Fully refined paraffin wax undergoes extensive purification, resulting in a higher melting point, increased whiteness, and lower oil content, making it ideal for cosmetic and pharmaceutical applications. Semi refined paraffin wax contains a higher oil content and less purity, which provides greater flexibility and cost-effectiveness suitable for industrial uses such as candle making and packaging. Selecting between fully refined and semi refined paraffin wax depends on the required purity level and application-specific performance.

Table of Comparison

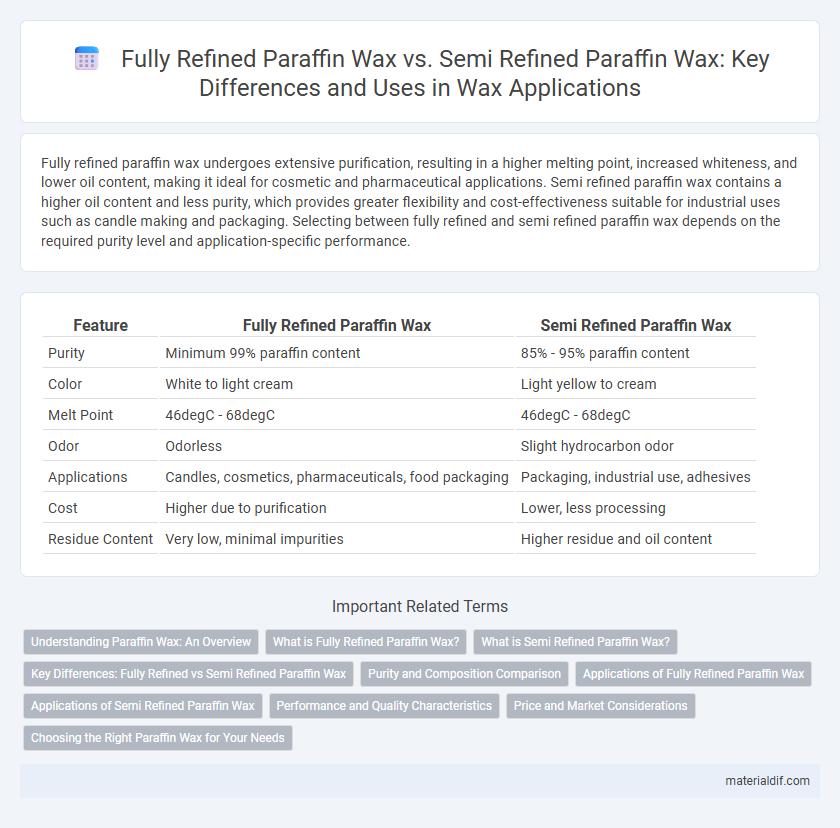

| Feature | Fully Refined Paraffin Wax | Semi Refined Paraffin Wax |

|---|---|---|

| Purity | Minimum 99% paraffin content | 85% - 95% paraffin content |

| Color | White to light cream | Light yellow to cream |

| Melt Point | 46degC - 68degC | 46degC - 68degC |

| Odor | Odorless | Slight hydrocarbon odor |

| Applications | Candles, cosmetics, pharmaceuticals, food packaging | Packaging, industrial use, adhesives |

| Cost | Higher due to purification | Lower, less processing |

| Residue Content | Very low, minimal impurities | Higher residue and oil content |

Understanding Paraffin Wax: An Overview

Fully refined paraffin wax contains minimal impurities with a high melting point, making it ideal for applications requiring purity and consistent performance such as cosmetics and pharmaceuticals. Semi-refined paraffin wax retains higher oil content and impurities, offering cost-effectiveness but with lower purity and variable melting points, suitable for industrial uses like candles and coatings. Understanding the refining process and resultant properties is essential for selecting the appropriate paraffin wax grade based on specific application requirements.

What is Fully Refined Paraffin Wax?

