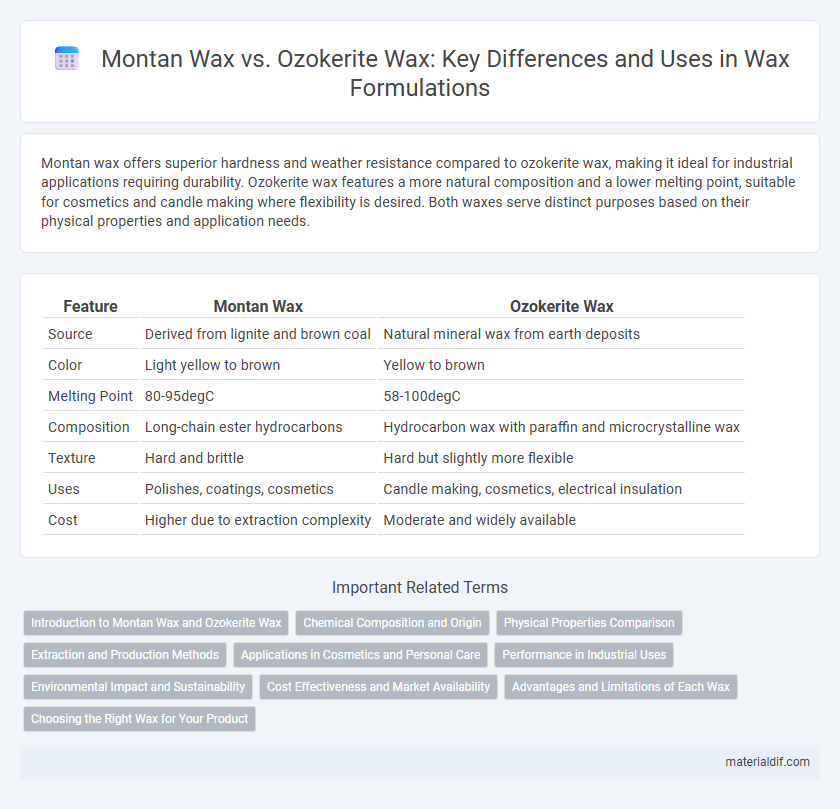

Montan wax offers superior hardness and weather resistance compared to ozokerite wax, making it ideal for industrial applications requiring durability. Ozokerite wax features a more natural composition and a lower melting point, suitable for cosmetics and candle making where flexibility is desired. Both waxes serve distinct purposes based on their physical properties and application needs.

Table of Comparison

| Feature | Montan Wax | Ozokerite Wax |

|---|---|---|

| Source | Derived from lignite and brown coal | Natural mineral wax from earth deposits |

| Color | Light yellow to brown | Yellow to brown |

| Melting Point | 80-95degC | 58-100degC |

| Composition | Long-chain ester hydrocarbons | Hydrocarbon wax with paraffin and microcrystalline wax |

| Texture | Hard and brittle | Hard but slightly more flexible |

| Uses | Polishes, coatings, cosmetics | Candle making, cosmetics, electrical insulation |

| Cost | Higher due to extraction complexity | Moderate and widely available |

Introduction to Montan Wax and Ozokerite Wax

Montan wax is a natural mineral wax derived from lignite or brown coal, characterized by its high melting point and excellent hardness, making it ideal for coatings, polishes, and cosmetics. Ozokerite wax, a naturally occurring mineral wax extracted through mining, features a lower melting point and softer texture, commonly used in candles, adhesives, and cosmetics. Both waxes are valued for their unique chemical compositions, with Montan wax containing long-chain acids and esters, while Ozokerite consists primarily of hydrocarbons.

