmetic grade wax typically commands a higher price than industrial grade wax due to its refined purity and stringent safety standards required for skin application. Industrial grade wax is more affordable because it contains more impurities and is manufactured without the rigorous quality controls necessary for cosmetic use. The price disparity reflects the additional processing, certification, and testing involved in producing cosmetic grade wax suitable for sensitive skin products.

Choosing the Right Wax: Factors to Consider for Your Application

Choosing the right wax depends on factors like purity, melting point, and intended use; cosmetic grade wax offers higher purity and skin-safe formulations ideal for personal care products, while industrial grade wax prioritizes cost-efficiency and durability for manufacturing processes. Consider formulation requirements, regulatory standards, and potential skin sensitivity when selecting between cosmetic and industrial waxes to ensure product safety and performance. Evaluating these criteria helps optimize functionality and compliance in applications ranging from candles and lotions to coatings and adhesives.

Cosmetic Grade Wax vs Industrial Grade Wax Infographic

materialdif.com

materialdif.com