Fully Refined Paraffin Wax is a high-purity form of paraffin wax with a melting point typically ranging from 46 to 68 degrees Celsius, achieved through extensive refining processes that remove oil, sulfur, and other impurities. This wax exhibits superior whiteness, odorlessness, and hardness compared to Semi Refined Paraffin Wax, making it ideal for applications in cosmetics, pharmaceuticals, and food packaging. Its consistent quality and low oil content enhance performance in candle making, sealing, and coating industries.

What is Semi Refined Paraffin Wax?

Semi refined paraffin wax is a type of wax derived from the crude oil refining process, containing a higher level of impurities compared to fully refined paraffin wax. It has a melting point typically between 55-70degC and retains some oil content, making it suitable for applications such as candle making, packaging, and waterproofing. The semi refined version is less expensive but offers lower purity and clarity compared to fully refined paraffin wax.

Key Differences: Fully Refined vs Semi Refined Paraffin Wax

Fully refined paraffin wax contains less than 0.5% oil content, offering higher purity, better color clarity, and enhanced odorlessness, making it ideal for cosmetics and food applications. Semi refined paraffin wax has an oil content ranging from 0.5% to 1%, resulting in a slightly darker appearance and mild odor, suitable for industrial uses like candle making and packaging. The main differences lie in the refining process, purity levels, and typical applications, with fully refined wax being more processed for specialized needs.

Purity and Composition Comparison

Fully refined paraffin wax exhibits higher purity, containing over 99% saturated hydrocarbons with minimal impurities such as oil, sulfur, and color bodies. Semi refined paraffin wax has a lower purity level, typically containing 85-95% saturated hydrocarbons and higher residual oil, sulfur, and other impurities. This difference in composition affects the wax's odor, color, and performance in applications requiring high purity.

Applications of Fully Refined Paraffin Wax

Fully refined paraffin wax is widely used in industries requiring high purity and minimal odor, such as cosmetics, pharmaceuticals, and food packaging, due to its excellent chemical stability and consistent melting point. Its applications include candle making, where clean burning and bright whiteness are crucial, as well as coating and sealing in food processing to ensure safety and shelf life. The high degree of refinement makes it ideal for electrical insulation, providing superior dielectric strength compared to semi refined paraffin wax.

Applications of Semi Refined Paraffin Wax

Semi refined paraffin wax is widely used in applications such as candle making, packaging, and as a coating agent due to its moderate purity and cost-effectiveness. Its semi-purified nature allows it to retain some residual oil content, making it suitable for waterproofing paper and cardboard and enhancing adhesion in shoe polish and leather treatments. This type of wax also finds use in industrial processes requiring moderate melting points and good consistency, balancing performance with affordability.

Performance and Quality Characteristics

Fully refined paraffin wax offers superior purity with minimal impurities, resulting in a higher melting point, better color clarity, and enhanced odorlessness compared to semi refined paraffin wax. Semi refined paraffin wax contains more residual oil and impurities, which can lead to lower performance in applications requiring consistent hardness and smooth texture. The quality characteristics of fully refined wax make it ideal for cosmetics, food packaging, and pharmaceuticals, while semi refined wax suits industrial uses where absolute purity is less critical.

Price and Market Considerations

Fully refined paraffin wax commands a higher market price due to its purity and low oil content, making it ideal for applications requiring superior quality and safety standards. Semi refined paraffin wax, with higher oil content and impurities, is more cost-effective, catering to price-sensitive markets such as industrial uses and candle manufacturing. Market demand fluctuates based on application requirements, with fully refined wax dominating cosmetics and pharmaceuticals, while semi refined wax serves packaging and general-purpose uses.

Choosing the Right Paraffin Wax for Your Needs

Fully refined paraffin wax offers higher purity and fewer impurities, making it ideal for applications requiring food-grade or cosmetic standards. Semi refined paraffin wax contains more hydrocarbons and is often used in industrial processes like candle making and packaging. Selecting the right paraffin wax depends on factors such as intended use, purity requirements, and budget considerations.

Fully Refined Paraffin Wax vs Semi Refined Paraffin Wax Infographic

materialdif.com

materialdif.com