Chemical Composition and Origin

Montan wax is derived from lignite coal and consists mainly of long-chain hydrocarbons, esters, and acids, providing high melting points and excellent polish properties. Ozokerite wax originates from mineral sources, specifically fossilized petroleum deposits, and contains a complex mix of alkanes, ceresin, and microcrystalline wax components with slightly lower melting points. The differing chemical compositions influence their industrial applications, with Montan wax favored for durability and gloss, while Ozokerite wax is valued for flexibility and adhesion.

Physical Properties Comparison

Montan wax exhibits a high melting point ranging from 82 to 95degC, making it harder and more brittle compared to ozokerite wax, which melts between 58 and 100degC but typically falls within a lower range. Montan wax has a higher acid value, usually between 15 and 30 mg KOH/g, reflecting its greater natural resin content, whereas ozokerite wax usually has a lower acid value around 5 to 20 mg KOH/g. The density of Montan wax is approximately 1.04 g/cm3, slightly higher than ozokerite wax's density of about 0.87 to 0.95 g/cm3.

Extraction and Production Methods

Montan wax is extracted from lignite coal through solvent refinement, involving a careful separation of wax components during coal processing. Ozokerite wax is a naturally occurring mineral wax mined from earth deposits, followed by purification through melting and filtration to remove impurities. The production of Montan wax is more industrial and chemical-intensive, while Ozokerite wax relies on physical mining and refining techniques.

Applications in Cosmetics and Personal Care

Montan wax, derived from lignite coal, offers superior film-forming properties and excellent gloss, making it ideal for lipsticks, mascaras, and nail polishes in cosmetics. Ozokerite wax, a naturally occurring mineral wax, is favored for its high melting point and rigidity, providing structural stability in creams, balms, and stick applicators. Both waxes enhance texture and durability in personal care products, but Montan wax excels in sheen and spreadability, while Ozokerite contributes to firmness and thermal resistance.

Performance in Industrial Uses

Montan wax offers superior hardness and high melting point, making it ideal for industrial applications requiring durability and thermal stability. Ozokerite wax provides excellent plasticity and adhesion, performing well in flexible coatings and electrical insulation. Both waxes excel in different industrial uses, with Montan wax favored for abrasive-resistant surfaces and Ozokerite for mold release agents and sealants.

Environmental Impact and Sustainability

Montan wax, derived from lignite coal, offers high biodegradability and a lower environmental footprint compared to ozokerite wax, which is a mineral wax obtained from petroleum with limited biodegradability. Montan wax production involves sustainable extraction practices that minimize ecosystem disruption, whereas ozokerite mining can lead to significant habitat degradation and increased greenhouse gas emissions. Choosing Montan wax supports environmental sustainability goals through reduced pollution and enhanced resource renewability.

Cost Effectiveness and Market Availability

Montan wax offers higher cost-effectiveness than ozokerite wax due to its superior durability and lower processing costs, making it a preferred choice in industrial applications. Ozokerite wax has limited market availability as a natural mineral wax, leading to variable pricing and supply constraints. Montan wax's consistent quality and broader availability enhance its appeal in manufacturing sectors requiring reliable and affordable wax materials.

Advantages and Limitations of Each Wax

Montan wax offers superior hardness and excellent polishability, making it ideal for high-quality coatings and polishes, but it can be more expensive and less flexible compared to ozokerite wax. Ozokerite wax is valued for its affordability and good binding properties in candle making and cosmetics, though it has lower melting points and reduced durability under heat stress. Both waxes serve distinct industrial purposes, with Montan wax excelling in durability and finish, while ozokerite provides cost-effective versatility.

Choosing the Right Wax for Your Product

Montan wax offers superior hardness and gloss, making it ideal for high-quality coatings, polishes, and cosmetics that require durability and a smooth finish. Ozokerite wax, with its lower melting point and pliability, suits applications like candles and adhesives where flexibility and ease of processing are essential. Selecting the right wax depends on product requirements such as melting point, hardness, and compatibility with oils or resins.

Montan Wax vs Ozokerite Wax Infographic

materialdif.com

materialdif.com