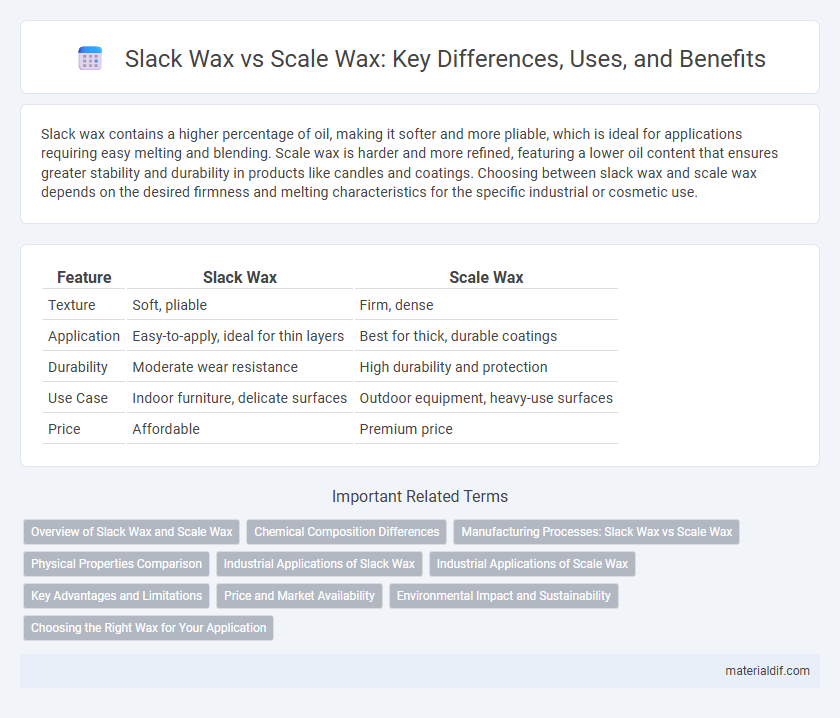

Slack wax contains a higher percentage of oil, making it softer and more pliable, which is ideal for applications requiring easy melting and blending. Scale wax is harder and more refined, featuring a lower oil content that ensures greater stability and durability in products like candles and coatings. Choosing between slack wax and scale wax depends on the desired firmness and melting characteristics for the specific industrial or cosmetic use.

Table of Comparison

| Feature | Slack Wax | Scale Wax |

|---|---|---|

| Texture | Soft, pliable | Firm, dense |

| Application | Easy-to-apply, ideal for thin layers | Best for thick, durable coatings |

| Durability | Moderate wear resistance | High durability and protection |

| Use Case | Indoor furniture, delicate surfaces | Outdoor equipment, heavy-use surfaces |

| Price | Affordable | Premium price |

Overview of Slack Wax and Scale Wax

Slack wax is a raw, unrefined petroleum wax containing a mixture of oil and wax with a low melting point, commonly used as a base for producing scale wax through refining processes. Scale wax, derived from slack wax, is a purified, refined wax with higher melting points and improved hardness, making it suitable for applications like candles, cosmetics, and polishes. The primary difference lies in the purity and melting characteristics, where slack wax serves as the raw intermediate product while scale wax is the finished, refined material optimized for industrial use.

Chemical Composition Differences

Slack wax contains a higher proportion of oil and impurities, typically comprising 30-40% oil content alongside paraffin wax and residual hydrocarbons. Scale wax is more refined, with a higher concentration of purified paraffin wax, usually above 80-90%, and minimal oil content. The differences in chemical composition influence their melting points, hardness, and suitability for various industrial applications.

Manufacturing Processes: Slack Wax vs Scale Wax

Slack wax is produced by dewaxing petrolatum or petroleum jelly through a solvent extraction process, resulting in a softer, impurity-rich wax with varying oil content. Scale wax, a more refined product, undergoes further refining steps such as filtration and hydrogenation to remove oils and impurities, yielding a harder, purer wax with consistent melting points. Manufacturing processes for slack wax emphasize separation of wax from oil, while scale wax production prioritizes purification and standardization for industrial applications.

Physical Properties Comparison

Slack wax exhibits higher viscosity and lower melting point due to its greater oil content, making it softer and more pliable than scale wax. Scale wax has a higher concentration of solid hydrocarbons, resulting in increased hardness, higher melting point, and greater brittleness. These physical properties influence their applications, with slack wax preferred for flexible formulations and scale wax favored for rigid, durable products.

Industrial Applications of Slack Wax

Slack wax, a byproduct of the petroleum refining process, is widely used in industrial applications such as candle making, rubber compounding, and adhesives due to its higher oil content and softer texture compared to scale wax. Its ability to enhance flexibility and improve surface finish makes slack wax ideal for coating, sealing, and molding operations in automotive and packaging industries. Unlike scale wax, which is harder and more brittle, slack wax offers superior compatibility with polymer blends and provides better processing efficiency in industrial manufacturing.

Industrial Applications of Scale Wax

Scale wax is widely used in industrial applications to prevent the buildup of mineral deposits and corrosion in pipelines and machinery, ensuring smoother operations and reducing maintenance costs. Unlike Slack wax, which is primarily utilized for candle production and coating purposes, scale wax's chemical properties enable it to act as an effective anti-scaling agent in harsh industrial environments. Its durability and resistance to high temperatures make scale wax essential in sectors like oil refining, water treatment, and chemical processing.

Key Advantages and Limitations

Slack wax offers a balanced mix of oil and wax, providing easier melting and better workability for candle making and cosmetics, but it tends to have lower purity and strength compared to scale wax. Scale wax, derived from refined hydrocarbon wax, boasts higher purity, hardness, and melting point, making it ideal for industrial applications that require strong structural integrity and durability. However, its higher melting temperature and brittleness can limit flexibility and ease of blending in formulations.

Price and Market Availability

Slack wax is generally cheaper than scale wax due to its lower refining level, making it more accessible for bulk industrial use. Scale wax commands a higher price because of its superior purity and consistent quality, favored in specialized applications like cosmetics and pharmaceuticals. Market availability of slack wax is broader, with easier sourcing from numerous oil refining residues, while scale wax is less abundant and often limited to premium suppliers.

Environmental Impact and Sustainability

Slack wax, a byproduct of the refining process, contains higher impurities and requires further purification, resulting in a larger environmental footprint due to increased energy consumption and chemical usage. Scale wax, derived from byproduct scale and often repurposed from industrial waste, demonstrates improved sustainability by utilizing materials that would otherwise be discarded, reducing overall waste and resource extraction. Selecting scale wax over slack wax supports circular economy principles and minimizes ecological impact in wax production.

Choosing the Right Wax for Your Application

Slack wax and scale wax differ in purity and usability; slack wax is a semi-refined byproduct with a mix of oil and wax, ideal for applications requiring flexibility such as candles and polishes. Scale wax, a more refined, pure form of wax, offers higher hardness and melting point, making it suitable for cosmetics, food coatings, and industrial uses. Selecting the right wax depends on the desired properties of the final product, including melting temperature, texture, and application-specific requirements.

Slack Wax vs Scale Wax Infographic

materialdif.com

materialdif.com